5

|

Maintenance

Service manual

374

REYQ8~20+REMQ5U7Y1B

VRV IV+ Heat Recovery

ESIE18-15B – 2020.05

5 Maintenance

5.1 Maintenance shedule

To ensure optimal availability of the unit, certain checks and inspections on the

unit and the field wiring have to be carried out at regular intervals. See the

checking procedures in this manual for inspection of the components mentioned

below.

The intervals depend on:

▪

Local legislation,

▪

the conditions at the installation site (presence of dust, sea salt, harmful gas, oil

mist, power supply fluctuation, bumps, vibration etc.),

▪

how the unit is operated (frequent stop and start, longer operation hours etc.),

▪

total running hours of the unit,

▪

ambient conditions (high heat and humidity load etc.)

Depending on the above mentioned factors, maintenance may be required sooner

than the mentioned interval here below.

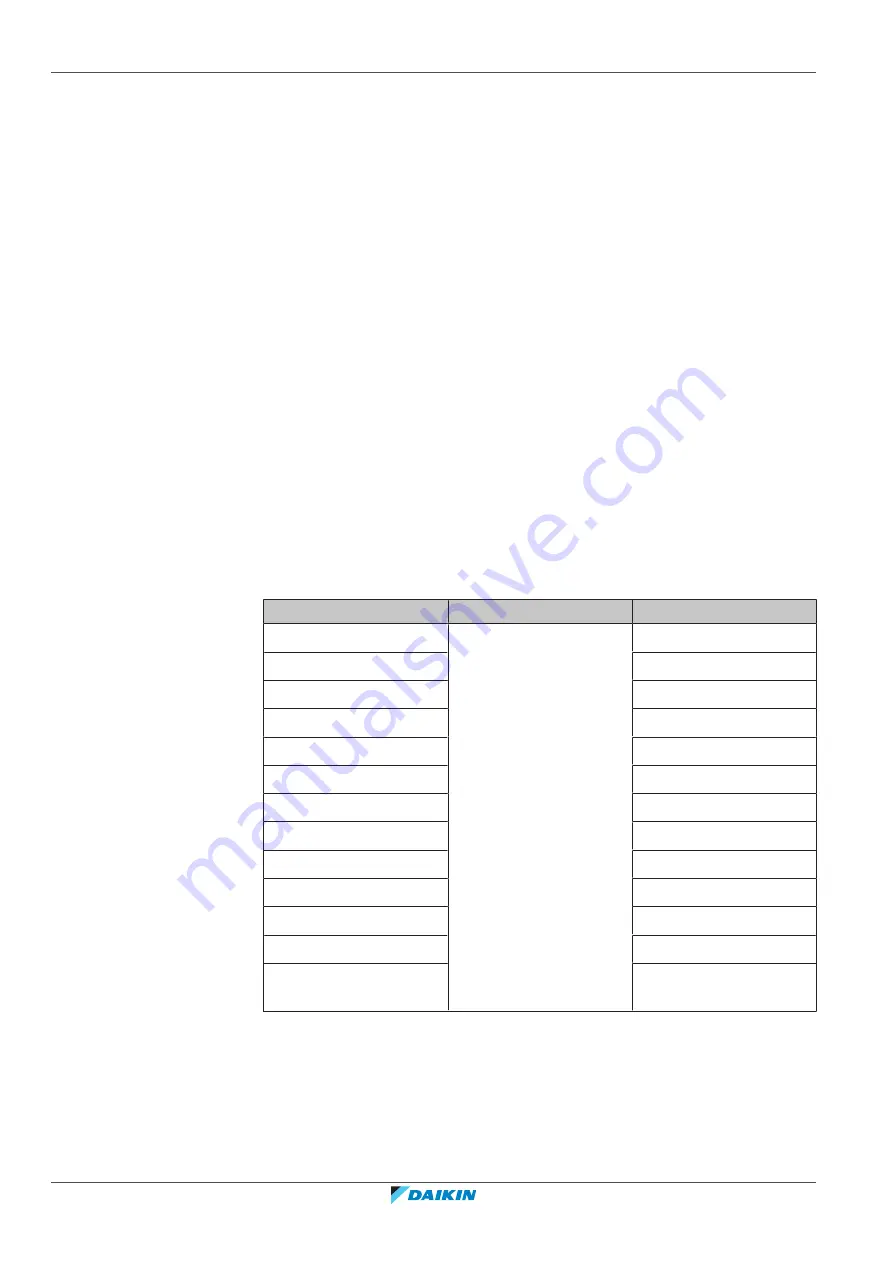

The table below also assumes a unit operation of 10 hours/day and 2500 hours/

year.

Normal use of the unit is considered when a unit is not performing the stop/start

cycle (Thermo OFF and then ON) more than 6 times/hour.

Component

Inspection

Maintenance

Electric Motor

1 year

20.000 hours

PCB

25.000 hours

Heat Exchanger

5 years

Sensor, Thermistor

5 years

User Interface, Switches

25.000 hours

Drain Pan

8 years

Expansion Valve

20.000 hours

Solenoid Valve

20.000 hours

Air Filter

5 years

High Efficiency Filter

1 year

Fuse

10 years

Crankcase Heater

8 years

Components under

pressure

In case of corrosion

Also, the cleaning of air filters, heat exchangers, fan propellers, drain pans etc. has

to be carried out at regular intervals, see

Summary of Contents for VRV IV+

Page 473: ......

Page 474: ......

Page 475: ......

Page 476: ...ESIE18 15B 2020 05 Copyright 2020 Daikin Verantwortung für Energie und Umwelt ...