SiME332106E

Startup Control

Part 4 Functions and Control

53

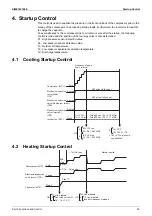

4. Startup Control

This control is used to equalize the pressure in the front and back of the compressor prior to the

startup of the compressor, thus reducing startup loads. Furthermore, the inverter is turned ON

to charge the capacitor.

To avoid stresses to the compressor due to oil return or else after the startup, the following

control is made and the position of the four way valve is also determined.

Pc : High pressure sensor detection value

Pe : Low pressure sensor detection value

Ta : Outdoor air temperature

Te : Low pressure equivalent saturation temperature

Td : Discharge temperature

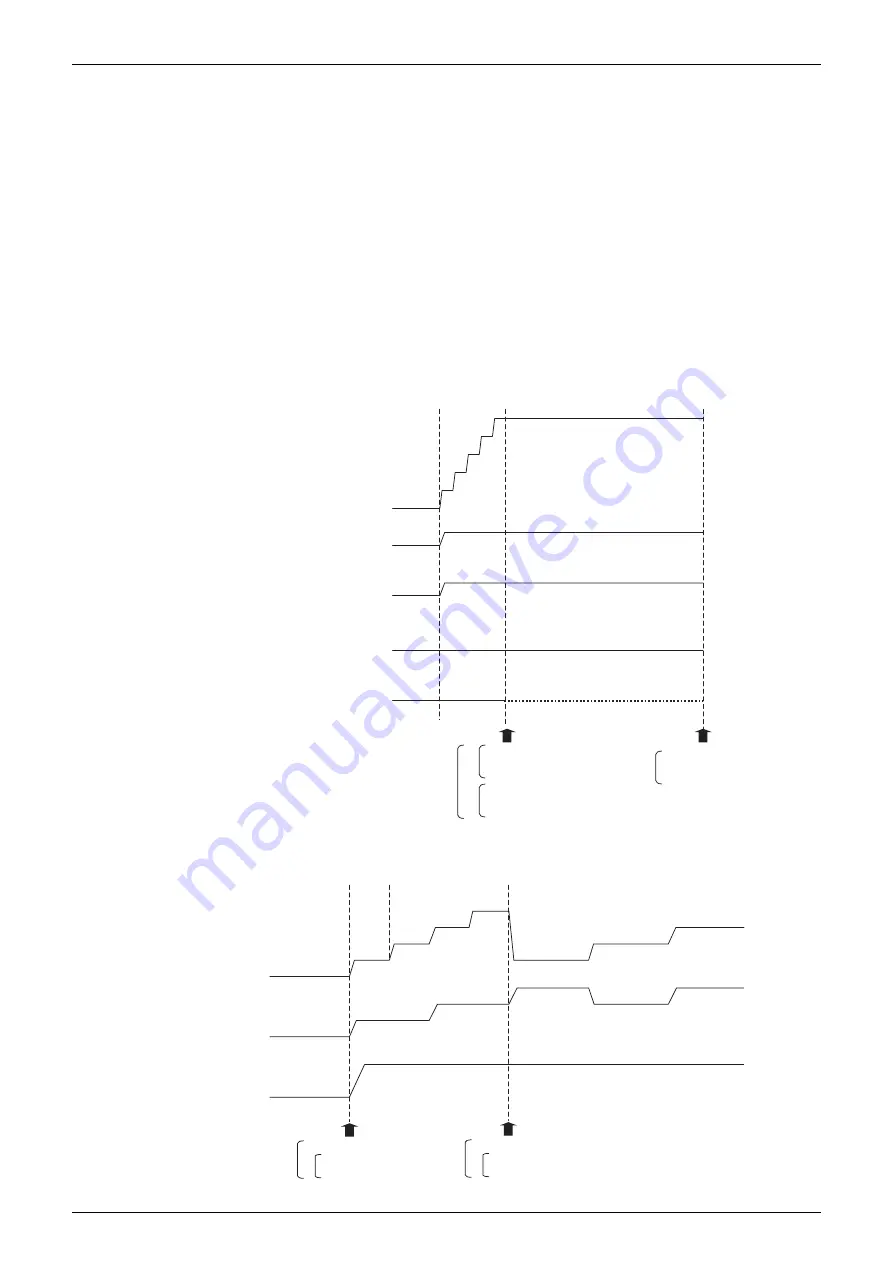

4.1 Cooling Startup Control

4.2 Heating Startup Control

0 Hz

0 pulse

480 pulse (fully open)

Step4

Te < 10°C

Te < Th2(

) – 10

&

INV

20 rps

Pc – Pe

0.42 MPa

&

INV > 20 rps

Pc – Pe

0.32 MPa

&

OR

Ta < 20°C: OFF

Ta

20°C: Step4

0 pulse

Frequency step up

5 sec. interval

+1step/15 sec. (Pc > 2.16 MPa)

–1step/15 sec. (Pc < 1.77 MPa)

Compressor (M1C)

Electronic expansion

valve (Main)

(Y1E)

0 pulse

480 pulse (fully open)

Electronic expansion

valve (Refrigerant jacket)

(Y3E)

Electronic expansion

valve (Injection)

(Y2E)

Inverter fan (M1F)

Th2 in "Pre-pressure

equalization"

0 Hz

Min.

step

15 sec.

Normal control

0 pulse

Step 4

Step 7Y

OR &

T (Ta – Te) control

45 sec. elapsed

10 sec. elapsed

Inverter frequency matched

Compressor (M1C)

Electronic expansion

valve (main) (Y1E)

Fan motor (M1F)

+15 Hz/20 sec.

OR &

15 min. elapsed

Four way valve ON

Td – Te > 10°C