IOM 1322 • WATER-COOLED SCROLL COMPRESSOR 10 www.DaikinApplied.com

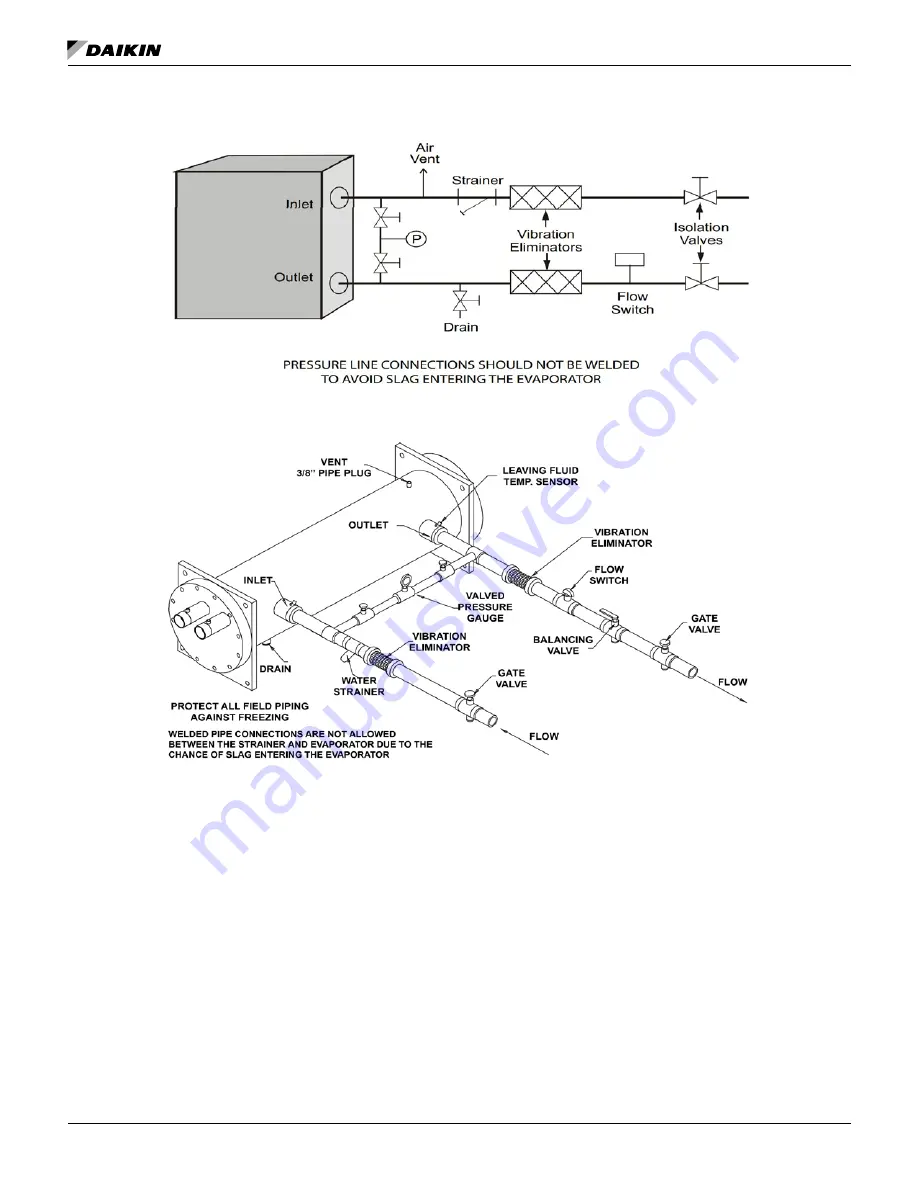

Figure 3: Typical Evaporator Field Water Piping (WGZ030 - WGZ130)

Figure 4: Typical Evaporator Field Water Piping (WGZ150 - WGZ200)

System Water Volume

It is important to have adequate water volume in the system to

provide an opportunity for the chiller to sense a load change,

adjust to the change, and then stabilize. The system water

volume is the total amount of water in the evaporator, air

handling equipment, and associated piping. As the expected

load change becomes more rapid, a greater water volume is

needed. If the water volume is too low, operational problems

can occur including rapid compressor cycling, rapid loading

and unloading of compressors, erratic refrigerant flow in the

chiller, improper motor cooling, shortened equipment life and

other undesirable occurrences.

For normal comfort cooling applications where the cooling load

changes relatively slowly, a minimum system volume of two

to three minutes times the flow rate (GPM) is recommended.

For example, if the design chiller flow rate is 120 gpm, we

recommend a system volume of 240 to 360 gallons.

For process applications where the cooling load can change

rapidly, additional system water volume is needed. A process

example would be the quenching of hot metal objects. The load

would be very stable until the hot metal is dipped into the water

tank. Then, the load would increase drastically.

Since there are many other factors that can influence

performance, systems can successfully operate below these

suggestions. But as the water volume decreases below these

guidelines, the possibility of system instability increases.

Variable Chilled Water Flow

Reducing chilled water flow in proportion to load can reduce

total system power consumption. Certain restrictions apply to

the amount and rate of flow change. The rate of flow change

should be a maximum of 10 percent of the change, per minute.

For example, if the maximum design flow is 200 gpm and it will

be reduced to a flow of 140 gpm, the change in flow is 60 gpm.

Ten percent of 200 gpm equals 20 gpm change per minute, or

a minimum of three minutes to go from maximum.

Water Piping

Summary of Contents for WGZ030DA

Page 4: ......

Page 75: ...Unit Controller Operation www DaikinApplied com 75 IOM 1322 WATER COOLED SCROLL COMPRESSOR ...

Page 76: ...IOM 1322 WATER COOLED SCROLL COMPRESSOR 76 www DaikinApplied com Unit Controller Operation ...

Page 103: ... www DaikinApplied com 103 IOM 1322 WATER COOLED SCROLL COMPRESSOR Maintenance Schedule ...

Page 104: ...IOM 1322 WATER COOLED SCROLL COMPRESSOR 104 www DaikinApplied com Troubleshooting Chart ...

Page 111: ... www DaikinApplied com 111 IOM 1322 WATER COOLED SCROLL COMPRESSOR Limited Product Warranty ...