IOM 1322-1 • WATER-COOLED SCROLL COMPRESSOR 12 www.DaikinApplied.com

Application Considerations

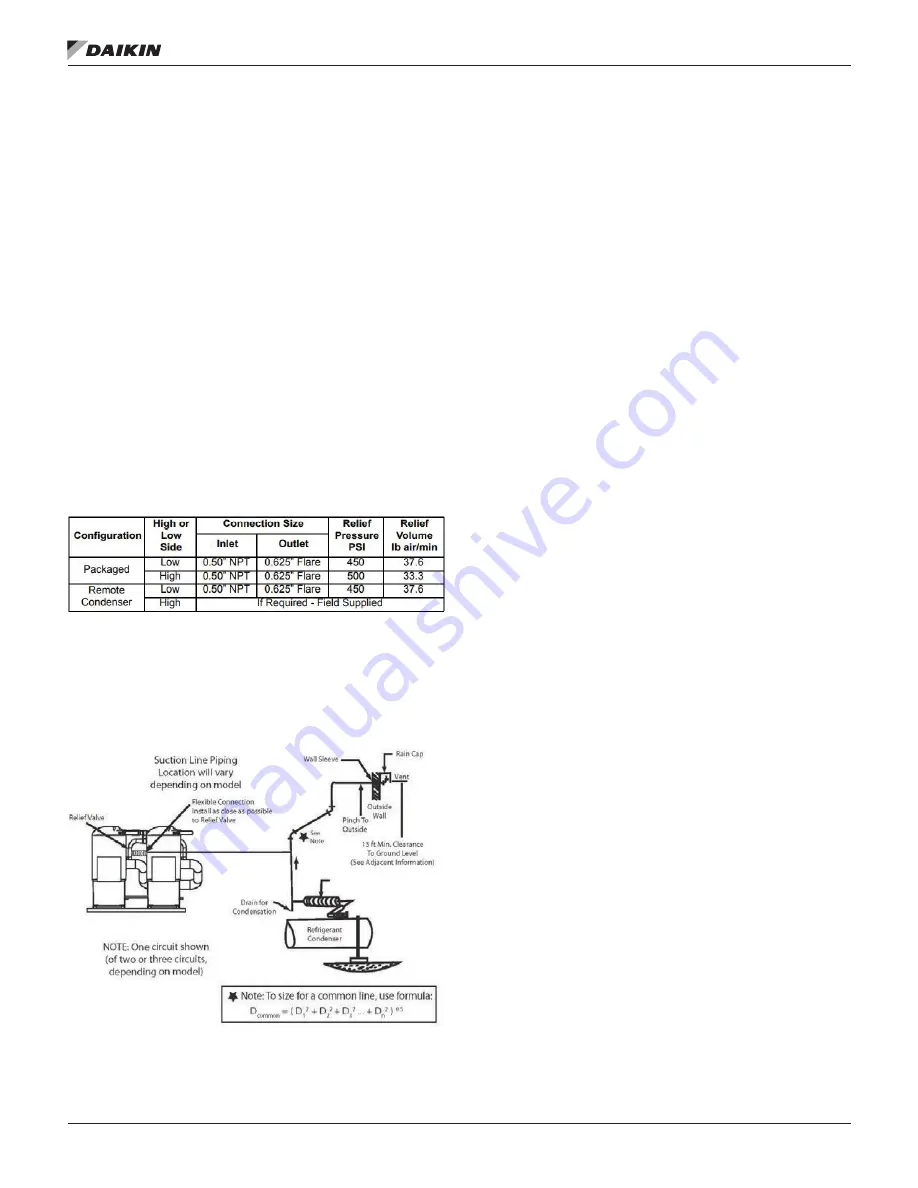

Relief Valve Piping

The ANSI/ASHRAE Standard 15, Safety Standard for

Refrigeration Systems, specifies that pressure relief valves

on vessels containing Group 1 refrigerant (R-410A) “shall

discharge to the atmosphere at a location not less than 15 feet

(4.6 meters) above the adjoining ground level and not less than

20 feet (6.1 meters) from any window, ventilation opening or

exit in any building.” The piping must be provided with a rain

cap at the outside terminating point and with a drain at the

low point on the vent piping to prevent water buildup on the

atmospheric side of the relief valve. Also, a flexible pipe section

should be installed in the line to eliminate any piping stress on

the relief valve(s).

Relief valves are located in the following places depending on

unit configuration:

• Low side with brazed plate evaporator - on the suction

line

• Low side with shell and tube evaporator - on the suction

line

•

High side on packaged unit - on the condenser shell

Table 1: Relief Valve Information

The size of the discharge pipe from the pressure relief valve

should not be less than the size of the pressure relief outlet

(5/8 in. flare). See

for pipe size when combining low

side relief on compressor suction with the condenser relief

valve.

Figure 8: Relief Valve Piping

NOTE:

Fittings should be provided to permit vent piping to be

easily disconnected for inspection or replacement of

the relief valve.

Water Pressure Drop

Water flow rates should be maintained as closely as possible

to job design values. The vessel flow rates must fall between

the minimum and maximum values shown on the appropriate

evaporator and condenser curves. Measure the water pressure

drop through the vessels at field-installed pressure taps and

check the flow rate using the following tables. Do not include

valves or strainers in these readings.

The evaporator flow rates and pressure drops shown on

the following page are for full load design purposes. The

maximum flow rate and pressure drop are based on a 6-degree

temperature drop. Avoid higher flow rates with resulting lower

temperature drops to prevent potential control problems

resulting from very small control bands and limited start up/shut

off temperature changes.

The minimum flow and pressure drop is based on a full load

evaporator temperature drop of 16-degrees.

Summary of Contents for WGZ030DW

Page 4: ......

Page 57: ...Unit Controller Operation www DaikinApplied com 57 IOM 1322 1 WATER COOLED SCROLL COMPRESSOR...

Page 71: ...Unit Maintenance www DaikinApplied com 71 IOM 1322 1 WATER COOLED SCROLL COMPRESSOR...

Page 74: ...IOM 1322 1 WATER COOLED SCROLL COMPRESSOR 74 www DaikinApplied com Troubleshooting Chart...

Page 75: ...Troubleshooting Chart www DaikinApplied com 75 IOM 1322 1 WATER COOLED SCROLL COMPRESSOR...

Page 76: ...IOM 1322 1 WATER COOLED SCROLL COMPRESSOR 76 www DaikinApplied com Troubleshooting Chart...

Page 77: ...Troubleshooting Chart www DaikinApplied com 77 IOM 1322 1 WATER COOLED SCROLL COMPRESSOR...

Page 78: ...IOM 1322 1 WATER COOLED SCROLL COMPRESSOR 78 www DaikinApplied com Troubleshooting Chart...