39

Do not attempt to clean by inserting pointed objects through openings. Sharp edges may damage internal

components and cause a serious hazard.

Ventilation openings, the work contact element, and the trigger must be kept clean and free of foreign matter.

Periodically clean the tool with compressed air.

Clean the magazine. Remove metal or wooden chips which may have accumulated in the magazine.

Periodically clean magazine with compressed air.

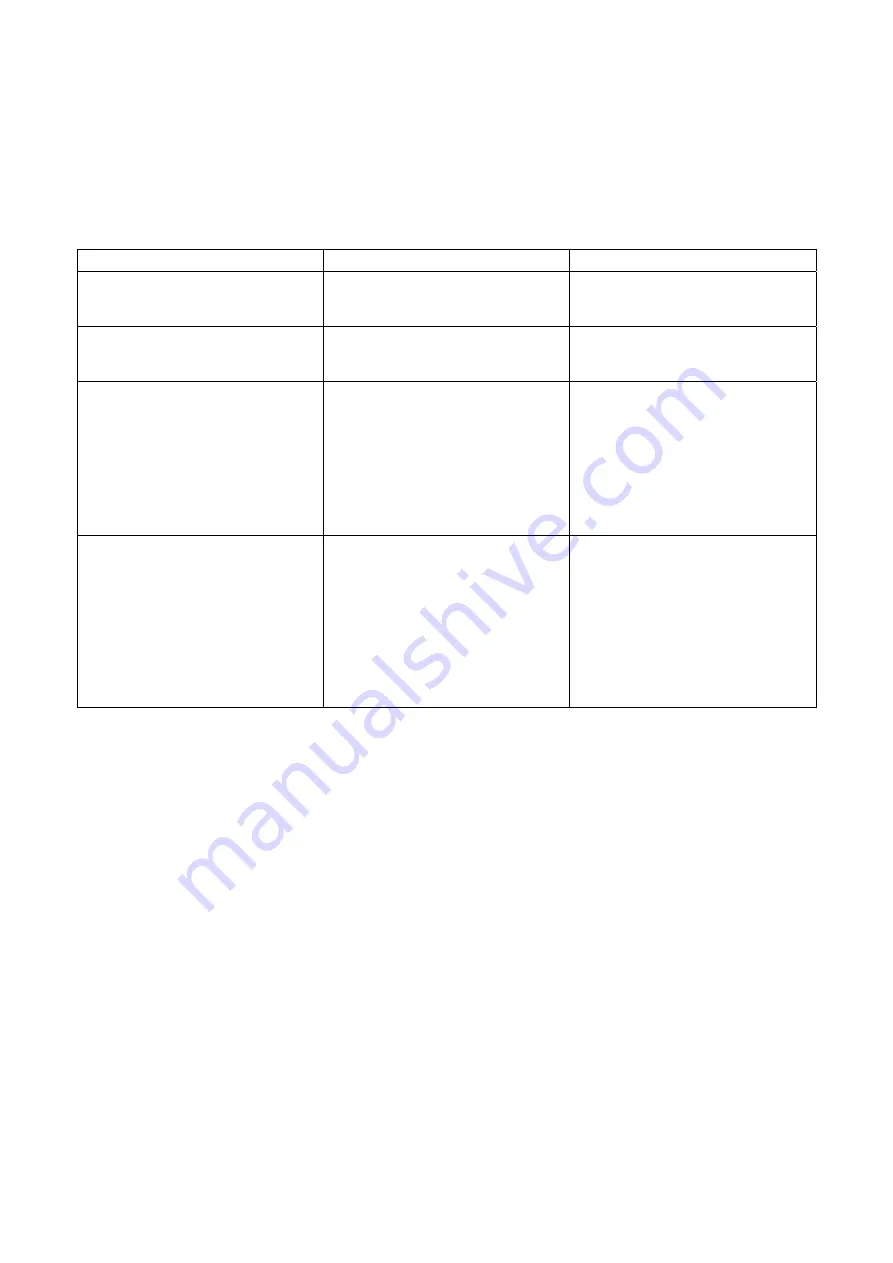

Trouble solving

Problems

Possible causes

Suggested Solutions

Air leaking near the top of the

tool or in the trigger area.

3.

Loose screws.

4.

Worn or damaged O-rings or

seals.

3.

Tighten screws.

4.

Install overhaul kit.

Air leaking near the bottom of

the tool.

3.

Loose screws.

4.

Worn or damaged O-rings or

seals.

3.

Tighten screws.

4.

Install overhaul kit.

Tool does nothing or operates

sluggishly.

5.

Inadequate air supply.

6.

Tool is too dry.

7.

Exhaust blocked.

8.

Worn or damaged O-rings or

seals.

5.

Make sure the air

compressor is set between

70FSI and 115PSI.

6.

Add about 2-3 drops of

lubrication into the air

connector.

7.

Clean exhaust channel.

8.

Install overhaul kit.

Fasteners are jammed in the tool

frequently.

7.

Driver channel is worn.

8.

Piston is broken or worn.

9.

Bent fasteners.

10.

Dirty magazine.

11.

Loose magazine.

12.

Wrong fasteners.

7.

Fix the drive channel.

8.

Replace the piston.

9.

Remove the Dent fasteners,

replaced with the right

fasteners.

10.

Clean magazine.

11.

Tighten screws.

12.

Verify that fasteners are

the correct size.

Summary of Contents for XI3490

Page 1: ...USER MANUAL Heavy Duty Framing Nailer XI3490...

Page 2: ......

Page 85: ...85 Assembly Drawing...

Page 86: ...86 Parts List...

Page 87: ...87...

Page 88: ...88...

Page 89: ...89...

Page 90: ...90...

Page 91: ...91...

Page 92: ...92...

Page 93: ...93...

Page 94: ...94...

Page 95: ...95...

Page 96: ...96...

Page 97: ...97...