46

Centrifugal Chillers

IM 1044-2

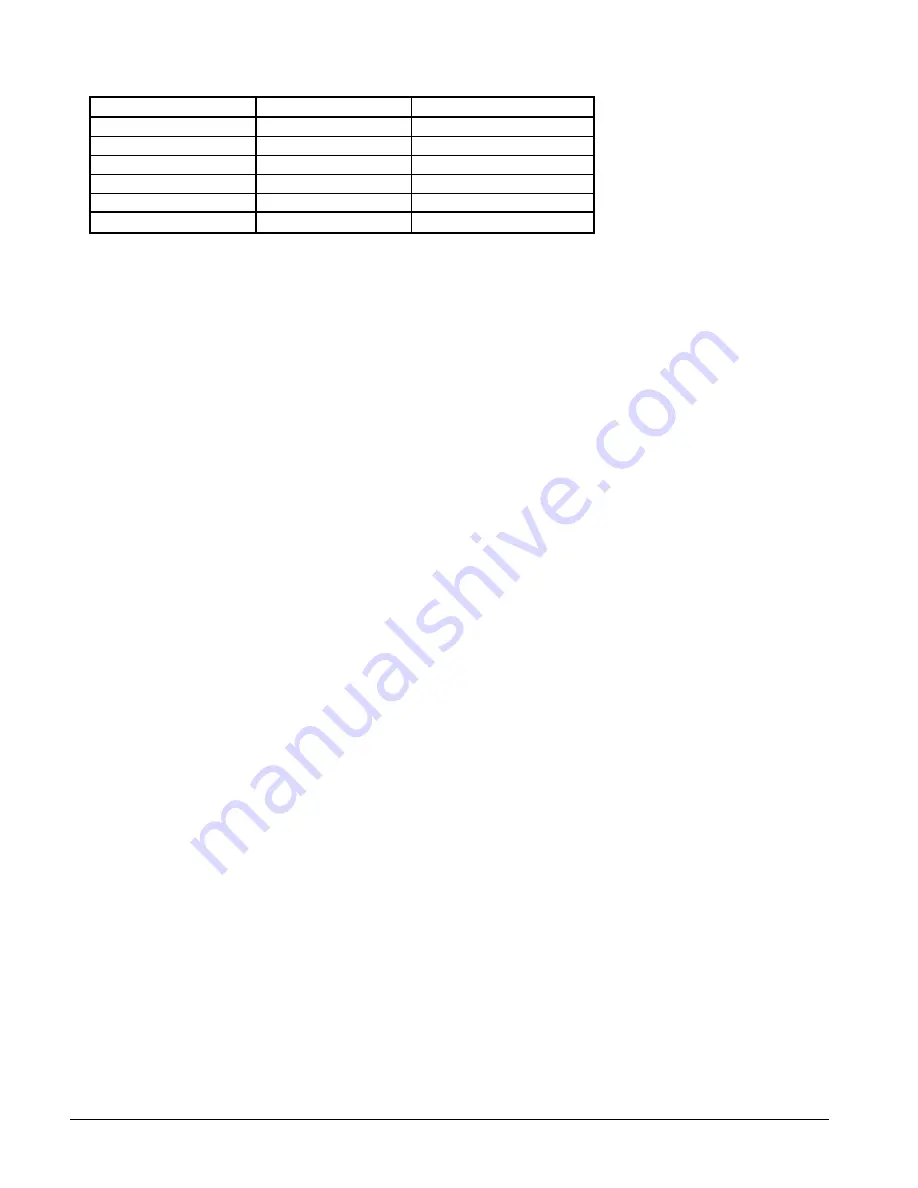

Table 16, Metal and Moisture Limits

Element

Upper Limit (PPM)

Action

Aluminum

50

1

Copper

100

1

Iron

100

1

Moisture

400

2

Silica

50

1

Total Acid Number (TAN)

0.19

3

Key to Action

1)

Re-sample after 500 hours of unit operation.

a) If content increases less than 10%, change oil and oil filter and re-sample at normal interval (usually

annual).

b) If content increases between 11% and 24%, change oil and oil filter and re-sample after an additional

500 hours of operation.

c) If content increases more than 25%, inspect compressor for cause.

2)

Re-sample after 500 hours of unit operation.

a) If content increases less than 10%, change filter-drier and re-sample at normal interval (usually

annual).

b) If content increases between 11% and 24%, change filter-drier and re-sample after an additional 500

hours of operation.

c) If content increases more than 25%, monitor for a water leak.

3)

If TAN is less than 0.10, system is safe as far as acid is concerned.

a) For TAN between 0.10 and 0.19, re-sample after 1000 hours of operation.

b) For TAN above 0.19, change oil, oil filter, and filter-drier and resample at normal interval

Changing Oil Filters

Daikin

chillers are at positive pressure at all times and do not leak contaminated moist air into the

refrigerant circuit, thereby eliminating the need for annual oil changes. An annual laboratory oil check is

recommended to check overall compressor condition.

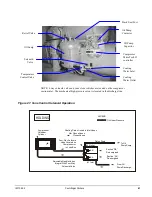

The oil filter can be changed by simply isolating the filter cavities. Close the oil discharge line service valve at the

oil pump (at the filter on CE126). Remove the filter cover; some foaming can occur but the check valve should

limit leakage from other compressor cavities. Remove the filter, replace with new element, and replace filter cover

using a new gasket. Reopen the valve in the pump discharge line and purge air from the oil filter cavity.

When machine is operated again, the oil level must be checked to determine if oil needs to be added to maintain

the proper operating level.

Refrigerant Cycle

Maintenance of the refrigerant cycle includes maintaining a log of the operating conditions, and checking that the

unit has the proper oil and refrigerant charge.

At every inspection, the oil, suction, and discharge pressures should be noted and recorded, as well as condenser

and chiller water temperatures.

The suction line temperature at the compressor should be taken at least once a month. Subtracting the saturated

temperature equivalent of the suction pressure from this will give the suction superheat. Extreme changes in

subcooling and/or superheat over a period of time will indicate losses of refrigerant or possible deterioration or

malfunction of the expansion valves. Proper superheat setting is 0 to 1 degree F (0.5 degree C) at full load. Such a

small temperature difference can be difficult to measure accurately. Another method is to measure the compressor

discharge superheat, the difference between the actual discharge temperature and the saturated discharge

temperature. The discharge superheat should be between 14 and 16 degrees F (8 to 9 degrees C) at full load. The

liquid injection must be deactivated (by closing the valve in the feed line) when taking the discharge temperature.

The superheat will increase linearly to 55 degrees F (30 degrees C) at 10% load. The MicroTech II interface panel

can display all superheat and subcooling temperatures.