IOM 1322-1 • WATER-COOLED SCROLL COMPRESSOR 40 www.DaikinApplied.com

Unit Controller

Pull Down Rate

The slope value calculated above will be a negative value as

the water temperature is dropping. For use in some control

functions, the negative slope is converted to a positive value by

multiplying by –1.

Evaporator Saturated Temperature

Evaporator saturated temperature is calculated from the

evaporator pressure for each circuit.

R410A Evaporator Saturated Temperatures

When R410A refrigerant is selected the refrigerant pressure

will be fitted to a curve made up of 24 straight-line segments.

The accuracy of calculated saturated temperatures are less

than +/- 0.5°F when compared to standard look up tables for

R410A.

R134a Evaporator Saturated Temperatures (Templifiers

only)

When R134a refrigerant is selected the refrigerant pressure

will be fitted to a curve made up of 12 straight-line segments.

The accuracy of calculated saturated temperatures is +/-

0.5º F when compared to standard look up tables for R134a

refrigerant.

Condenser Saturated Temperature

Condenser saturated temperature shall be calculated from the

condenser pressure for each circuit.

R410A Evaporator Saturated Temperatures

When R410A refrigerant is selected the refrigerant pressure

will be fitted to a curve made up of 24 straight-line segments.

The accuracy of calculated saturated temperatures are less

than +/- 0.5°F when compared to standard look up tables for

R410A.

R134a Evaporator Saturated Temperatures (Templifiers

only)

When R134a refrigerant is selected the refrigerant pressure

will be fitted to a curve made up of 12 straight-line segments.

The accuracy of calculated saturated temperatures is +/-

0.5º F when compared to standard look up tables for R134a

refrigerant.

Evaporator Approach

The evaporator approach is calculated for each circuit.

For R134a and R410A refrigerant the equation is:

Evaporator Approach = LWT – Evaporator Saturated

Temperature

Suction Superheat

Suction superheat is calculated for each circuit using the

following equation:

Suction superheat = Suction Temperature – Evaporator

Saturated Temperature

Pump Down Pressure

The pressure to which a circuit will pump down is based on the

Low Evaporator Pressure Unload set point. The equation is as

follows:

