34

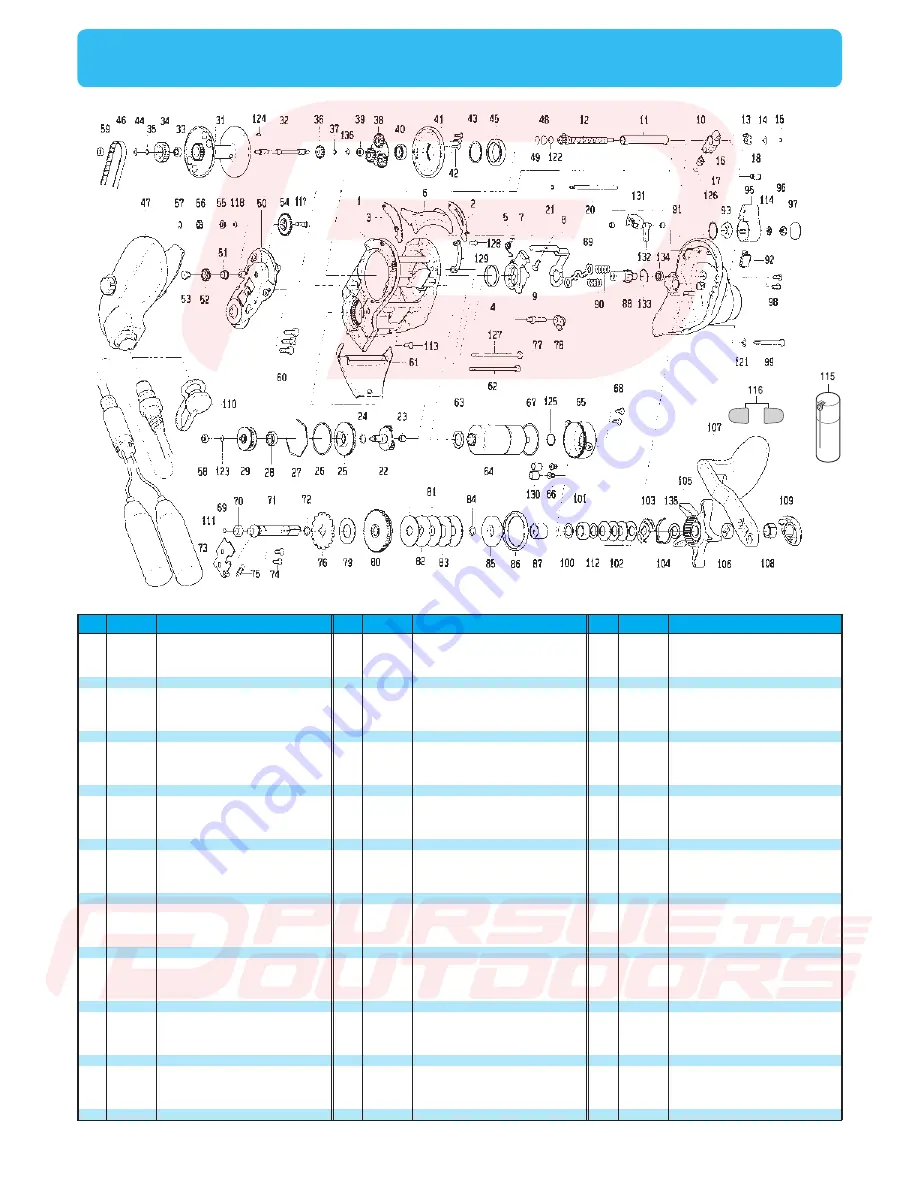

Parts List

SEABORG 300FB

SEABORG 300FB

No,

Parts Name

Parts No,

No,

Parts Name

Parts No,

No,

Parts Name

Parts No,

There may sometimes be a difference between the purchased reel and the Dismantled Parts Chart or the parts list above due to the

adjustment process etc. We appreciate your understanding.

93

95

96

97

98

99

100

101

102

103

104

105

106

107

108

109

110

111

112

113

114

115

116

117

118

121

122

123

124

125

126

127

128

129

130

131

132

133

134

135

136

200

63424001

6G673001

6B962701

6F626201

6B679310

6G502001

6F366802

6F055502

6F673601

6F862901

6B747702

6F863007

6F863202

6G527501

6B862102

6F471207

6F661002

6F598405

63737813

6E134505

61608401

6X148901

6G238201

6G592701

6E096500

6B536101

6F853602

63754100

6G643501

6G659001

6G703201

6G520702

63508912

6G697101

6G701701

6G711001

6G711301

6E219701

6G430901

63737810

63754100

6Y455201

POWER LEVER NUT

POWER LEVER

POWER LEVER NUT

POWER LEVER COVER

R/S PLATE SCREW(A)

R/S PLATE SCREW(B)

HANDLE BALL BEARING WASHER(A)

HANDLE BALL BEARING

DRAG SPRING WASHER

DRAG HOLDER

DRAG HOLDER LEAF SPRING

STAR DRAG

HANDLE COLLAR

HANDLE

HANDLE NUT

HANDLE CAP

CONNECTOR CAP

ELECTRIC POWER CORD

HANDLE BALL BEARING WASHER(B)

FRAME SCREW(B)

