42

Centrifugal Chillers

IM 1044-2

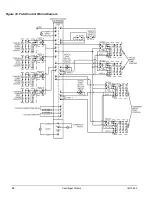

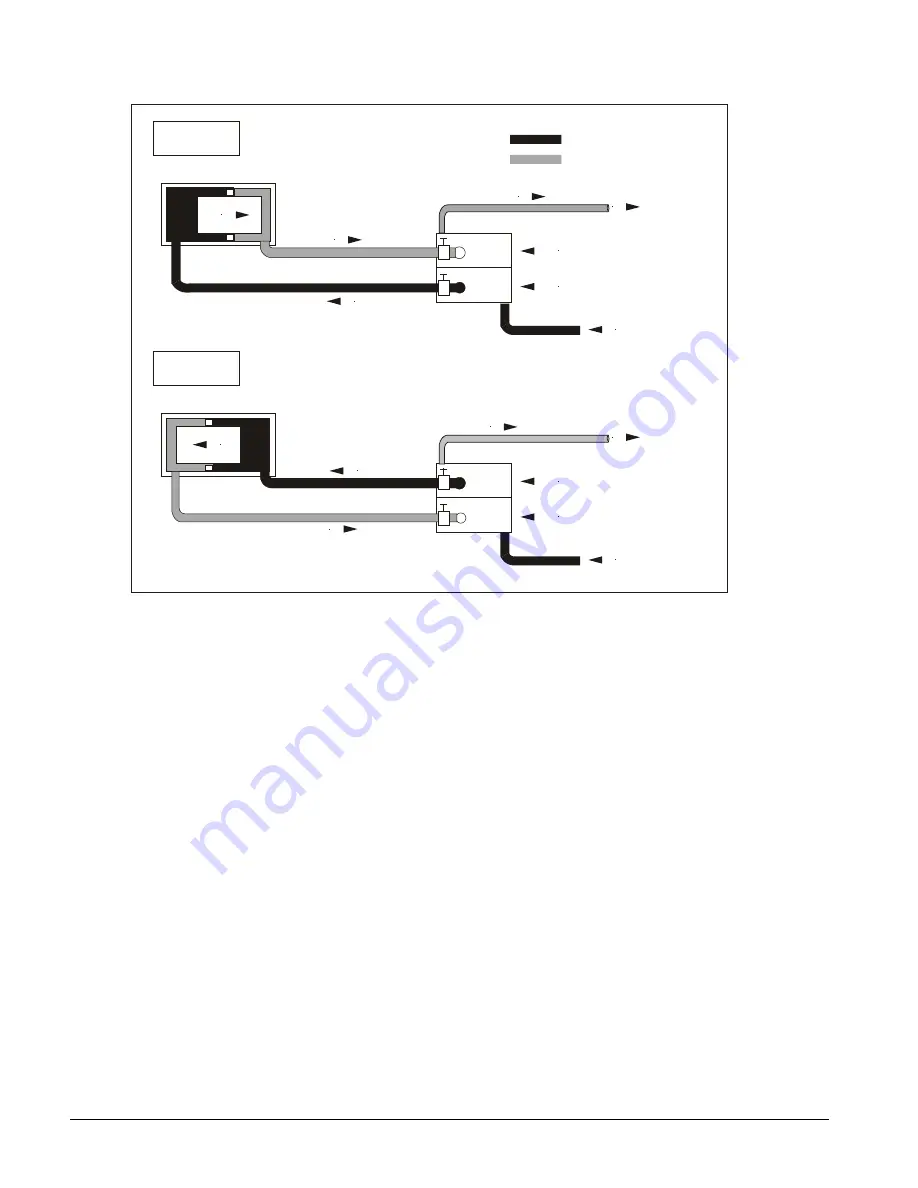

Figure 28, Vane Control Solenoid Operation, Continued

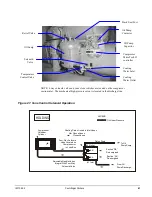

Surge and Stall

Stall and surge are a characteristic of all centrifugal compressors. These conditions occur when low load

combines with high compressor lift. In a stall, discharge gas has insufficient velocity leaving the impeller to reach

the volute and just “sits” or stalls in the diffuser section. The compressor sound level goes way down due to no

flow and the impeller starts to heat up. In surge, the heated discharge gas alternately flows back through the

impeller and then reverses to the volute about every two seconds. Extreme noise and vibration occur. The

compressor is equipped with a temperature sensor that shuts it off if these conditions occur.

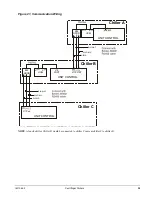

Lubrication System

The lubrication system provides lubrication and heat removal for compressor bearings and internal parts. In

addition, the system provides lubricant under pressure to hydraulically operate the unloading piston for

positioning the inlet guide vanes for capacity control. WDC, dual compressor chillers, have completely

independent lubrication systems for each compressor.

Only the recommended lubricant, as shown in Table 15, can be used for proper operation of the hydraulic system

and bearing lubrication system. Each unit is factory-charged with the correct amount of the recommended

lubricant. Under normal operation, no additional lubricant is needed. Lubricant must be visible in the sump sight

glass at all times.

Compressor sizes, CE063 through CE126, utilize a separate lubricant pump located in the sump. The sump

includes the pump, motor, heater and lubricant/vapor separator system. The lubricant is pumped through the

external oil cooler and then to the oil filter located inside the compressor housing. WSC/WDC/WCC 063-126

units, single or dual compressor, all utilize a water-cooled oil cooler for each compressor.

The oil coolers maintain the proper oil temperature under normal operating conditions. The coolant flow control

valve maintains 95°F to 105°F (35°C to 41°C). Lubrication protection for coast down in the event of a power

failure is accomplished by a spring-loaded piston in models CE063 through 100. When the oil pump is started, the

Drain From Piston

#3 Outlet

SB

SA

#1 Intlet

LEGEND

Oil Under Pressure

To Oil

Pump Sump

Section “SB”

Energized

Section “SA”

De-energized

From Oil

Pump Discharge

OPENING

Oil Sump Pressure

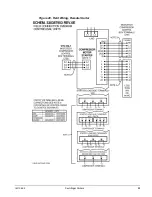

Drain From Piston

#3 Outlet

SB

SA

#1 Intlet

To Oil

Pump Sump

Section “SB”

De-energized

Section “SA”

Energized

From Oil

Pump Discharge

CLOSING

Piston Drain