Pumpdown pressure = Low evap pressure unload – 15 psi

The low limit for the calculated Pumpdown Pressure set point

is 10.0 psi

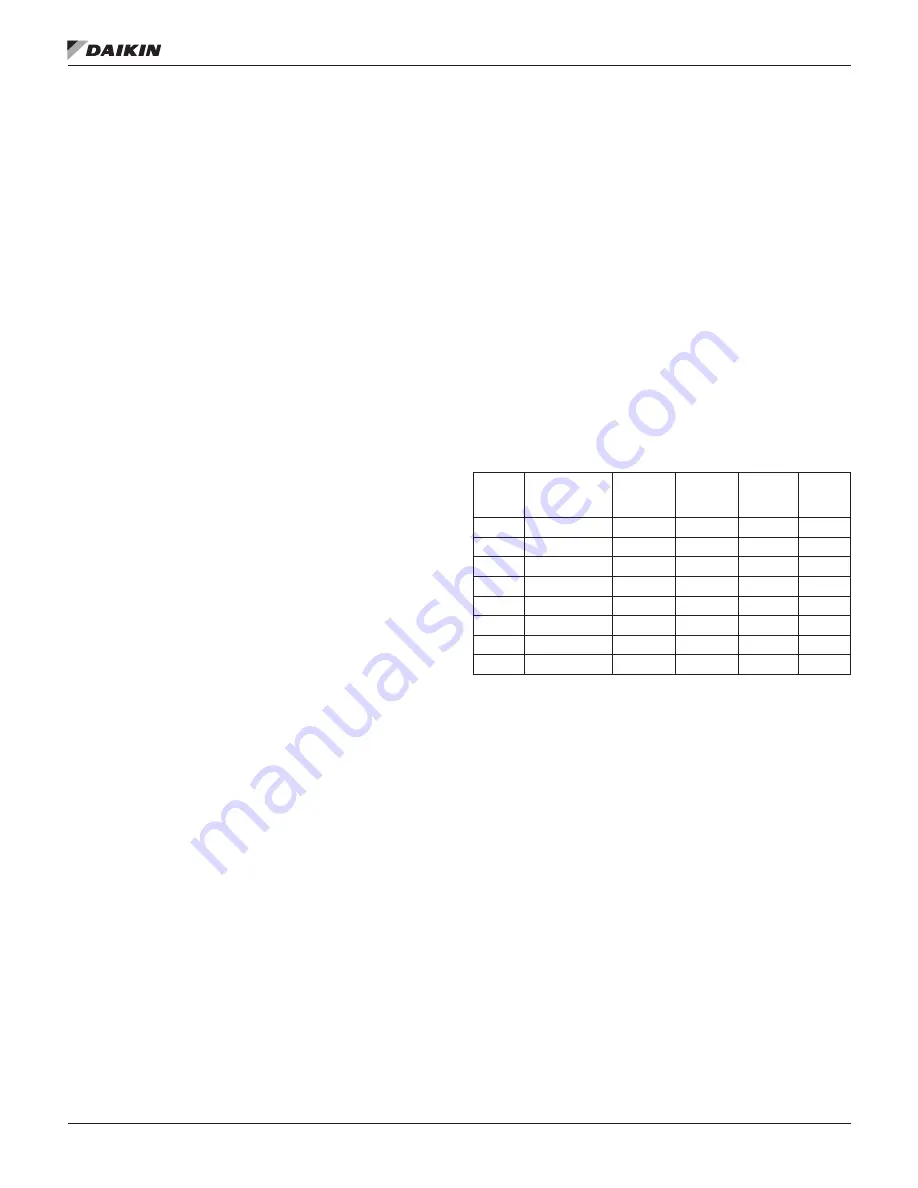

Unit Enable

The Unit Enable Set Point controls enabling and disabling the

unit. The Unit Enable Set Point has options of OFF and ON.

The Unit OFF input, Remote input, keypad entry, and BAS

request can alter this set point. The Control Source Set Point

determines which sources can change the Unit Enable Set

Point with options of SWITCHES, KEYPAD or NETWORK.

Changing the Unit Enable Set Point is accomplished according

to the following table.

NOTE:

An “x” indicates that the value is ignored.

Unit Off

Input

Control Source

Set Point

Remote

Input

Keypad

Entry

BAS

Request

Unit

Enable

OFF

X

X

X

X

OFF

X

SWITCHES

OFF

X

X

OFF

ON

SWITCHES

ON

X

X

ON

ON

KEYPAD

X

OFF

X

OFF

ON

KEYPAD

X

ON

X

ON

ON

NETWORK

X

X

OFF

OFF

ON

NETWORK

OFF

X

X

OFF

ON

NETWORK

ON

X

ON

ON

Unit Mode

The overall operating mode of the chiller is set by the Unit

Mode Set Point with options of COOL, COOL w/Glycol, ICE w/

Glycol, and TEST. This set point can be altered by the keypad,

BAS, and Mode input.

Changes to the Unit Mode Set Point are controlled by two

additional set points.

• Available Modes Set Point: Determines the operational

modes available at any time with options of COOL, COOL

w/Glycol, COOL/ICE w/Glycol, ICE w/Glycol and TEST

• Control Source Set Point: Determines the source that can

change the Unit Mode Set Point with options of KEYPAD,

NETWORK, or SWITCHES.

When the Control source is set to KEYPAD, the Unit Mode

shall stay at its previous setting until changed by the operator.

When the Control source is set to BAS, the most recent BAS

mode request shall go into effect even if it changed while the

Control source was set to KEYPAD or DIGITAL INPUTS.

Changing the Unit Mode Set Point can be accomplished

according to the following table.

NOTE:

An “x” indicates that the value is ignored.

Summary of Contents for WGZ030DW

Page 4: ......

Page 57: ...Unit Controller Operation www DaikinApplied com 57 IOM 1322 1 WATER COOLED SCROLL COMPRESSOR...

Page 71: ...Unit Maintenance www DaikinApplied com 71 IOM 1322 1 WATER COOLED SCROLL COMPRESSOR...

Page 74: ...IOM 1322 1 WATER COOLED SCROLL COMPRESSOR 74 www DaikinApplied com Troubleshooting Chart...

Page 75: ...Troubleshooting Chart www DaikinApplied com 75 IOM 1322 1 WATER COOLED SCROLL COMPRESSOR...

Page 76: ...IOM 1322 1 WATER COOLED SCROLL COMPRESSOR 76 www DaikinApplied com Troubleshooting Chart...

Page 77: ...Troubleshooting Chart www DaikinApplied com 77 IOM 1322 1 WATER COOLED SCROLL COMPRESSOR...

Page 78: ...IOM 1322 1 WATER COOLED SCROLL COMPRESSOR 78 www DaikinApplied com Troubleshooting Chart...