Operation

www.DaikinApplied.com 37

IOM 1281-2 • CENTRIFUGAL WATER CHILLERS

Complete STATUS Text

(in priority sequence)

Notes

RUN Unload Vanes-Lag Start

Overrides water temperature

command

RUN Hold Vanes-Evap Press

RUN Unload Vanes-Evap

Press

RUN Unload Vanes-Soft Load

RUN Hold Vanes-Soft Load

RUN Load Vanes-Disch Temp

RUN Hold Vanes-Pull-down

Rate

RUN Unload Vanes-Demand

Limit

RUN Hold Vanes-Min Amps

RUN Load Vanes

Normal operation

RUN Hold Vanes

RUN Unload Vanes

SHUTDOWN Unload

Unloading during the shutdown

sequence

POSTLUBE Timer=xxx

Postlube timer on

POSTLUBE Motor Current

High

Compressor motor running

during the shutdown mode. It

should be off.

NOTE:

Timer countdown values will be shown in place of

“xxx”.

For a VFD equipped compressor, “Vanes” or “Speed”

is shown in the RUN state to indicate if the capacity is

controlled by speed from the VFD or by vane control.

The bottom icon bar will be visible on all screens with the

active screen highlighted in white.

(II) Unit Status Modes

- Defined by Mode followed by State.

If the unit is stopped, the Source would be listed after State.

Various unit states and control sources are shown as examples

in

Figure 35 to Figure 37.

Figure 35: Mechanical Switch Source

Figure 36: Digital Remote Switch Source

Figure 37: BAS Network Source

(III) Additional Home View Trend Data Graphs

• Entering and leaving evaporator water temperatures

• Entering and leaving condenser water temperatures

• Percent compressor RLA

• Compressor kW (will read 0 without Full Metering Option

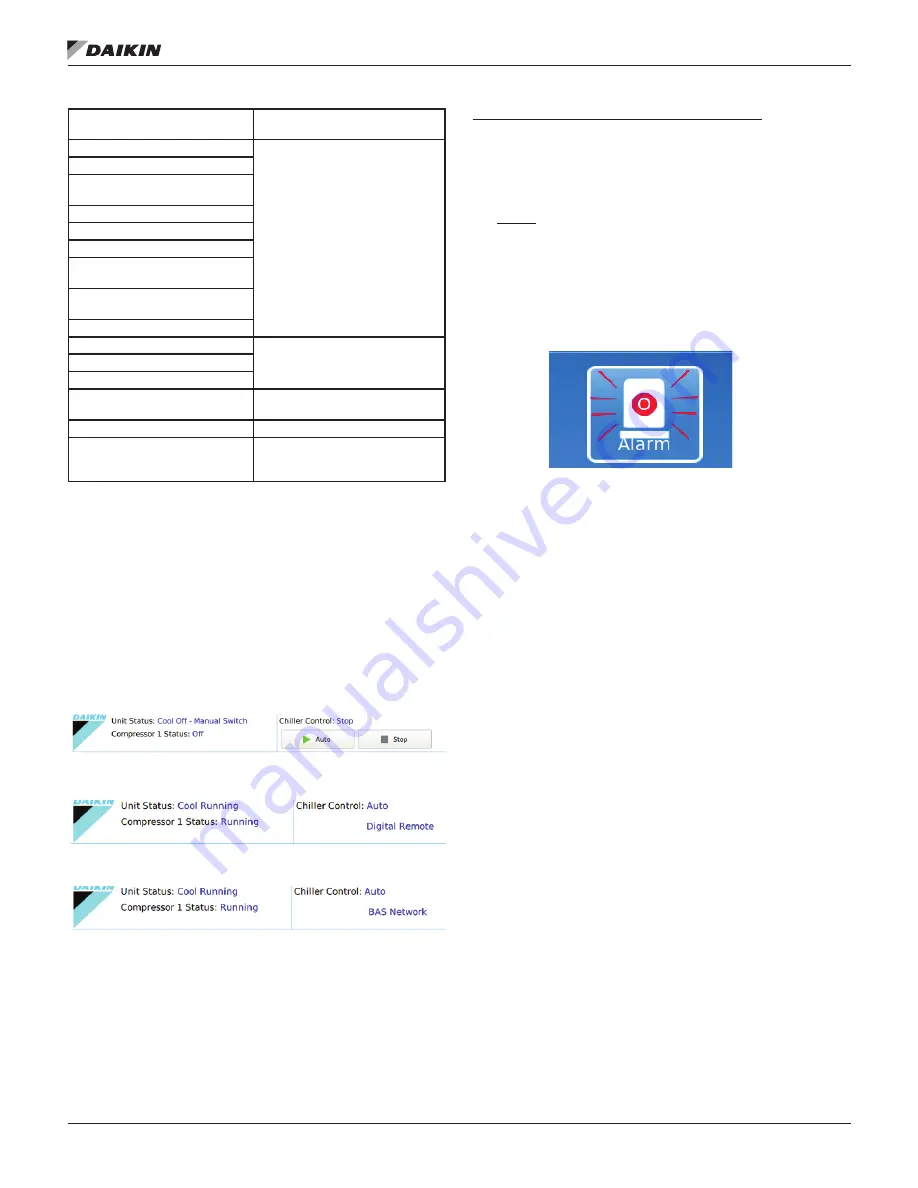

(IV)

Alarm

•

The ALARM icon will turn red and begin flashing should

an alarm occur. This red ALARM button will appear on

all screens in the case of an alarm. See

Figure 38

for an

example of an active alarm alert. For more information on

alarms, see

page 56

.

Figure 38: Active Alarm Icon

Additional HMI View Screens

Pressing the Detail Tab on the top of the Home View Screen

provides specific unit operating parameters shown in

Figure

39

. Chiller Model “WCF” is the general software category for

WSC, WDC, WCC, and TDC models (see

“Figure 50: Settings View - Modes” on page 47

).

If a Technician level password is entered, two additional

tabs will follow the Detail Tab. The Tech Data Tab will show

compressor staging and pLAN communication.

On the Tech

I/O Tab, the technician will find all inputs and outputs, both

analog and digital, at both the Unit Controller and Compressor

Controller levels.

To make setpoint adjustments or change operating parameters,

tap on the Settings icon at the bottom of the screen;

Figure 47

on page 45.