Page 51 of 62

SK2014

‐

SON

‐

002

‐

TechMnl

‐

FMCD

‐

003

Input

Register

table:

Description

Address

Type*

Remark

Dip

switch

1

status

400000

R

Dip

switch

2

status

400001

R

Room

temperature

sensor

400002

R

Ti1

temperature

sensor

400003

R

Ti2

temperature

sensor

400004

R

Error

code

400005

R

Bit0

=

Room

temperature

sensor

error

Bit1

=

Ti1

temperature

sensor

error

Bit2

=

Ti2

temperature

sensor

error

Bit3

=

Float

switch

error

Bit4

=

Indoor

coil

low

temperature

protection

Bit5

=

Indoor

coil

over

heat

protection

Bit6

=

Reserved

Bit7

=

Electrical

heater

failure

Bit8

=

Motor1

Error

Bit9

=

Motor2

Error

Bit10

=

System

parameters

error

Bit11

=

Reserved

Bit12

=

Reserved

Bit13

=

Reserved

Bit14

=

Reserved

Bit15

=

Reserved

Fan

speed

status

400006

R

Low

=

04(H)

Medium

=

02(H)

High

=

01(H)

Mode

status

400007

R

Cooling

mode

=

01(H)

Dehumidify

mode

=

02(H)

Fan

mode

=

04(H)

Heating

=

08(H)

Setting

temperature

status

400008

R

Testing

only

Room

temperature

in

wall

pad

status

400009

R

Room

temperature

in

main

PCB

status

400010

R

Unit

type

400011

R

4

‐

pipe

=

03,

2

‐

pipe

=

02

This

setting

is

configured

by

dip

switch

EC

motor

1#

RPM

400012

R

EC

motor

2#

RPM

400013

R

*

R

=

read

only,

W

=

write

only,

R/W

=

read

and

write.

Remarks:

The

above

protocol

address

is

Base

0

.

Summary of Contents for FMCD*ECM series

Page 11: ...Page 11 of 62 Dimensional drawing for FMCD 20 24 ECM All dimensionsshown in mm ...

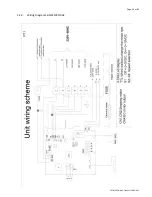

Page 21: ...Page 21 of 62 SK2014 SON 002 TechMnl FMCD 003 C 1 3 Wiring Diagram SK NCFMCD 001 ...

Page 45: ...Page 45 of 62 SK2014 SON 002 TechMnl FMCD 003 C 4 2 Wiring Diagram SK NCFMCD 002 ...

Page 62: ...Page 62 of 62 SK2014 SON 002 TechMnl FMCD 003 ...