Si-95

Test Operation

Test Operation Inverter K Series

47

1.3.2

Setting Mode 2

To enter setting mode 2 from setting mode 1 (normal), you must push and hold the MODE button (BS1) for

5 seconds. (Setting mode 2 cannot be entered while still making settings in setting mode 1.)

Setting procedure

1. Push the SET button and match with the setting item (LED display). (All 9 settings)

↓

2. Push the RETURN button (BS3) and the present settings flicker (LED display).

↓

3. Push the SET button (BS2) and match with each setting (LED flicker display).

↓

4. Push the RETURN button (BS3) and enter the settings.

↓

5. Push the RETURN button (BS3) and return to the initial status.

Note:

■

If you become unsure of how to proceed, push the MODE button (BS1) and return to setting mode 1.

■

The initial status of setting mode 2 is the status of setting item No. 1 in mode 2.

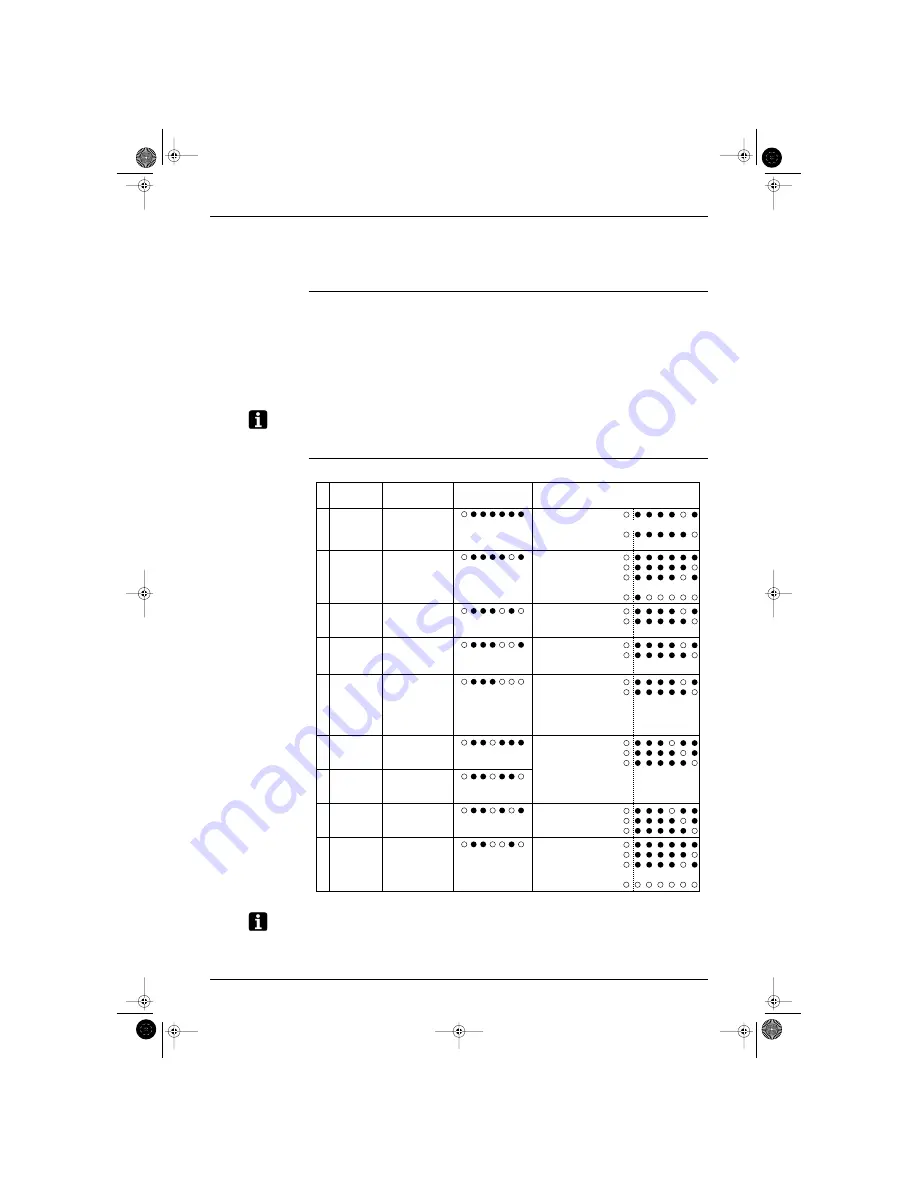

Setting items

Note:

∗

1 : Simultaneous cooling / heating operation is not possible by Emergency operation.

1

2

3

4

5

6

7

8

9

Setting item

EMG

∗

1

Low noise /

demand

address

Forced fan

switch

Indoor unit

forced

operation

Frequency

fix

Te setting

Tc setting

Defrost

setting

Not used

Description

Emergency

operation when

malfunction

occurs

Address for low

noise / demand

group operation

Fan of stopped

indoor unit turns

Allows operation

of indoor unit

from outdoor unit

Fixes the

frequency of the

inverter

compressor

5HP···68Hz

8.10HP··86Hz+ON

Low pressure

setting for

cooling

High pressure

setting for

heating

Temperature

setting for

defrost

Airnet address

LED display

H1P H2P H3P H4P H5P H6P H7P

LED display

H1P H2P H3P H4P H5P H6P H7P

Emergency operation

(Runs only by standard compressor)

Normal operation

Address

Binary number

(6 digits)

Forced fan operation

(H tap)

Normal operation

Indoor unit forced

operation

Normal operation

Frequency fix

Normal operation

High

Normal (factory set)

Low

Quick defrost

Normal (factory set)

Slow defrost

Address

Binary number

(6 digits)

0

1

2

~

63

0

1

2

~

31

~

~

(VF084)

SI-95.BOOK Page 47 Friday, March 31, 2000 10:59 AM