36

Centrifugal Chillers

IM 1044-2

MicroTech II Operator Interface Touch Screen (OITS) Settings

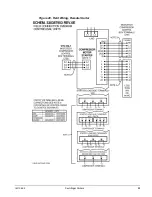

Settings for any type of linked multiple compressor operation must be made to the MicroTech II controller.

Settings on a dual compressor unit are made in the factory prior to shipment, but must be verified in the field

before startup. Settings for multiple chiller installations are set in the field on the Operator Interface Touch Screen

as follows:

Maximum Compressors ON – SETPOINTS - MODES screen, Selection #10 ‘= 2 for a dual, 4 for 2 duals, 3 for

three separate, single compressor chillers, etc. If all compressors in the system are to be available as normal

running compressors, then the value entered in #10 should equal the total number of compressors. If any

compressors are for standby and not operated in normal rotation, they should not be included in the compressor

count in Selection #10. The Max Comp ON setting can be made in only one touchscreen, the system will observe

the highest number set on all chillers-it is a global setting.

Sequence and Staging – SETPOINTS - MODES screen, Selection #12 & #14; #11 & #13. Sequence sets the

sequence in which compressors will start. Setting one or more compressors to “1” evokes the automatic lead/lag

feature and is the normal setting. The compressor with least starts will start first and the compressor with

maximum hours will stop first, and so on. Units with higher numbers will stage on in sequence.

The Modes setpoints will do several different types of operation (Normal, Efficiency, Standby, etc.) as described

in the operating manual.

The same Modes setting must be replicated on each chiller in the system.

Nominal Capacity – SETPOINTS - MOTOR screen, Selection #14. The setting is the compressor design tons.

Compressors on dual units are always of equal capacity.

WCC Settings

Since the WCC is essentially two chillers combined into one counterflow, single pass, dual-circuit chiller, the

compressor on the downstream circuit (leaving chilled water) must always be designated as the Stage 1

compressor-first on, last off.

Operating Sequence

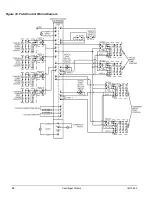

For multiple-chiller, parallel operation, the MicroTech II controllers are tied together by a pLAN network and

stage and control compressor loading among the chillers. Each compressor, single or dual compressor chiller, will

stage on or off depending on the sequence number programmed into it. For example, if all are set to “1”, the

automatic lead/lag will be in effect.

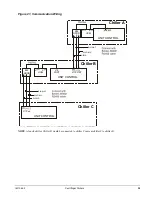

When chiller #1 is fully loaded, the leaving chilled water temperature will rise slightly. When the Delta-T above

setpoint reaches the Staging Delta-T, the next chiller scheduled to start will receive a start signal and start its

pumps if they are set up to be controlled by the Microtech controller. This procedure is repeated until all chillers

are running. The compressors will load-balance themselves.

If any of the chillers in the group are dual compressor, they will stage and load according to the staging

instructions.

See

OM 1153

(current revision) for a complete description of the various staging sequences available.