1.

Ensure the fuel tank is between 50 and 75 per-

cent full.

2.

Check the fuel tank pressure gauge (

, Item

8) to ensure that pressure is within the normal

range of 120 to 150 psi (827 to 1034 kPa).

3.

Inspect the fuel tank for signs of frost spots or

outer surface sweating. Frosting or condensation

on the outer surface of the fuel tank may indicate

a loss of vacuum.

4.

Check for a large variance in temperatures be-

tween the fuel tank and the fuel tank shroud. A

large variance in temperatures between the fuel

tank and the shroud may indicate a loss of

vacuum.

5.

Operate the vehicle for ten minutes. Shut down

the engine, apply the parking brakes, and note

the time.

6.

Wait fifteen minutes after shutting down the en-

gine, then record the fuel tank pressure and note

the time.

7.

Allow the vehicle to stand for at least eight

hours, then record the fuel tank pressure again.

8.

Use

to determine whether the pressure

increase is within an acceptable range.

06/29/2009

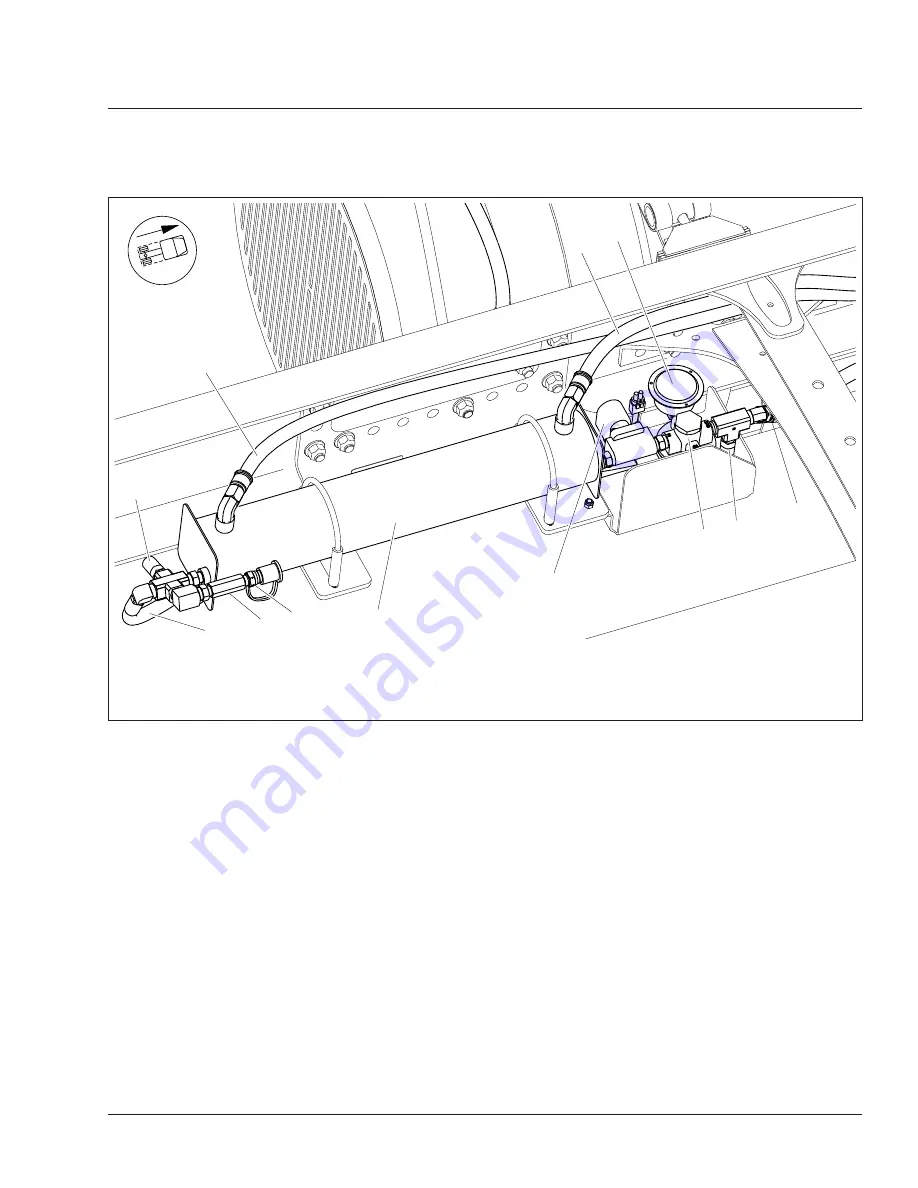

f470536

2

5

6

7

8

9

10

11

12

1

3

4

1.

Pressure Relief Device

2.

Fuel Inlet Line

3.

Check Valve

4.

CNG Quick-Connect Port

5.

Coolant Inlet Line

6.

Vaporizer

7.

Fuel Shutoff Solenoid Valve

8.

Coolant Outlet Line

9.

Pressure Gauge

10. Overpressure Regulator

11. Pressure Relief Valve

12. Fuel Outlet Line

Fig. 6, LNG Vaporizer Assembly

Fuel

47

Business Class M2 Maintenance Manual, August 2015

47/7

Property of American Airlines