Operation

www.DaikinApplied.com 41

IOM 1281-2 • CENTRIFUGAL WATER CHILLERS

Capacity Overrides

Compressor capacity is determined by the status of the leaving

chilled water temperature (LWT), which is a direct indicator

of whether the chiller is producing enough cooling to satisfy

the cooling load. The LWT is compared to the active chilled

water setpoint, and compressor loading or unloading ensues,

considering any capacity overrides that may be in effect.

The unit may experience a condition that will override normal

capacity control. Of the following limits, the one creating the

lowest capacity limit is in effect.

Low Evaporator Pressure

If the evaporator pressure drops below the Low Evap Pressure

– Inhibit setpoint, the unit will inhibit capacity increases. If the

evaporator pressure drops below the Low Evap Pressure -

Unload setpoint, the unit will begin capacity decreases.

High Motor Temperature

If the highest motor stator temperature is above the limit, the

unit will adjust capacity to keep the temperature within the

limits.

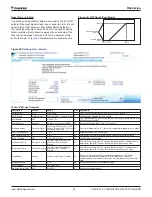

Demand Limit

The maximum amp draw of the compressor(s) can be limited

by a 4 to 20 mA signal on the Demand Limit analog input.

This function is only enabled if the Demand Limit Enable

setpoint is set to ON. The amp limit decreases linearly from the

Maximum Amp Limit setpoint (at 4 mA) to the Minimum Amp

Limit setpoint (at 20mA). While this override is in effect, chiller

capacity is continuously adjusted to keep the % RLA near the

requested demand limit.

Network Limit

The maximum amp draw of the compressor (s) can be limited

by a value sent through a BAS network connection and stored

in the Network Limit variable. While this override is in effect,

chiller capacity is continuously adjusted to keep the % RLA

near the requested demand limit.

Maximum Amp Limit

The maximum amp draw of the compressor(s) is always limited

by the Maximum Amps setpoint. This limit has priority over all

other functions including manual capacity control. While this

override is in effect, chiller capacity is continuously adjusted to

keep the % RLA near the limit value.

Hot Gas Bypass

All units can be equipped with an optional hot gas bypass

system that feeds discharge gas directly into the evaporator.

Light load conditions are signaled by measurement of the

percentage of RLA by the MicroTech controller. When the RLA

drops to the setpoint, the hot gas bypass solenoid valve is

energized, making hot gas bypass available for metering by

the hot gas regulating valve. This hot gas provides a stable

refrigerant flow and keeps the chiller from short cycling under

light load conditions, while also reducing surge potential on

heat recovery units.

The factory default setpoint for bringing on hot gas bypass is

20% of RLA and is adjustable on Settings - Modes tab shown

on

“Figure 50: Settings View - Modes” on page 47

.

Surge and Stall

Stall and surge are characteristics of all centrifugal

compressors. These conditions occur when low load combines

with high compressor lift. In a stall, discharge gas has

insufficient velocity leaving the impeller to reach the volute

and just “sits” or stalls in the diffuser section. The compressor

sound level goes way down due to no flow and the impeller

starts to heat up. In surge, the heated discharge gas alternately

flows back through the impeller and then reverses to the volute

about every two seconds. Extreme noise and vibration occur.

The compressor is equipped with a temperature sensor that

shuts it off if these conditions occur.

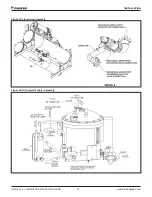

Lubrication System

The lubrication system provides lubrication and heat removal

for compressor bearings and internal parts. In addition, the

system provides lubricant under pressure to hydraulically

operate the unloading piston for positioning the inlet guide

vanes for capacity control. WDC, dual compressor chillers,

have completely independent lubrication systems for each

compressor.

Only the recommended lubricant can be used for proper

operation of the hydraulic system and bearing lubrication

system. Each unit is factory-charged with the correct amount

of the recommended lubricant. Under normal operation, no

additional lubricant is needed. Lubricant must be visible in the

sump sight glass at all times.

Compressor sizes, CE079 through CE126, utilize a separate

lubricant pump located in the sump. The sump includes the

pump, motor, heater and lubricant/vapor separator system. The

lubricant is pumped through the external oil cooler and then

to the oil filter located inside the compressor housing. Oiled

centrifugal models 079-126 units utilize a water-cooled oil

cooler for the compressor. The oil coolers maintain the proper

oil temperature under normal operating conditions. The coolant

flow control valve maintains 95°F to 105°F (35°C to 41°C).

Lubrication protection for coast down in the event of a power

failure is accomplished by a spring-loaded piston in models

CE079 through 087. When the oil pump is started, the piston is

forced back against the spring by the oil pressure, compressing

the spring, and filling the piston cavity with oil. When the pump

stops, the spring pressure on the piston forces the oil back

out to the bearings. In compressor model CE 100 - 126 the

compressor coast down lubrication is supplied from a gravity-

feed oil reservoir.