SiME332106E

Troubleshooting by Error Code

Part 6 Service Diagnosis

157

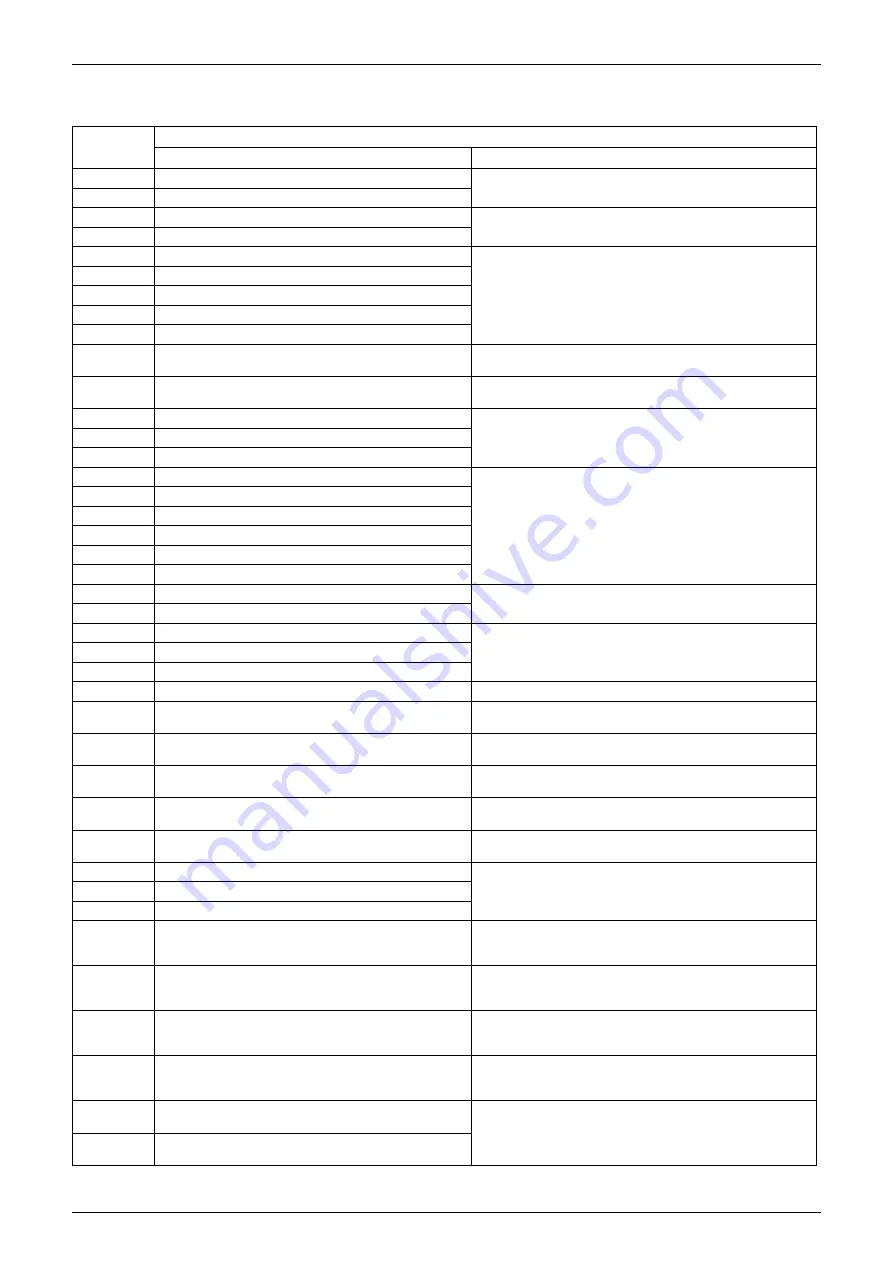

5.2.2 Outdoor Unit, System

Error code

Troubleshooting

Description of error

Diagnosis

E1 - 01

Outdoor unit PCB error

Refer to the

E1

flowchart and make a diagnosis based

on the Error code shown to the left.

