Operation

www.DaikinApplied.com 59

IOM 1281-2 • CENTRIFUGAL WATER CHILLERS

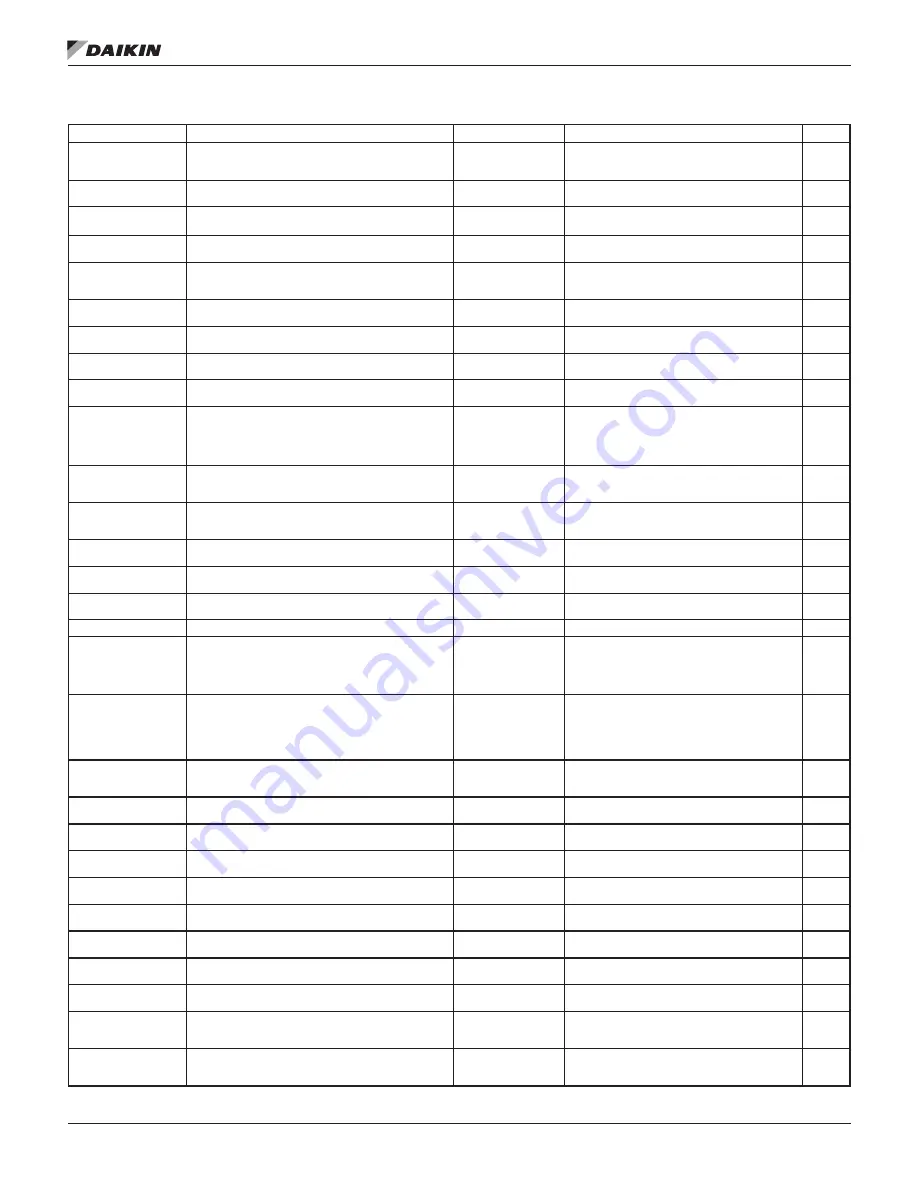

Table 19: Critical Alarms

Screen Text

Occurs When

Action Taken

Troubleshooting

Clear

Evaporator Pressure

Low

Evaporator Press < Low Suction Pressure-Stop SP for

60 sec. Delay reduces linearly to 10 sec at 10 psi below

SP, then drops to 0 below 10 psi below SP

Rapid Stop

Causes: Low or No Evaporator Water Flow. Low

refrigerant level in evaporator. Incorrect setpoint

value for leaving water temperature.

