IOM 1281-2 • CENTRIFUGAL WATER CHILLERS 26 www.DaikinApplied.com

Installation

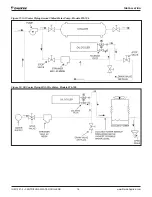

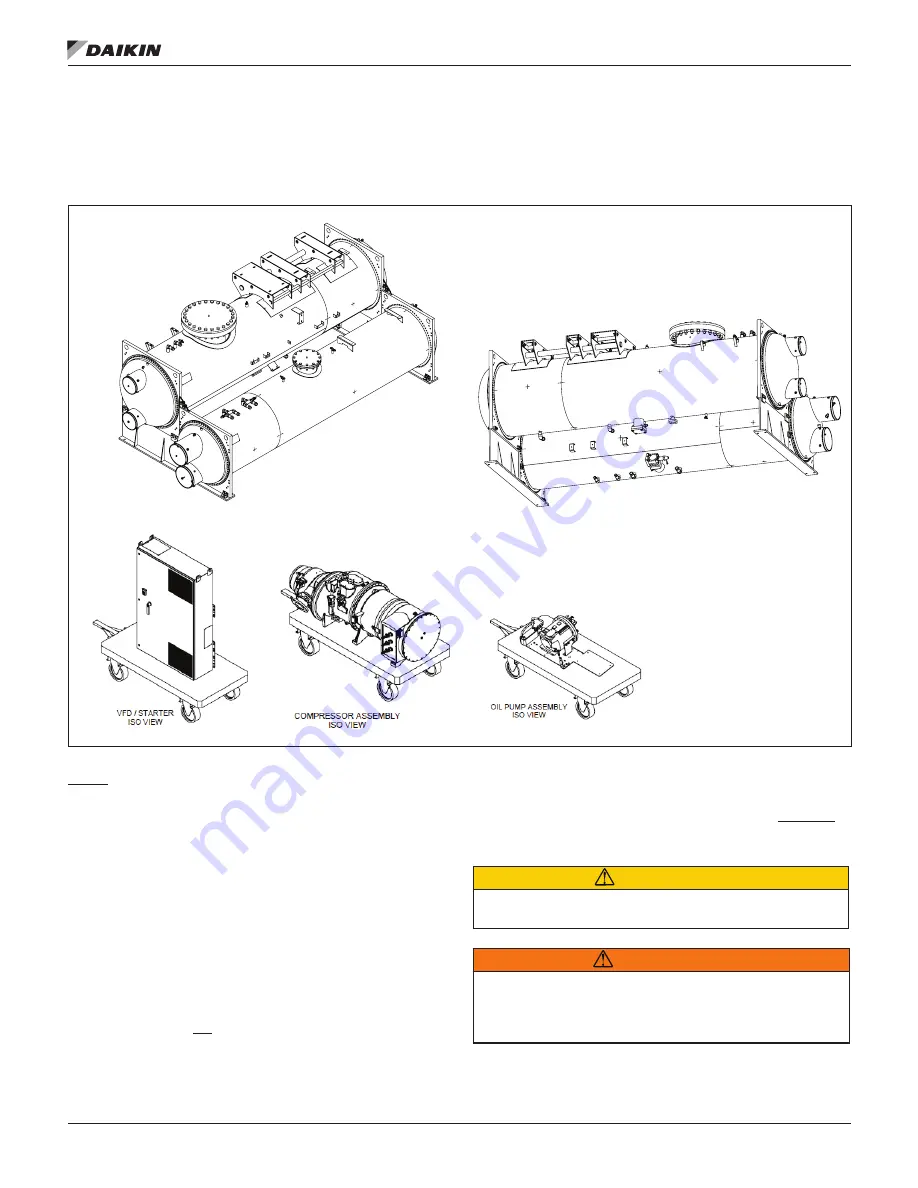

Partial Disassembly Construction - Type B

Compressor(s), power box(es), and control box are removed at the factory and shipped on separate skids; combined vessel stack

is shipped together as a sub-assembly.

Figure 20: Partial Disassembly Construction Option - Representative Schematic

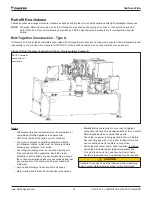

Scope:

• Site reassembly must be supervised or completed

by Daikin Applied service personnel. Cost for unit

reassembly and supervision by Daikin Applied service

is not included in the purchase price of the equipment.

Contact Daikin Applied service for pricing.

• Unit is fully tested at the factory prior to disassembly and

shipment.

• All associated piping and wiring remain attached, if

possible. Suction and discharge lines have bolt-on

flanges and, if possible, remain attached. If the stack size

or weight dictates further disassembly, the vessels can

be separated by disconnecting any interconnecting wiring

and tubing and then unbolting them.

• Refrigerant will not be shipped with the chiller and must

be procured by others. Compressor(s) and vessels

receive an inert gas holding charge that must be released

prior to attempting to open any connection.

•

All free piping ends are capped, blockoffs will cover all

compressor and vessel openings.

• Unit ships with vessel and/or head insulation, if ordered.

• Unit ships with replacement refrigerant gaskets and

O-rings, stick-on wire ties, and touch-up paint.

CAUTION

Standard torque specs must be followed when re-installing

bolts. Contact Daikin Applied service for this information.

WARNING

Remove compressor, piping or vessel holding charge through

the Schrader valve in the block off plates before attempting to

loosen any fittings on them. Failure to do so can cause severe

bodily injury.

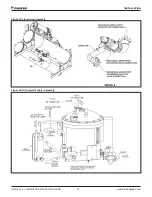

VIEW 1

SUCTION & DISCHARGE

BLOCKOFF PLATES

HOT GAS BYPASS

(OPTIONAL)

LIQUID LINE

SUCTION

DISCHARGE

VIEW 2

LIQUID LINE & HOT GAS BYPASS

BLOCKOFF PLATES

Interconnecting piping to be crated

along with gaskets, o-rings, clamps,

brackets, and additional unit

hardware:

•

Oil lines

•

Liquid injection line

•

Motor cooling lines

•

Motor drain line

•

Suction elbow

•

Discharge line

•

Liquid line

•

Oil cooler refrigerant lines