OMM 1130

-

2

15

When staging down, one compressor on each circuit will be left on until each circuit has only one

compressor running. In other words, the compressor, on either circuit, with the most run-hours will stop

first. The compressor with the most run-hours on the

other

circuit will stop next. One compressor on

each circuit will be running. The third compressor off will be the one, on

either

circuit, with the most

run-hours. The remaining compressor will be the last off. See the following description of pumpdown.

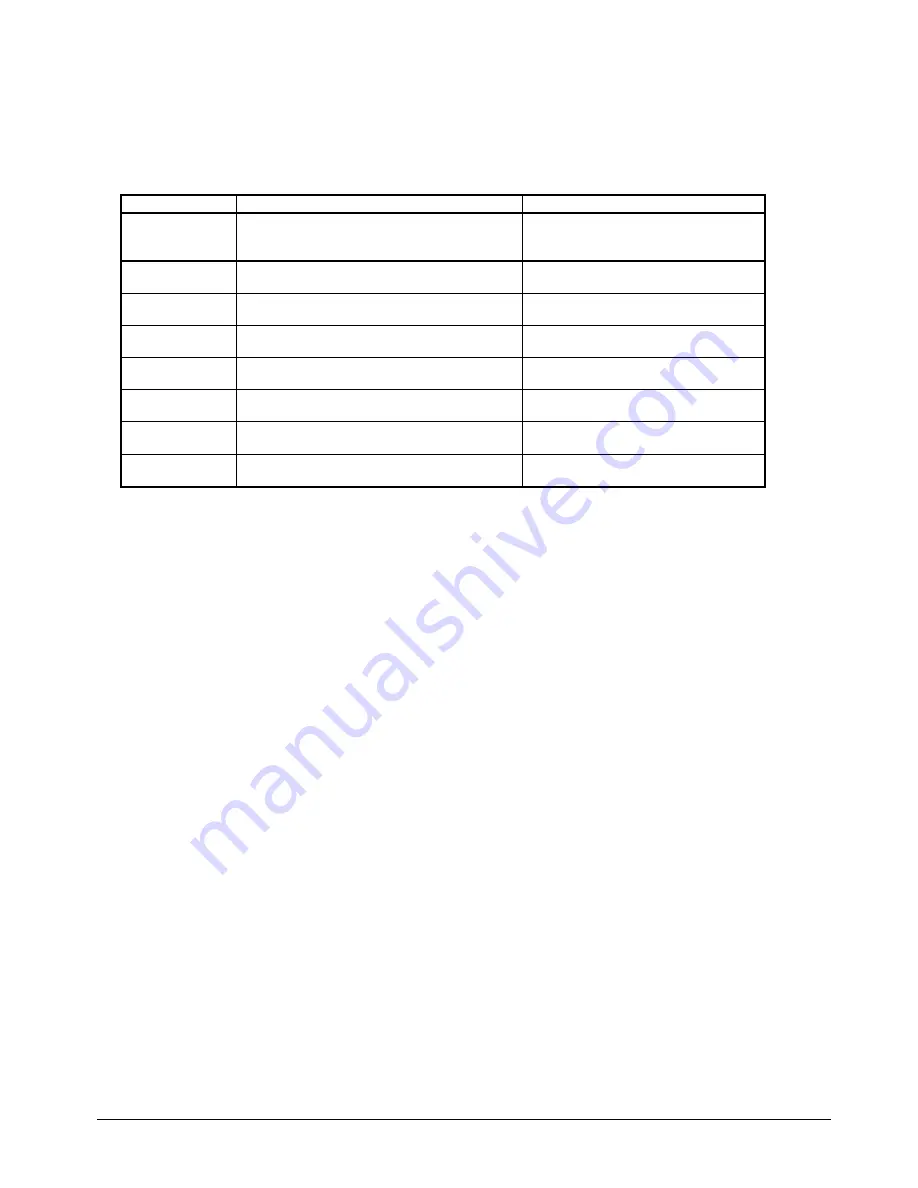

Table 2, Staging in Cool and Glycol Mode

Description

Occurs When:

Action Taken

Stage #1 ON

(See Notes

Below)

Lvg Evap T > Evap LWT SP + (DB/2) +

Startup Delta T

Available compressor with least starts,

ON

Stage #2 ON

After Stage Up Delay times out then, LVG

Evap T > Evap LWT SP + (DB/2)

Available compressor on the other

circuit with least starts, ON

Stage #3 ON

After Stage Up Delay times out, then LVG

Evap T > Evap LWT SP + (DB/2)

Available compressor on either circuit

with least starts, ON

Stage #4 ON

After Stage Up Delay times out then, LVG

Evap T > Evap LWT SP + (DB/2)

Remaining compressor, ON

Stage #4 OFF

After Stage Down Delay times out then, LVG

Evap T < Evap LWT SP – (CB/2)

Compressor with most run hours, OFF

Stage #3 OFF

After Stage Down Delay times out then, LVG

Evap T < Evap LWT SP – (DB/2)

Compressor on the other circuit with

most run hours, OFF

Stage #2 OFF

After Stage Down Delay times out then, LVG

Evap T < Evap LWT SP – (DB/2)

Compressor on either circuit with most

run hours, OFF

Stage #1 OFF

After Stage Down Delay times out then, LVG

Evap T < Evap LWT SP – (DB/2)-StopDelta T

Remaining compressor, OFF

Note 1: DB (Dead Band) = Evap Water Delta T x .3

Manual Compressor Disable Logic

Logic is available that allows the operator to manually enable and disable compressors. When a

compressor is disabled, it is considered unavailable to start in the staging logic. This allows a damaged

compressor to be taken offline while the remaining compressor can still provide some cooling

•

The Compressor Disable set points are found on Compressor Set Points screens three and four.

•

A running compressor cannot be disabled until it has been shutdown.

•

If all of the compressors on a circuit are disabled, then the circuit will be disabled.

•

If both circuits have all of their compressors disabled, then the Unit State will remain Off

Automatic Pumpdown

WGZ units are equipped with single pumpdown control. When the last compressor running on either

circuit is ready to shut off, the liquid line solenoid valve (LLSV) is closed first and the compressor

continues to run until the pumpdown pressure is reached, at which time the compressor shuts off. The

shut off pressure is set at 15 psi below the Low Evaporator pressure Unload setpoint.

When the first compressor on a circuit starts, the LLSV opens simultaneously.

Manual Pumpdown

When the Pumpdown Switch is in the pumpdown position, all compressors except #1 and #2 will shut off.

Then the Liquid Line and Hot Gas Bypass Valves will close. The operating compressor will pump out the

refrigerant. When the Suction Pressure is at 40 psig, the compressors will stop.

Chilled Water and Condenser Water Pumps

The chiller MicroTech II controller can be programmed to start and stop the system chilled water and

condenser water pumps. They may also be controlled by the BAS or manually. Programming directions

and the sequence of operation can be found beginning on page 38.

Cooling Tower Control

The cooling tower fans and/or the tower bypass valve can be controlled by the MicroTech II controller.

This provides a simple and direct method to control the unit’s discharge pressure. Programming

Summary of Contents for WGZ030DW

Page 9: ...OMM 1130 2 9 Figure 6 WGZ030DA WGZ200DA Field Wiring Diagram Remote Condenser...

Page 86: ......

Page 87: ......