3

1

10

• VRV Systems • Outdoor Units

111

• Outdoor Units • HEAT PUMP • RWEYQ-MY1

10

Installation of outdoor units

10 - 11Test run

C

AUTION

After completing installation, be sure to open the shutoff valve.

(Operating the unit with the valve shut will break the compressor.)

10 - 11 - 1 Air discharge

•

Running the heat source water pump, carry out air discharge process until the water comes out from the air discharge hole of local piping.

(For the operation to be done for the first time after installation, you need to perform a checking operation.)

10 - 11 - 2 Before turn on the power supply

•

Close the EL. COMPO. BOX cover securely before turning on power.

•

Make settings for outside unit PC board (A1P) after power-on and check the LED display from inspection door that is on the EL. COMPO. BOX

cover.

10 - 11 - 3 Check operation

(For the operation to be done for the first time after installation, you need to perform a checking operation according to this guideline without fail.

Otherwise, Abnormal Code “U3” appears and normal operation cannot be carried out.)

(1) Check the connection of interlock circuit

The outside unit cannot be operated if the interlock circuit has not been connected.

(2) As necessary, configure the system settings onsite by using the dip switch (DS1) and

push button switches (BS1 to 5) on the outside unit PC board (A1P).

After this, close the cover of electrical box.

Always perform configuration after turning ON the power. To learn the setting method,

refer to the [Service Precautions] label attached at the cover of electrical box shown in the

figure 27. Remember, the actual settings you have made must be recorded on the

[Service Precautions] label.

(3) Turn ON the power to the outside units and indoor units.

Make sure to turn ON the power 6 hours before starting the operation.

This is necessary to warm the crankcase by the electric heater.

(4) Start the heat source water pump and fill the heat source water in the outside unit.

The outside unit cannot be operated if the heat source water pump is not running.

(5) Make sure that the temperature of heat source water is kept within the operation

range (10 - 45°C).

The outside unit cannot be operated at a temperature outside the operation range.

(6) Check the LED on the PC board (A1P) in the outside unit to see if the data transmission is performed normally.

(*) The master unit is the outside unit to which the transmission wiring for the indoor units is connected.The other outside units are sub units.

(7) •

Using the push button switches (BS1 - 5) on the P-panel (A1P) of outside unit,

carry out a local setting, if necessary.

•

In case of an installation of multiple outside units, carry out the setting on the

master unit.

(Setting on the slave unit becomes invalid.)

Always carry out the setting

only after the power supply has been applied.

For the method of setting, refer to the label of “

Points to be noted when providing

services

” attached to the cover of electrical box (shown in the figure 27) of the outside

unit.

(After setting, record the details of that setting to the label of “Points to be noted when

providing services” without fail.)

(8) Check all shutoff valve is opened.

If some shutoff valve is closed, open them.

(Refer to “9-10 Shutoff valve operation procedure”.)

C

AUTION

Do not leave any shutoff valve closed.

Otherwise the compressor will fail.

For Heat recovery system of cooling and heating:

Open all stop valves on the suction side, discharge gas side and liquid side.

For cooling and heating switching operation system:

Open the stop valves on discharge gas side and liquid side. (

Keep the stop valve on

suction side fully closed.

)

(9) Perform the check operation following

If you push the test run button (BS4) on the P-panel (A1P) of the outside unit.

for 5 seconds, the test run starts.

If you want to interrupt the test run, push the RETURN button (BS3) on Ppanel (A1P) of

the outside unit. The system continues residual operation for about 1 minute (maximum

10 minutes) and then stops.

(During test run, you cannot stop it by a command from a remote controller.)

Carry out above setting from a service window.

