Installation

www.DaikinApplied.com 27

IOM 1281-2 • CENTRIFUGAL WATER CHILLERS

Table 7: Vessel Component Weights

* Component weights based on largest unit with standard tube configuration.

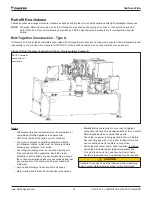

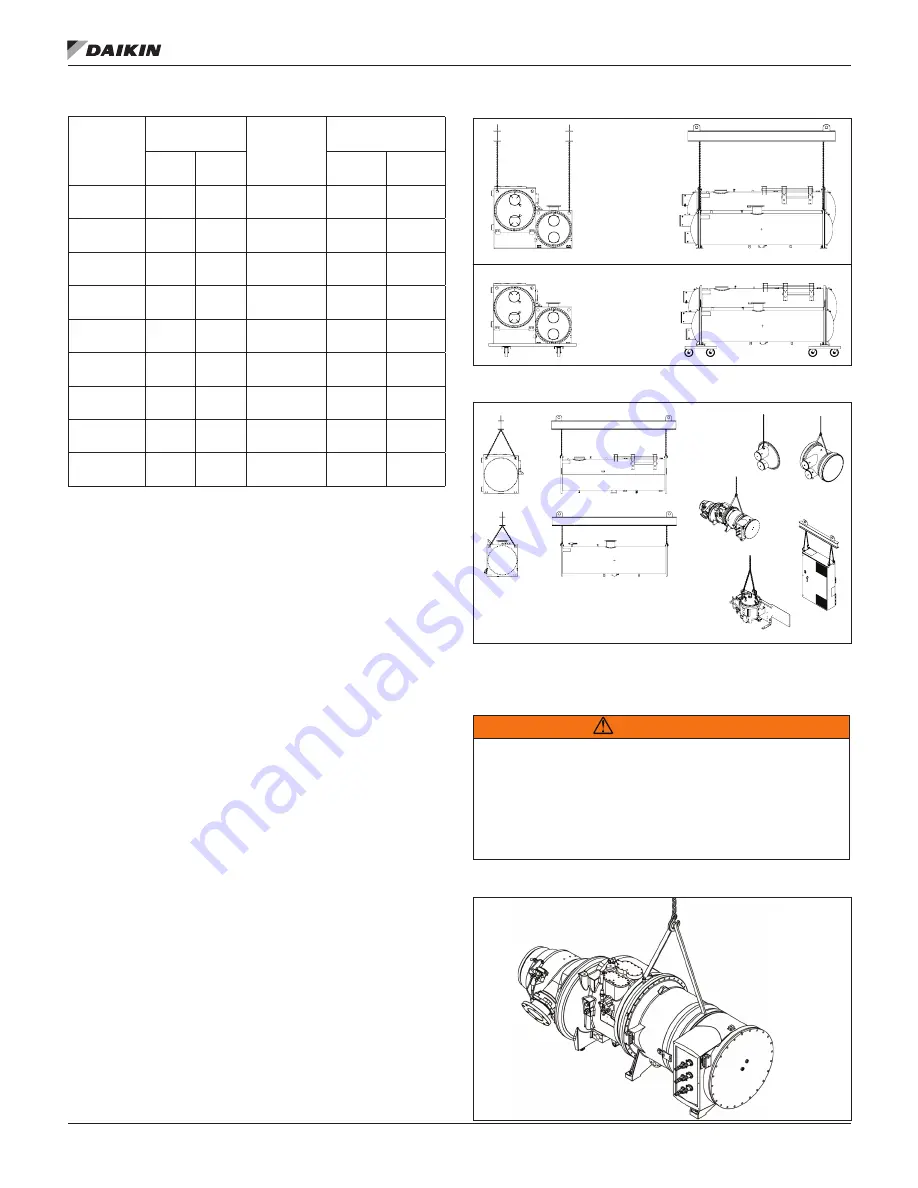

Knockdown Rigging/Lifting Guidelines

To properly rig or lift separated assemblies and components,

consult a licensed, certified rigging specialist.

• Lifting holes located in the tubesheets should be used to

attach chain hoists for moving connected vessel stacks

or individual evaporator/condenser assemblies. Rolling

dollies supporting the full vessel width may also be used

under the tubesheets on each end.

• Lift the VFD / Starter by attaching chain hoists to the

lifting brackets located at the top corners of the cabinet.

Rolling dollies supporting the full cabinet width may also

be used.

• Lift the oil pump assembly by attaching eye bolts in the

2 holes on the top of the oil pump and then connect the

chain hoists. Eye bolts are not provided. Rolling dollies

may also be used.

• Lift dished waterbox head assemblies by attaching chain

hoists to the lifting lugs on the head. The location of the

lifting lug will vary depending on size of the waterbox and

nozzle configuration. Rolling dollies may also be used.

• Lift marine waterbox head assemplies by wrapping lifting

straps around the body of the waterbox. Rolling dollies

may also be used.

• Lift the compresser by wrapping lifting straps around

the body of the assembly, see

Figure 23.

Rolling dollies

supporting the full length of the compressor may also be

used.

Note component weights and dimensions are listed in

Table 7

and Table 8.

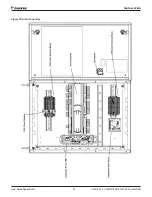

Figure 21: Vessel Stack Lifting/Rigging Setup

Figure 22: Component Lifting Setup

NOTE:

The spreader bar in

Figure 21

and

Figure 22

are representations only and may not reflect the

appearance of the actual spreader bar needed.

WARNING

Improper rigging, lifting, or moving of a unit can result in

property damage, severe personal injury or death. Follow

rigging and moving instructions carefully. Daikin Applied is not

a licensed nor certified rigging specialist. It is the customer’s

responsibility to consult a certified rigging contractor to rig,

lift, and move components and subcomponents properly and

safely.

Figure 23: Compressor Lifting Setup - Closeup

Evaporator

Dry Weight

Condenser

Dry Weight

lbs

kg

lbs

kg

3016-WDC

5235

2374

3016-WDC

5869

2662

3616-WDC

6928

3142

3616-WDC

8197

3718

4216-WDC

12025

5454

4216-WDC

14489

6572

4816-WDC

16800

7620

4816-WDC

19412

8805

4220-WDC

14988

6798

4220-WDC

18284

8293

4820-WDC

20523

9309

4820-WDC

23724

10761

3620-WCC

8756

3971

3620-WCC

11893

5394

4220-WCC

12674

5748

4220-WCC

16856

7645

4820-WCC

18495

8389

4820-WCC

21993

9975

BACK VIEW

END VIEW

BACK VIEW

END VIEW

VESSEL STACK - LIFTING

VESSEL STACK - RIGGING

CONDENSER ASSEMBLY

BACK VIEW

TUBE PATTERN

NOT SHOWN

CONDENSER ASSEMBLY

END VIEW

EVAPORATOR ASSEMBLY

BACK VIEW

TUBE PATTERN

NOT SHOWN

EVAPORATOR ASSEMBLY

END VIEW

HEAD ASSEMBLY

ISO VIEW

WATERBOX ASSEMBLY

ISO VIEW

COMPRESSOR ASSEMBLY

ISO VIEW

VFD / STARTER

ISO VIEW

OIL PUMP ASSEMBLY

ISO VIEW

FIELD - FULL KNOCKDOWN

LIFTING