34

Centrifugal Chillers

IM 1044-2

Multiple Chiller Setup

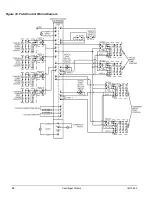

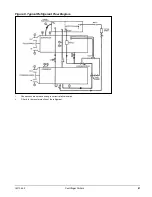

Single compressor chillers WSC and dual compressor chillers WDC and WCC have their main control components

factory wired to an internal pLAN network so that the components can communicate with each other, within the

chiller itself. On multi-chiller applications, up to four chillers, either single, or dual compressor, can be

interconnected by this internal pLAN. All that is required is simple field RS485 interconnecting wiring, the

addition of accessory communication isolation board(s) 485OPDR (

Daikin

P/N 330276202), and some MicroTech

II control settings (see special WCC instructions at the end of this section). The 485OPDR isolation board can be

purchased with the unit or separately, during or after chiller installation. The number of boards required equals the

number of chillers minus one.

Note:

pLAN multiple chiller interconnection is designed for parallel chiller installations with the leaving water

sensors in their normal location in the outlet nozzle.

For two units in series operation, the leaving chilled water sensors must be moved far enough downstream from the

last chiller to insure reading a thoroughly mixed water temperature. Passing through one or two elbows will usually

suffice. Series chillers are normally single pass resulting in undesirable temperature stratification at the outlet nozzle

Interconnectability

Centrifugal models WSC and WDC of various vintages with MicroTech II controllers can be interconnected but all

must be loaded with the most recent control software.

Responsibilities

Unless otherwise stated in the contract documents, the interconnecting MicroTech II pLAN RS485 multiple chiller

wiring between chillers is the responsibility of the installing contractor and should be completed prior to startup.

The

Daikin

startup technician is responsible is to check the wiring and make the appropriate control changes.

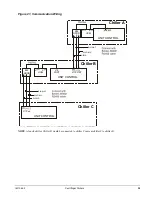

pLAN Wiring

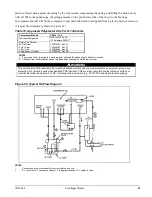

Connect chillers together (pLAN, RS485 wiring) as shown in Figure 21 on the following page. The first chiller in

the connection can be designated as Chiller A. The isolation board is attached to the DIN rail adjacent to the Chiller

A unit controller. The isolation board has a pigtail that is plugged into J10 on the controller. Most chillers will

already have a universal communication module (UCM) that connects the controller to the touchscreen already

plugged onto J10. If this is the case, plug the isolation module pigtail into the empty RJ11 pLAN port on the UCM.

This is equivalent to plugging into the unit controller directly.

Next, interconnecting wiring is needed between Chiller A and Chiller B.

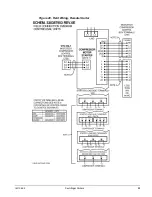

Two Chillers

: If only two chillers are to be connected, Belden M9841 (RS 485 Spec Cable) is wired from the

485OPDR isolation board (terminals A, B, and C) on Chiller A to the J11 port on the unit controller of Chiller B. At

J11, the shield connects to GND, the blue/white wire to the (+) connection, and the white/blue to the (-) connection.

Note that Chiller B does not have an isolation board. The last chiller (B in this case) to be connected does not need

an isolation board.

Three or Four Chillers

: If three or more chillers are to be connected, the interconnecting wiring is still made to

Chiller B’s J11 port. The second chiller (Chiller B) must have a 485OPDR isolator board that will be plugged into

Chiller B’s UCM pLAN port. Chiller B will look like Chiller A.

The wiring from Chiller B to Chiller C will be the same as A to

B. That is, Belden cable connects from A, B, and C

on B’s 485OPDR board to chiller C’s L11 port. Chiller C has no 485OPDR isolation board.

The procedure is repeated to the fourth chiller if four chillers are interconnected.

Sequencing

The

Daikin

technician can set up different strategies for starting and stopping networked compressors, chillers, and

pumps depending on site requirements.