IM 1044-2

Centrifugal Chillers

23

Vent piping is sized for only one valve of the set since only one can be in operation at a time. In no case would a

combination of evaporator and condenser sizes require more refrigerant than the pumpdown capacity of the

condenser. Condenser pumpdown capacities are based on the current ANSI/ASHRAE Standard 15 that

recommends 90% full at 90°F (32

°

C). To convert values to the older AHRI standard, multiply pumpdown

capacity by 0.888.

Sizing Vent Piping (ASHRAE Method)

Relief valve pipe sizing is based on the discharge capacity for the given evaporator or condenser and the length of

piping to be run. Discharge capacity for R-134a vessels is calculated using a complicated equation that accounts

for equivalent length of pipe, valve capacity, Moody friction factor, pipe ID, outlet pressure and back pressure.

The formula, and tables derived from it, is contained in ASHRAE Standard 15.

Daikin

centrifugal units have relief valve settings of 180 psi, 200 psi, and 225 psi, and resultant valve

discharge capacities of 68.5 # air/min, 75.5 # air/min, and 84.4 # air/min respectively.

Using the ASHRAE formula and basing calculations on the 225 psi design yields a conservative pipe size, which

is summarized in Table 12. The table gives the pipe size required

per relief valve

. When valves are piped together,

the common piping must follow the rules set out in the following paragraph on common piping.

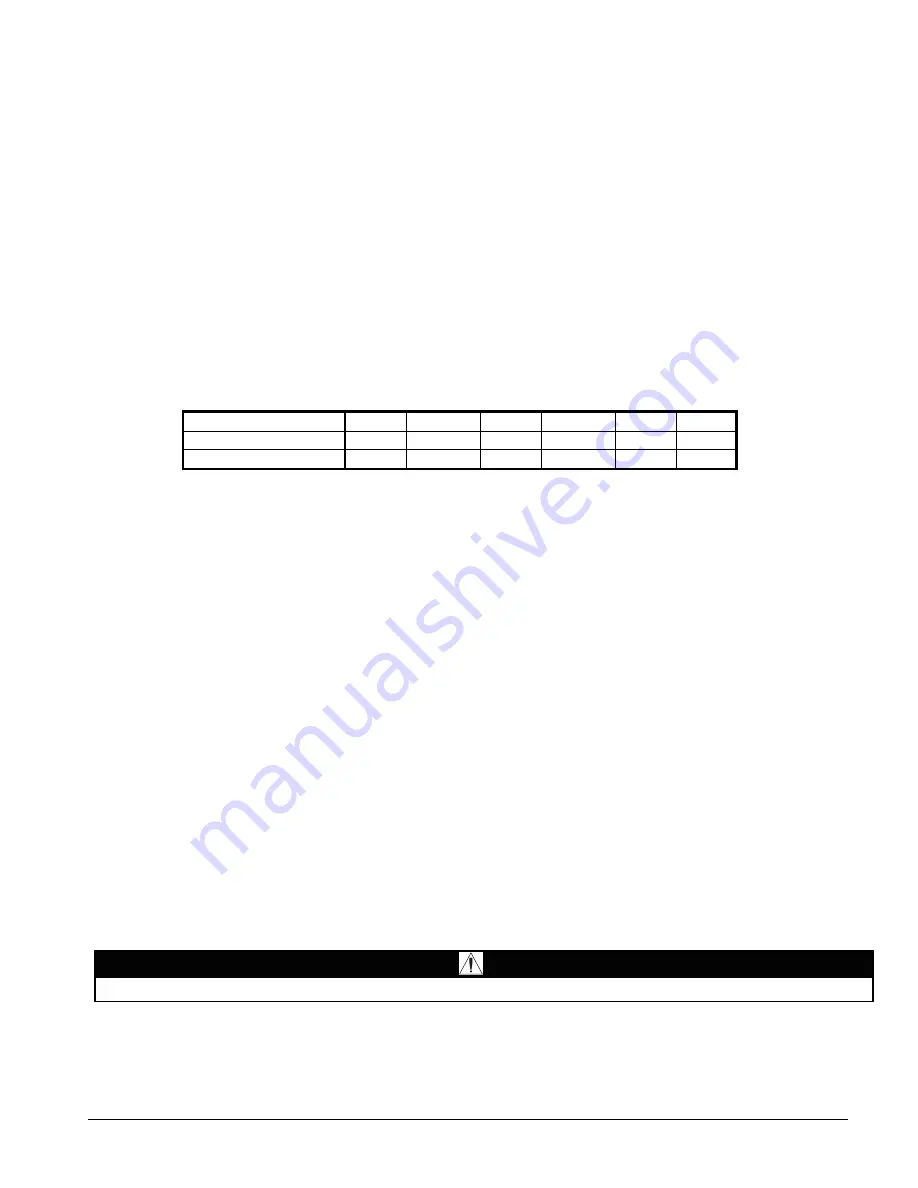

Table 12, Relief Valve Piping Sizes

Equivalent length (ft)

2.2

18.5

105.8

296.7

973.6

4117.4

Pipe Size inch (NPT)

1 1/4

1 1/2

2

2 1/2

3

4

Moody Factor

0.0209

0.0202

0.0190

0.0182

0.0173

0.0163

NOTE: A 1-inch pipe is too small for the flow from the valves. A pipe increaser must always be installed at the valve outlet.

Common Piping

According to ASHRAE Standard 15, the pipe size cannot be less than the relief valve outlet size. The discharge

from more than one relief valve can be run into a common header, the area of which cannot be less than the sum

of the areas of the connected pipes. For further details, refer to ASHRAE Standard 15. The common header can

be calculated by the formula:

DCommon

D

D

Dn

=

+

1

2

2

2

2

0 5

....

.

The above information is a guide only. Consult local codes and/or latest version of ASHRAE Standard 15 for

sizing data.

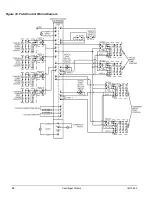

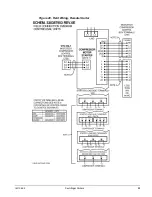

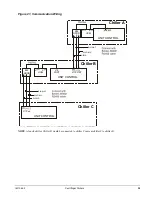

Electrical

Wiring, fuse and wire size must be in accordance with the National Electric Code (NEC). Standard NEMA

motor starters require modification to meet

Daikin

specifications. Refer to

Daikin

Specification R359999

Rev 29 available from the local

Daikin

sales representative.

Important

: Voltage unbalance not to exceed 2% with a resultant current unbalance of 6 to 10 times the voltage

unbalance per NEMA MG-1 Standard. This is an important restriction that must be adhered to.

Power Wiring

Power Factor Correction Capacitors

Do not use power factor correction capacitors with centrifugal chillers with a compressor VFD. Doing so can

cause harmful electrical resonance in the system. Correction capacitors are not necessary since VFDs inherently

maintain high power factors

WARNING

Qualified and licensed electricians must perform wiring. Shock hazard exists.

Power wiring to compressors must be in proper phase sequence. Motor rotation is set up for clockwise rotation

facing the lead end with phase sequence of 1-2-3. Care must be taken that the proper phase sequence is carried

through the starter to compressor. With the phase sequence of 1-2-3 and L1 connected to T1 and T6, L2

connected to T2 and T4, and L3 connected to T3 and T5, rotation is proper. See diagram in terminal box cover.