POWER LEVER WASHER

REEL GUARD OIL

REEL SHEET PROTECTOR

SET PLATE GEAR PIN

IDLE GEAR(B) WASHER

R/S PLATE SCREW(B) WASHER

MECHANICAL BRAKE WASHER(C)

MOTOR GEAR(B) BALL BEARING WASHER

SPOOL GEAR PIN

MOTOR HOLDER O RING(B)

POWER LEVER O RING

FRAME SCREW(C)

CLUTCH CAM HOLD PLATE SCREW

CLUTCH CAM HOLD PLATE

MOTOR TUBE

CLUTCH CAM LEVER BUSHING

CLUTCH CAM LEVER

R/S BALL BEARING RING

R/S BALL BEARING(CRBB)

STAR DRAG WASHER

SPOOL GEAR BALL BEARING WASHER

OWNER'S MANUAL

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

20

21

22

23

24

25

26

27

28

29

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

6G696201

6F823603

6F823703

6G202701

6G526801

6F824404

6G696301

6G535201

6F211103

6G502601

6G502801

6G521301

6F859101

6F774603

6B864101

6F859401

6G099800

6G625601

6G503301

6B864101

6G696401

6G075601

6F657801

6G502501

6F274501

6B543201

6F016401

6G520801

6G696801

6G504401

6G469001

6G521001

6F550501

6G504501

6F550501

6G504601

6G281602

6G520502

6G505001

6G297002

6F766100

63754100

6G520601

6G521101

6G923401

FRAME

SPACER(R)

SPACER(L)

CLUTCH CAM BUSHING

CLUTCH CAM SPRING

CLUTCH LEVER

CLUTCH CAM

CLUTCH CAM PLATE

CLUTCH LEVER SCREW

LEVELWIND

WORM SHIELD

WORM SHAFT

WORM SHAFT BUSHING(R)

WORM SHAFT WASHER

WORM SHAFT RETAINER

LEVELWIND PAWL

LEVELWIND WASHER

LEVELWIND BUSHING

LEVELWIND POST

LEVELWIND POST RETAINER

MOTOR GEAR(A)

MOTOR GEAR(A) BUSHING

MOTOR GEAR O RING

MOTOR CASE PLATE

MOTOR CASE O RING

MOTOR CASE RING

MOTOR CASE BALL BEARING

MOTOR GEAR(B)

SPOOL

SPOOL SHAFT

SPOOL BALL BEARING(CRBB)

SPOOL SHAFT GEAR(A)

SPOOL GEAR RET(A)

SPOOL SHAFT GEAR(B)

SPOOL GEAR RET(B)

SPOOL GEAR(CRBB)

SPOOL GEAR BALL BEARING(CRBB)

SPOOL PLATE BALL BEARING(CRBB)

SPOOL PLATE

SPOOL PLATE SCREW

SPOOL SHAFT BUSHING WASHER

SPOOL SHAFT BUSHING WASHER

SPOOL PLATE BALL BEARING(CRBB)

MOTOR GEAR BELT

IC MODULE

48

49

50

51

52

53

54

55

56

57

58

59

60

61

62

63

64

65

66

67

68

69

70

71

72

73

74

75

76

77

78

79

80

81

82

83

84

85

86

87

88

89

90

91

92

6F853501

63749102

6G503501

6F853801

6G503601

6F252402

6G592601

6G593401

6G272301

6B864101

6G281605

6G281605

63510901

6G527701

6G520701

6G073001

6G697201

6G501801

6G173401

6F274501

6E134508

6F647201

6E351501

6G697401

6F657801

6F824901

6F211102

6F962801

6F826301

6F826201

6F938801

6F826702

6G697501

6G502402

6F796304

6F796104

6F657801

6G502901

6G697601

6G290901

6G697701

6F826101

6E335301

6G698001

6E286003

MECHANICAL BRAKE WASHER(A)

MECHANICAL BRAKE WASHER(B)

SET PLATE

IDLE GEAR(A) COLLAR

IDLE GEAR(A)

IDLE GEAR(A) SCREW

IDLE GEAR(C)

IDLE GEAR(B) COLLAR

IDLE GEAR(B)

IDLE GEAR(B) RETAINER

MOTOR GEAR(B) BALL BEARING

SPOOL SHAFT BALL BEARING

SPOOL PLATE SCREW

FINGER GUARD

FRAME SCREW(A)

MOTOR WASHER

MOTOR

MOTOR HOLDER

CORD SHIELD

MOTOR HOLDER O RING(A)

MOTOR HOLDER SCREW

DRIVE SHAFT WASHER

DRIVE SHAFT BUSHING

DRIVE SHAFT

DRAG O RING(A)

DRIVE SHAFT WASHER RET

DRIVE SHAFT RET SCREW

KICK LEVER SPRING

RATCHET

ANTI-REVERSE PAWL HOLDER

ANTI-REVERSE PAWL

DRIVE SHAFT WASHER

DRIVE GEAR

EARED WASHER

DRAG DISC WASHER

DRAG LIP WASHER

DRAG O RING(B)

DRAG COLLAR

DRAG COLLAR SHIELD

DRIVE SHAFT COLLAR

PINION GEAR

YOKE

YOKE SPRING

R/S PLATE

LINE HOLDER

pursuetheoutdoors.com/schematics