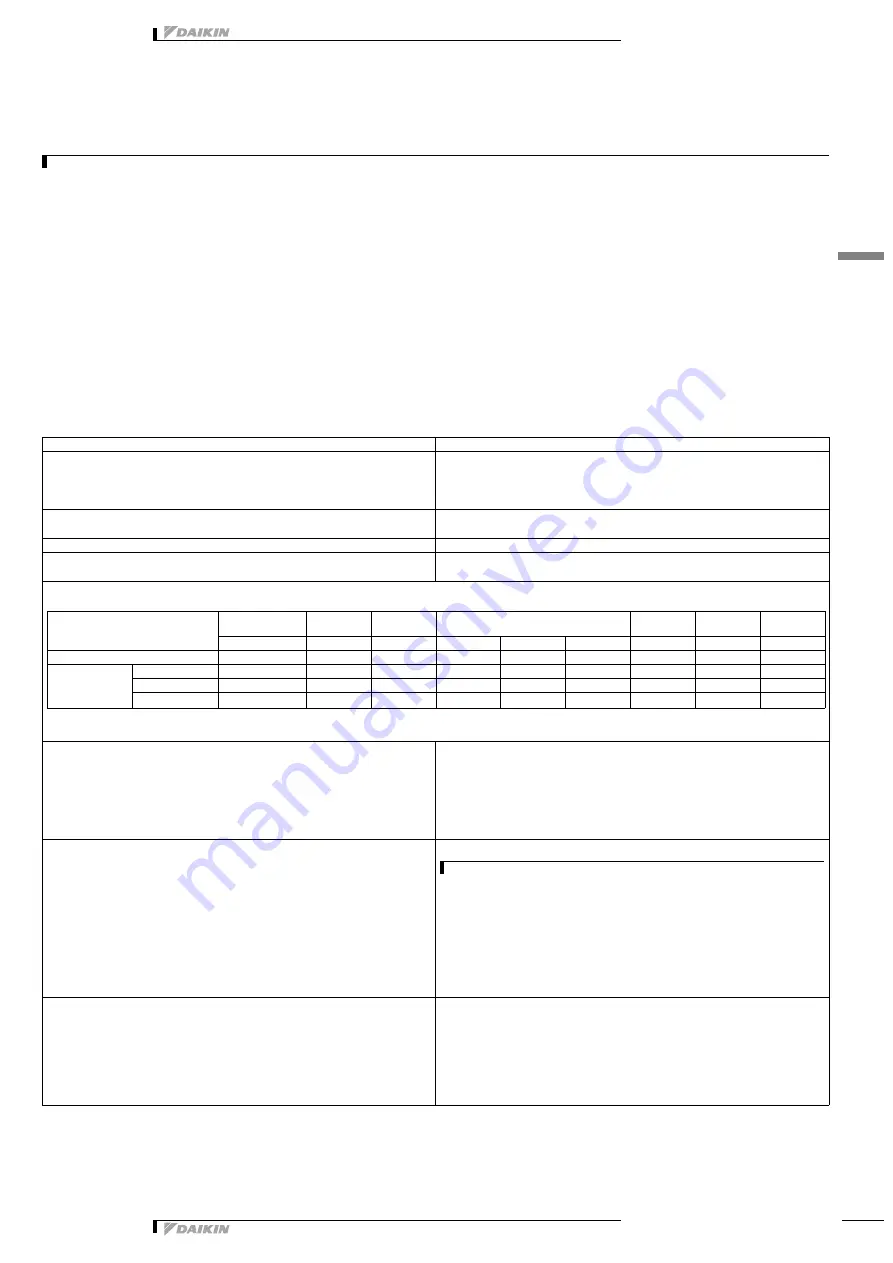

LED display

(Default status before delivery)

Microcomputer

operation monitor

Page

Ready/Error

Cooler/heater changeover

Low noise

Demand

Multi

HAP

H1P

H2P

H3P

H4P

H5P

H6P

H7P

H8P

One outside unit installed

9

7

7

8

7

7

7

7

7

When multiple

outside unit

installed (*)

Master station

9

7

7

8

7

7

7

7

8

Sub station 1

9

7

7

7

7

7

7

7

9

Sub station 2

9

7

7

7

7

7

7

7

7

LED display:

7

OFF

8

ON

9

Blinking