MODEL:06A-618BR

LUBRICATION

OPERATION

USE ONLY THE AIR TOOL LUBRICANTS SUPPLIED WITH THE

TOOL.

Do not use other lubricants as they may damage the

tool.

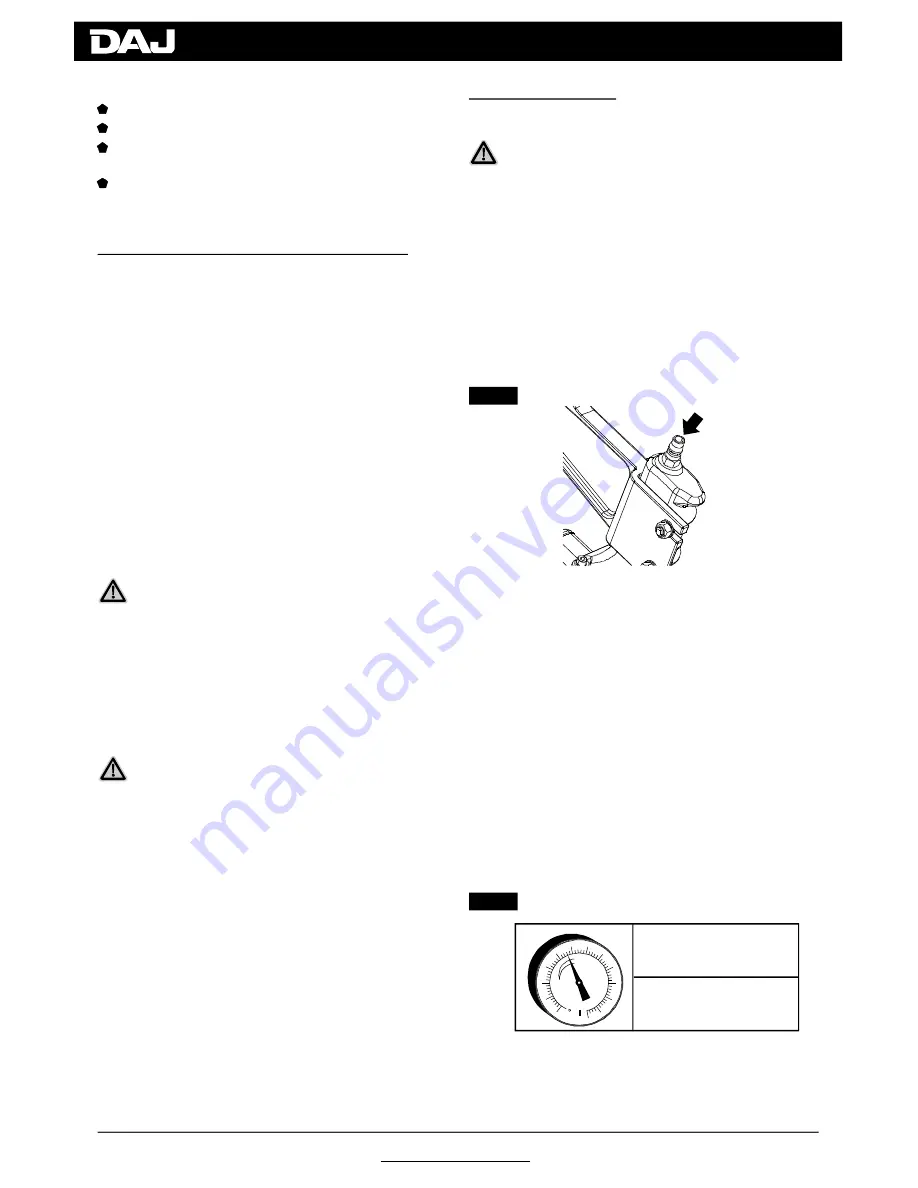

If the tool is not used with an in-line lubrication system on

the air supply it is necessary to periodically lubricate the tool

with air tool lubrication.

Under low use, lubricate once a day. Under heavy use,

lubricate twice a day. To lubricate, insert 2-3 drops of

lubricant into the air supply fitting attached to the tool

handle (FIG 2). Using too much oil will cause it to collect in

the tool and be noticeable in the exhaust.

Do not use detergent oil, WD-40, transmission fluid, motor

oil, or other lubricants not specifically designated as air tool

lubricants. These lubricants will cause accelerated wear to

the seals, o-rings, and bumpers in the tool, resulting in

poor tool performance and frequent maintenance.

2-3 Drops of

Air Tool Lubricant

ADJUSTING AIR PRESSURE

Adjust the air pressure at recommended operating pressure

70-115PSI

The correct air pressure is the lowest pressure which will do

the job. Using the tool at a higher than required air pressure

unnecessarily over stresses the tool. Don't exceed 115PSI.

according to the length of nails and the hardness

of workpiece.

FEATURES

ASSEMBLY INSTALLATION

/

Follow the instructions below to prepare your tool for

operation.

All tool operators and their immediate supervisors must

become familiar with the operator safety instructions

before operating the tool.

Included with each tool are one copy of these

Operating/Safety Instructions. Keep this publications for

future reference.

Install a filter, regulator, lubricator unit and moisture trap

on your air delivery system per the manufacturer's

instructions for these devices. Additionally, install a

pressure gauge as close as practical to the tool,

preferably within 10 feet.

Select hoses with a minimum inner diameter of 1/4

inches and a maximum length of 100 feet.

1.

2.

3.

4.

To reduce the risk of injury from a hose bursting, select

hoses that are rated at least 200PSI.

Select fittings that are appropriately sized for the

selected hoses. The tool and air hose must have a hose

coupling such that all pressure is removed from the tool

when the coupling joint is disconnected.

Never use non relieving couplers and/or female quick

disconnect couplings on the tool.

Non relieving couplings

and female couplings will trap high pressure air in the tool

when the air line is disconnected. This will leave the tool

charged with enough air after it has been disconnected to

drive a nail. Only MALE pneumatic type air connectors

should be fitted to the tool, so that high pressure air in the

tool is vented to atmosphere as soon as the air line is

disconnected.

Set the regulator at the air delivery system to a PSI that

falls within the tool's operating range of 70-115PSI.

The correct pressure is the lowest pressure that will do

the job.

5.

6.

70PSI Minimum

115PSI Maximum

WARNING

WARNING

FIG. 2

FIG. 3

Well balanced hardened driver blade for a longer life.

Ergonomic design for less fatigue.

Composite base to eliminate scratch and damage to the

surface of the wood.

Mallet included.

WARNING

www.chinaairtool.com

04