E1 - 02

Defective outdoor unit PCB

E2 - 01

Earth leakage detection error

Refer to the

E2

flowchart and make a diagnosis based

on the Error code shown to the left.

E2 - 06

Missing of earth leakage detection core

E3 - 01

High pressure switch activated

Refer to the

E3

flowchart and make a diagnosis based

on the Error code shown to the left.

E3 - 02

High pressure switch activated

E3 - 07

High pressure switch activated (Batch)

E3 - 13

Liquid stop valve check error

E3 - 20

High pressure switch activated

E4 - 01

Low pressure error

Refer to the

E4

flowchart and make a diagnosis based

on the Error code shown to the left.

E5 - 01

Compressor M1C lock

Refer to the

E5

flowchart and make a diagnosis based

on the Error code shown to the left.

E7 - 01

Fan motor M1F lock

Refer to the

E7

flowchart and make a diagnosis

of the fan motor based

on the Error code shown to the left.

E7 - 05

Fan motor M1F instantaneous overcurrent

E7 - 09

Fan motor M1F IPM error

E9 - 01

Electronic expansion valve coil Y1E error

Refer to the

E9

flowchart and make a diagnosis

of the relevant electronic expansion valve based

on the Error code shown to the left.

E9 - 03

Electronic expansion valve coil Y2E error

E9 - 04

Electronic expansion valve coil Y3E error

E9 - 26

Electronic expansion valve coil Y4E error

E9 - 48

Electronic expansion valve overcurrent

E9 - 54

Defective circuit

F3 - 01

Discharge pipe high temperature error

Refer to the

F3

flowchart and make a diagnosis based

on the Error code shown to the left.

F3 - 23

Overload protector activated (Q1M)

F4 - 01

Wet alarm for compressor M1C

Refer to the

F4

flowchart and make a diagnosis based

on the Error code shown to the left.

F4 - 08

Wet error for compressor M1C

F4 - 14

Indoor unit failure alarm

F6 - 02

Excess refrigerant charge error

Excess refrigerant charge was detected during test run.

F6 - 03

Excess refrigerant charge warning

Excess refrigerant charge was detected

during operation other than test run.

H3 - 02

Connection error between main PCB and inverter PCB

Refer to the

H3

flowchart and make a diagnosis based

on the Error code shown to the left.

H5 - 01

Defective overload protector for M1C (Q1M)

Refer to the

H5

flowchart and make a diagnosis based

on the Error code shown to the left.

H7 - 21

Defective fan PCB for M1F

Refer to the

H7

flowchart and make a diagnosis based

on the Error code shown to the left.

H9 - 01

Defective outdoor air thermistor (R1T)

Refer to the

H9

flowchart and make a diagnosis based

on the Error code shown to the left.

J3 - 16

Defective discharge pipe thermistor (R21T): Open

Refer to the

J3

flowchart and make a diagnosis

based on the Error code shown to the left.

J3 - 17

Defective discharge pipe thermistor (R21T): Short

J3 - 56

Discharge pipe warning

J5 - 01

Defective suction pipe thermistor (R3T)

Refer to the

J5

flowchart and make a diagnosis

of the thermistor based

on the Error code shown to the left.

J6 - 01

Defective heat exchanger deicer thermistor (R7T)

Refer to the

J6

flowchart and make a diagnosis

of the thermistor based

on the Error code shown to the left.

J7 - 06

Defective subcooling heat exchanger liquid pipe

thermistor (R5T)

Refer to the

J7

flowchart and make a diagnosis

of the thermistor based

on the Error code shown to the left.

J8 - 01

Defective heat exchanger liquid pipe thermistor (R4T)

Refer to the

J8

flowchart and make a diagnosis

of the thermistor based

on the Error code shown to the left.

J9 - 01

Defective subcooling heat exchanger gas pipe

thermistor (R6T)

Refer to the

J9

flowchart and make a diagnosis

of the thermistor based

on the Error code shown to the left.

J9 - 08

Error detection of subcooling heat exchanger gas pipe

thermistor (R6T)