Page 11 of 48

SK2019 EU FDHD-V/P-AC-001

Valve Information (Optional)

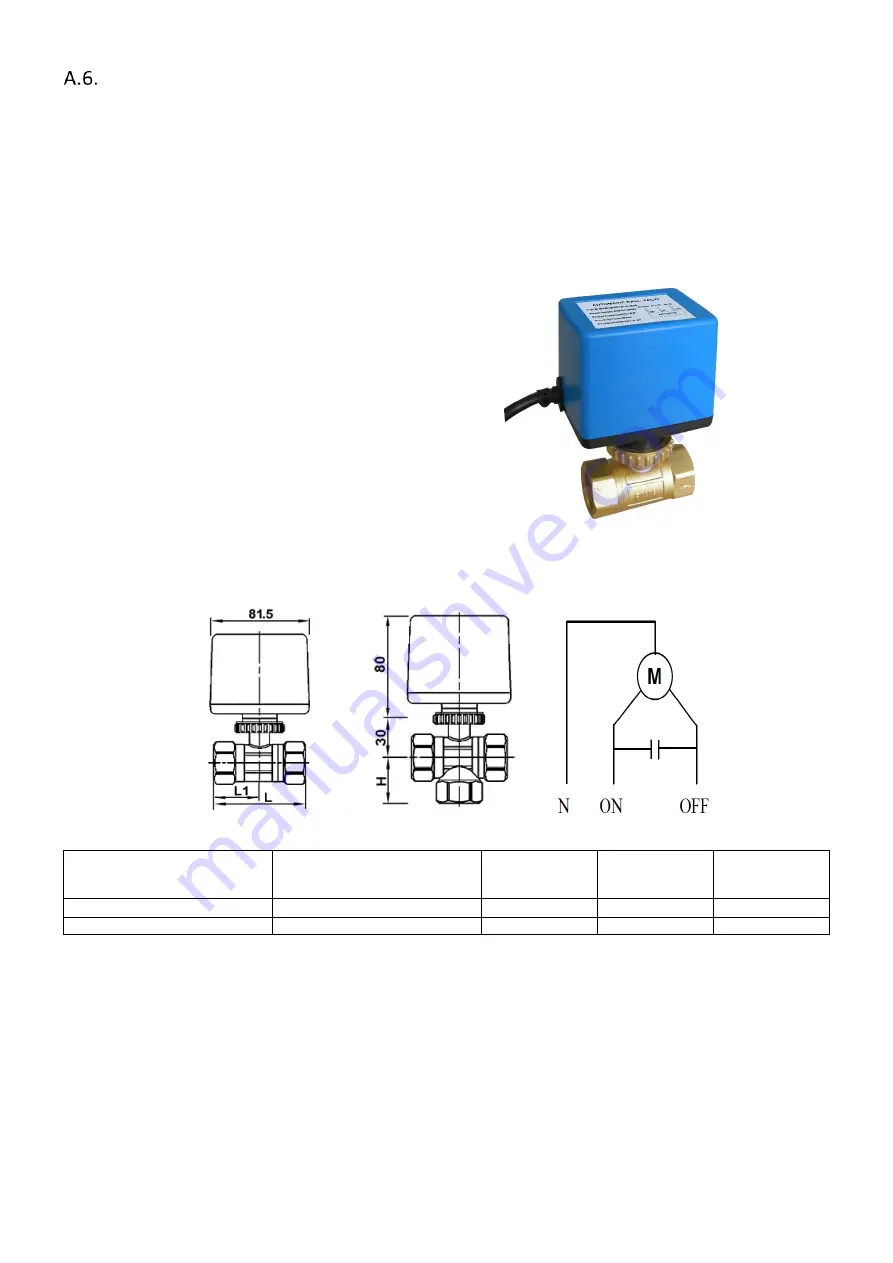

A.6.1.

On/Off Ball Valve Models

Model Definitions

1.

3-

way ball valve with 3/4” connectors and on/ off motorized actuator

2.

2-

way ball valve with 3/4” connectors and on/ off motorized actuator

3.

3-way ball

valve with 1” connectors and on/ off motorized actuator

4.

2-

way ball valve with 1” connectors and on/ off motorized actuator

Specifications

Medium: Cool/Hot water or 60% glycol

Structure: Two way or Three way

Operating Mode: On/Off

Power Supply: AC220V

Power Consumption: 6W (during valve position change)

Running Times: 15 sec.

Pressure Rating: 2MPa

Media Temp. Range: 34°F to 203°F (1°C to 95°C)

Max. Differential Pressure: 1MPa

Body: Forged brass, nickel plated

Ball: Chrome plated brass

Stem: Brass

Seats: Fiberglass reinforced Teflon PTFE

Seal: 2 EPDM O-rings, lubricated

Protection Grade: IP65

Dimensions

Caliber

Inch (mm)

Kv Value

L

L1

H

3/4" (DN20)

7.50

66

33

36

1" (DN25)

13.02

88

44

40

(All dimensions shown in mm)