IOM 1281-2 • CENTRIFUGAL WATER CHILLERS 40 www.DaikinApplied.com

Operation

The Compressor State Information on the right side of the

screen is a compilation of the events that the chiller sequences

through at startup. A green light indicates that a particular

sequence requirement has been satisfied. It is recommended

that this information be viewed during the startup sequence.

One can see the requirements light up as they are met and

also determine why a non-start may have occurred. Similarly

during the shut down process, the sequence transitions back to

“Off” and the highlight color will switch to black.

The left side information displays the status of the compressor

inputs and outputs in greater detail than on the Home Detail

screen (

Figure 39

). Compressor information will populate in the

Power data box if the Full Metering card has been installed and

wired; otherwise zeros will be shown or the Power box will not

display on the HMI. Compressor related setpoint adjustments

can be made within the Settings screen on the Modes and

Motor tabs.

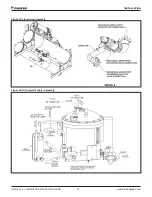

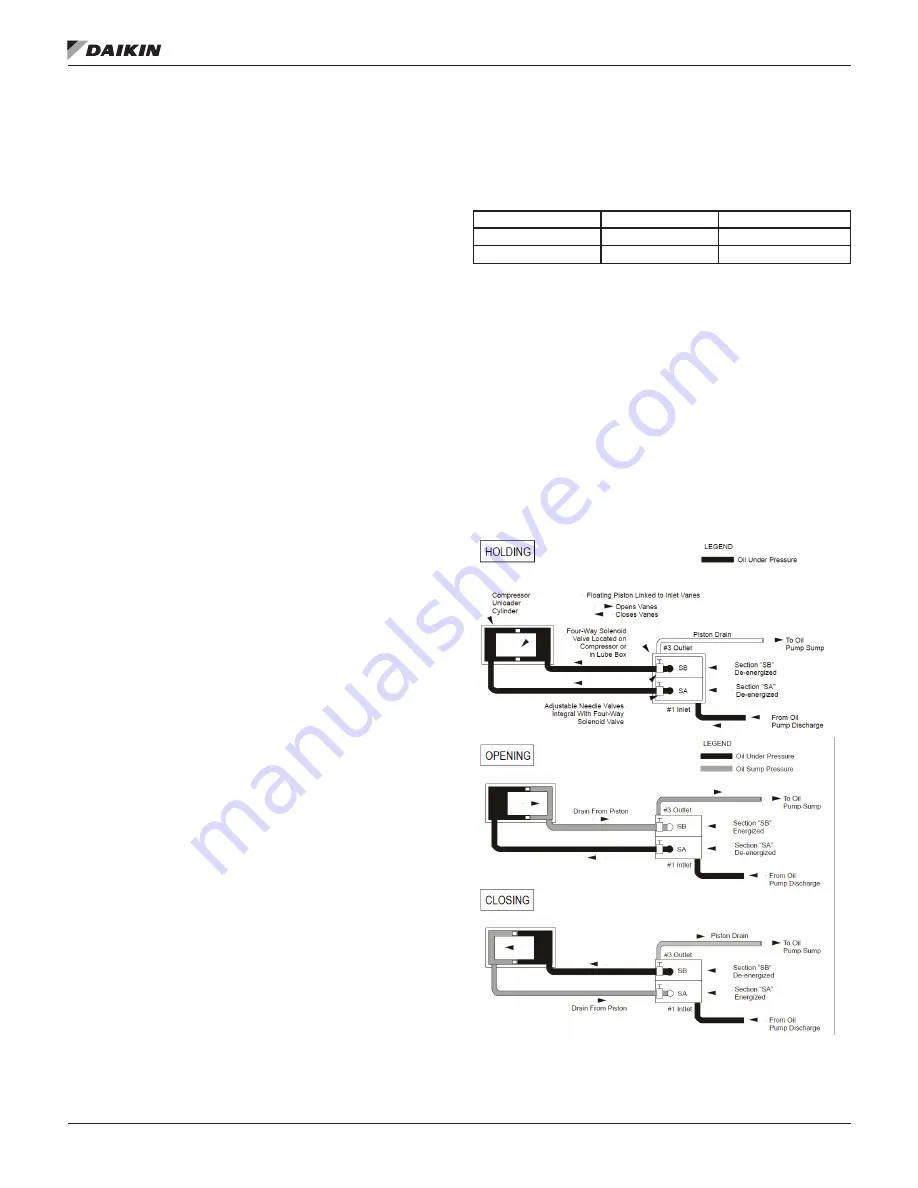

Capacity Control System

The opening or closing of the inlet vanes controls the quantity

of refrigerant entering the impeller thereby controlling the

compressor capacity. For 079-126 compressor models,

the vane movement occurs in response to oil flow from the

vane load/unload SA or SB 4-way solenoid valves, which in

turn, respond to instructions from the unit microprocessor

as it senses leaving chilled water temperature. This oil flow

activates a sliding piston that rotates the vanes.

Vane Operation

The hydraulic system for the inlet guide vane capacity

control operation consists of a 4-way normally open solenoid

valve located in the oil management control panel or on the

compressor close to the suction connection. Oil under pressure

from the oil filter is directed by the 4-way valve to either or both

sides of the piston, depending on whether the control signal is

to load, unload, or hold as illustrated in

Figure 42

.

To open the vanes (loading compressor), solenoid SA is de-

energized and SB is energized, allowing oil flow from port SA

to one side of the piston; other side drains through port SB.

To close the vanes (unload compressor), valve SB is de-

energized and valve SA is energized to move the piston and

vanes toward the unload position.

When both solenoid valves SA and SB are de-energized, full

oil pressure is directed to both sides of the piston through ports

SA and SB, and the vanes are held in that position. Refer to

Figure 43 on page 42

for solenoid action. Note that both

solenoids cannot be energized simultaneously.

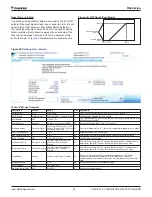

Vane Speed Metering Valves

The speed at which the capacity control vanes are opened or

closed can be adjusted to suit system operating requirements.

Adjustable needle valves in the oil drain lines are used to

control the rate of bleed-off and consequently the “vane

speed”. These needle valves are part of the 4-way solenoid

valve assembly located in the compressor lube box. For unit

and system balancing through pLAN communication, it is

important to have the Opening (Load) and Closing (Unload)

speeds be as close as possible and must be within 30 seconds

of each other. The valves are factory set so that the vanes will

move from fully closed to fully opened in the times shown in

Table 11.

Table 11: Vane Speed Factory Setting

Compressor Model

Opening Time

Closing Time

CE079 - CE100

3 - 5 min.

3 - 5 min.

CE126

5 - 8 min.

5 - 8 min.

The start-up technician may readjust the vane speed at

initial start-up to meet job conditions. The speed must be

slow enough to prevent over-controlling and hunting. These

adjustments are sensitive. Turn the adjusting screws a few

degrees at a time.

The left adjusting screw is the SB needle valve for adjusting

the vane OPENING speed for loading the compressor. Turn

this screw clockwise to decrease the vane opening speed and

counterclockwise to increase the opening speed.

The right adjusting screw is the SA needle valve for adjusting

the CLOSING speed to unload the compressor. The same

adjustment method applies - clockwise to decrease closing,

counterclockwise to increase vane closing.

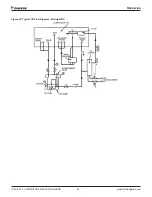

Figure 42: Vane Control Solenoid Operation .