13

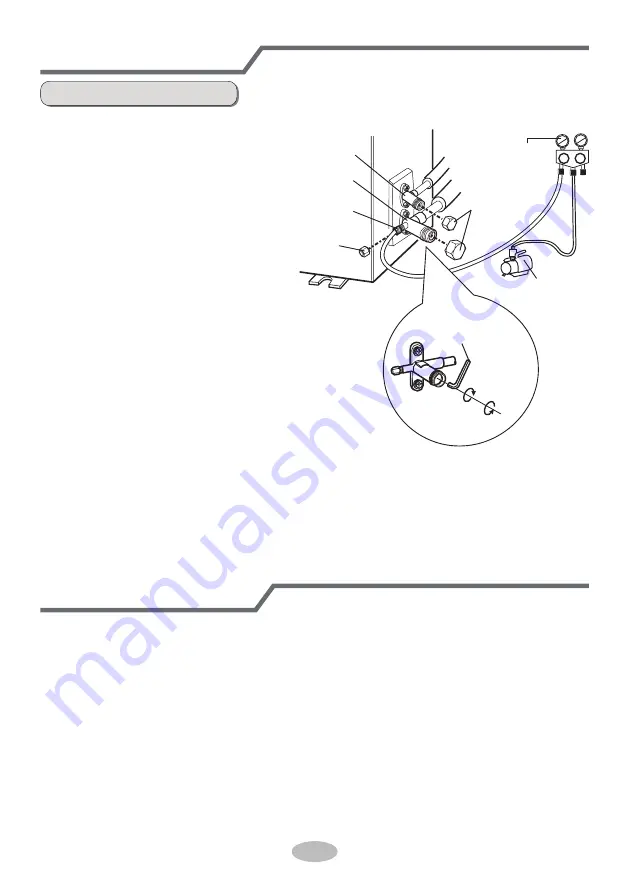

Vacuum pumping

Leakage detection

1. Remove the valve caps on

the liquid valve and gas

valve and the nut of refri-

gerant charging vent.

2. Connect the charging hose

of piezometer to the refri-

gerant charging vent of gas

valve and then connect the

other charging hose to the

vacuum pump.

3. Open the piezometer com-

pletely and operate for

10-15min to check if the

pressure of piezometer re-

mains in -0.1MPa.

4. Close the vacuum pump

and maintain this status for

1-2min to check if the pres-

sure of piezometer remains

in -0.1MPa. If the pressure decreases, there may be leakage.

5. Remove the piezometer, open the valve core of liquid valve and gas valve

completely with inner hexagon spanner.

6. Tighten the screw caps of valves and refrigerant charging vent.

7. Reinstall the handle.

Use vacuum pump

liquid valve

gas valve

refrigerant

charging vent

nut of refrigerant

charging vent

vacuum pump

piezometer

valve cap

Lo

Hi

inner hexagon

spanner

open

close

1. With leakage detector:

Check if there is leakage with leakage detector.

2. With soap water:

If leakage detector is not available, please use soap water for leakage detection.

Apply soap water at the suspected position and keep the soap water for more

than 3min. If there are air bubbles coming out of this position, there's a leakage.

Summary of Contents for ASD18UI-DA

Page 2: ...DOS 9UIDA DOS 12UIDA DOS 18UIDA...

Page 22: ...66129920489...