SINGLE SCREW CHILLERS IMM

44

Engineered for Flexibility and Performance

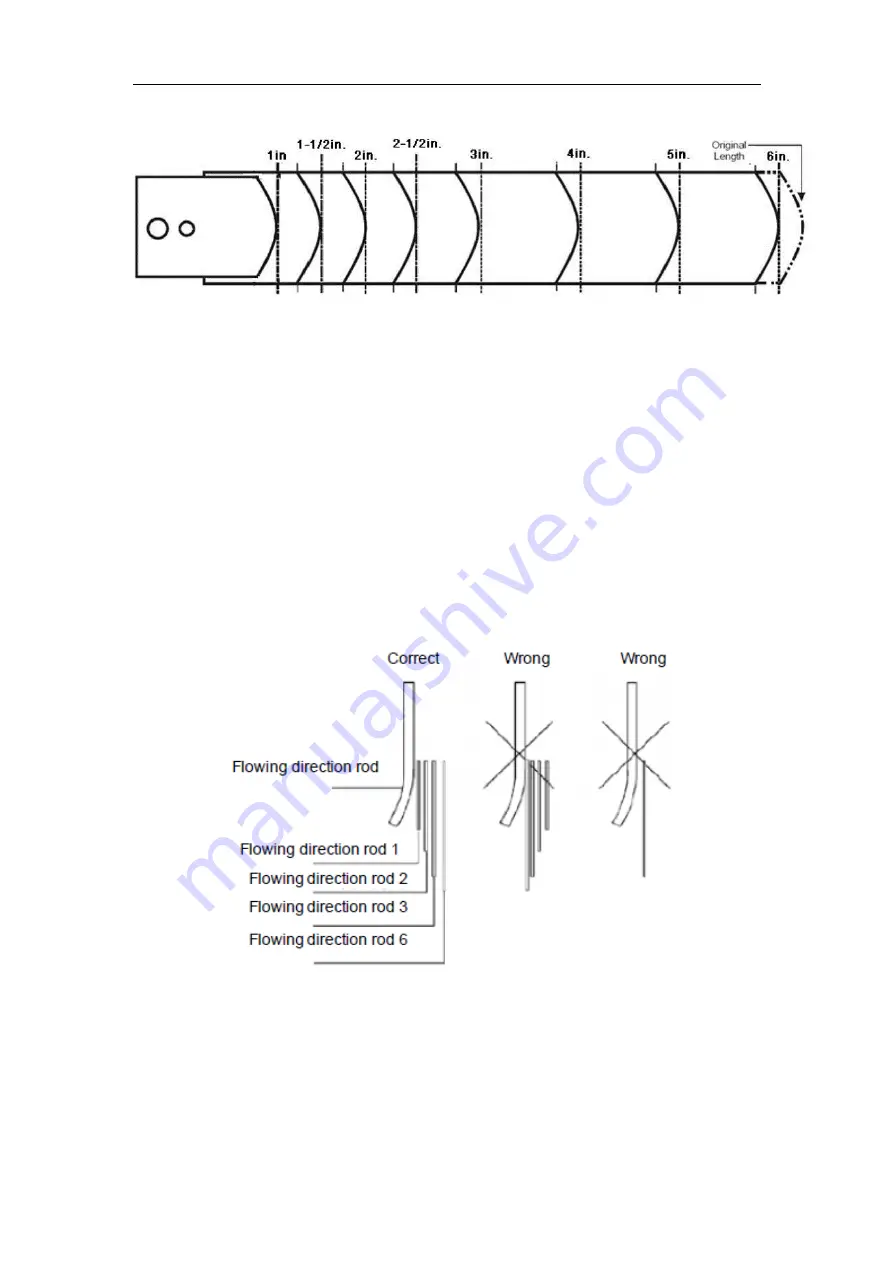

3. Flowing direction sheet

Fig.3 Trimming Template Sketch Map of Flowing Direction Sheet

Fig.3 is a trimming template sketch map and please refers to the trimming template of flow

switch during the practical operation.

User can install the removable flowing direction sheet 1, 2, 3 and 6 of flow switches

allocated by the factory according to actual needs. If flowing direction sheets of other

dimensions are needed, trim the flowing direction sheet based on the template and match

its arc shape with the pipeline. For instance: as shown in Fig.4, flowing direction sheet 1, 2

and 3 can be installed for the 3’’ pipeline. Flowing direction sheet 2 shall be trimmed to the

proper length as per the template when 1-1/2’’ pipeline is used. In addition to installing

flowing direction sheet 1, 2 and 3, lowing direction sheet 6 shall be trimmed to the proper

size according to the

Inside Diameter Flowing Direction Sheet Template of Corresponding

Pipeline

and used for the installation of 4’’, 5’’ and 6’’ pipelines. Flowing direction sheet 1,

2, 3, and 6 shall be installed on the 8’’ pipeline. The correct installation positions are

shown in the Fig.4.

Notes: The flowing direction sheet shall not contact with the pipeline and any throttling

device in the pipe so that the switch can induce the flow rate variation.

Fig.4

4. Installation Requirements

4.1 The flow switches must be installed on the straight pipeline with at least straight

stroke of 5 times of the pipe diameter on both sides (as shown in Fig.5). The

connecting terminals shall be installed on the position available for connection during

the installation of switches.