Manual

Discharge Pressure

High

Discharge pressure > High Condenser Pressure SP

Rapid Stop

Causes: Low or No Condenser Water Flow

Manual

Compressor Starting -

Vanes/Interlock Open

Compressor state = PRELUBE for 30 sec after Prelube

timer expires

Rapid Stop

Manual

Low Oil Delta Pressure

(Comp State=PRELUBE, RUN, UNLOAD, or

POSTLUBE) & Net Oil Press < Low Net Oil Press SP

Rapid Stop

Manual

Low Oil Feed

Temperature

(Comp State=RUN or UNLOAD) & Oil Feed temp <

(Evap Saturated Ref. Temp + Low Oil Delta Temp SP)

for > 1 min

Rapid Stop

Manual

High Oil Feed

Temperature

Temp > High Oil Feed Temperature SP

Rapid Stop

Manual

Low Motor Current

%RLA > Motor Current Threshold SP with Compressor

ON for 30 sec

Rapid Stop

Manual

Discharge Temperature

High

Temp > High Discharge Temp - Load SP

Rapid Stop

Causes: Low or No Condenser Water Flow

Manual

Mechanical High

Pressure

Digital Input = High Pressure

Rapid Stop

Manual

Motor Stator

Temperature High

Digital Input = High Temperature

Rapid Stop

Rotor and/or stator cooling circuit fault

Causes: Motor stator cooling solenoid not open,

rotor cooling stepper motor not functioning

correctly, motor rotor superheat or gain setpoints

incorrect (contact factory)

Manual

Surge Temp High

/ Surge Detected -

Running

Surge Temp > Surge Temp SP

Rapid Stop

Surge Temperature = the suction temperature

minus the leaving chilled water temperature.

Manual

Surge Temp Slope

High / Surge Detected

- Starting

Surge Temp Slope > Surge High Slope SP

Rapid Stop/No Start

Manual

No Starter Transition

Starter Transition Digital Input = No Transition AND

Compressor ON for > 15 seconds

Rapid Stop/No Start

Manual

No Compressor Stop

%RLA > Motor Current Threshold SP with Compressor

OFF for 30 sec

Unit asked to stop but

current still detected

Auto

Starter Fault

Starter Fault Digital Input = Fault AND Compressor

State = START, PRELUBE, RUN, or UNLOAD

Rapid Stop

Manual

Low Oil Pressure Start

Compressor State = START for 30 sec

Rapid Stop/No Start

Manual

Evaporator Water Flow

Loss

Evaporator Flow DI = No Flow for > Evap Flow Loss

Delay SP

OR

(No Flow

AND

shutdown due to low

evaporator pressure

OR

bearing fault) with compressor

running. (Alarm is masked during power fail — timer

restarts after power returns)

Rapid Stop

Causes: Loss of evaporator flow, evaporator

pump off, evaporator head gasket leaking or

missing, sensor wiring fault, evaporator flow

sensor failure

Manual

Condenser Water Flow

Loss

Condenser Flow DI = No Flow for > Cond Flow Loss

Delay SP

OR

(No Flow

AND

shutdown due to high

Cond pressure

OR

bearing fault) with compressor

running. (Alarm is masked during power fail — timer

restarts after power returns)

Rapid Stop

Causes: Loss of condenser flow, condenser

pump off, condenser head gasket leaking or

missing, sensor wiring fault, condenser flow

sensor failure

Manual

Leaving Evaporator

Water Temperature

Sensor Fault

Sensor shorted or open

Rapid Stop

Chilled Water Flow Switch Open

Manual

Evaporator Pressure

Sensor Fault

Sensor shorted or open

Rapid Stop/No Start

Check for loose wires or failed sensor

Manual

Condenser Pressure

Sensor Fault

Sensor shorted or open

Rapid Stop/No Start

Check for loose wires or failed sensor

Manual

Suction Temp Sensor

Fault

Sensor shorted or open

Rapid Stop/No Start

Check for loose wires or failed sensor

Manual

Discharge Temp

Sensor Fault

Sensor shorted or open

Rapid Stop/No Start

Check for loose wires or failed sensor

Manual

Oil Feed Temp Sensor

Fault

Sensor shorted or open

Rapid Stop/No Start

Check for loose wires or failed sensor

Manual

Oil Sump Temp Sensor

Fault

Sensor shorted or open

Rapid Stop/No Start

Check for loose wires or failed sensor

Manual

Oil Feed Pressure

Sensor Fault

Sensor shorted or open

Rapid Stop/No Start

Check for loose wires or failed sensor

Manual

Oil Sump Pressure

Sensor Fault

Sensor shorted or open

Rapid Stop/No Start

Check for loose wires or failed sensor

Manual

Evaporator Pump #1

Fault

No flow indicated for (5 sec) with Evaporator Pump

#1 ON AND [the other pump is available (per the

evaporator Pump SP) AND has not faulted]

Rapid Stop/No Start

Check for loose wires or failed sensor

Manual

Evaporator Pump #2

Fault

No flow indicated for (5 sec) with Evaporator Pump

#2 ON AND [the other pump is available (per the

evaporator Pump SP) AND has not faulted]

Rapid Stop/No Start

Evaporator flow not detected. Causes: improper

pump wiring

Manual