8

TROUBLE SOLVING

PROBLEMS

POSSIBLE CAUSES

SUGGESTED SOLUTIONS

Air leaking near the top of

the tool or in the trigger

area.

Air leaking near the bottom

of the tool.

Tool does nothing or

operates sluggishly.

Fasteners are jammed in

the tool frequently.

1. Loose screws.

2. Worn or damaged O-rings or seals.

1. Loose screws.

2. Worn or damaged O-rings or seals.

1. Inadequate air supply.

2. Tool is too dry.

3. Exhaust blocked.

4. Worn or damaged O-rings or seals.

1. Driver channel is worn.

2. Piston is broken or worn.

3. Bent fasteners.

4. Dirty magazine.

5. Loose magazine.

6. Wrong fasteners.

1. Tighten screws.

2. Install overhaul kit.

1. Tighten screws.

2. Install overhaul kit.

1. Make sure the air compressor is set

between 60PSI and 100PSI.

2. Add about 2-3 drops of lubrication into

the air connector.

3. Clean exhaust channel.

4. Install overhaul kit.

1. Fix the drive channel.

2. Replace the piston.

3. Remove the bent fasteners, replaced with

the right fasteners.

4. Clean magazine.

5. Tighten screws.

6. Verify that fasteners are the correct size.

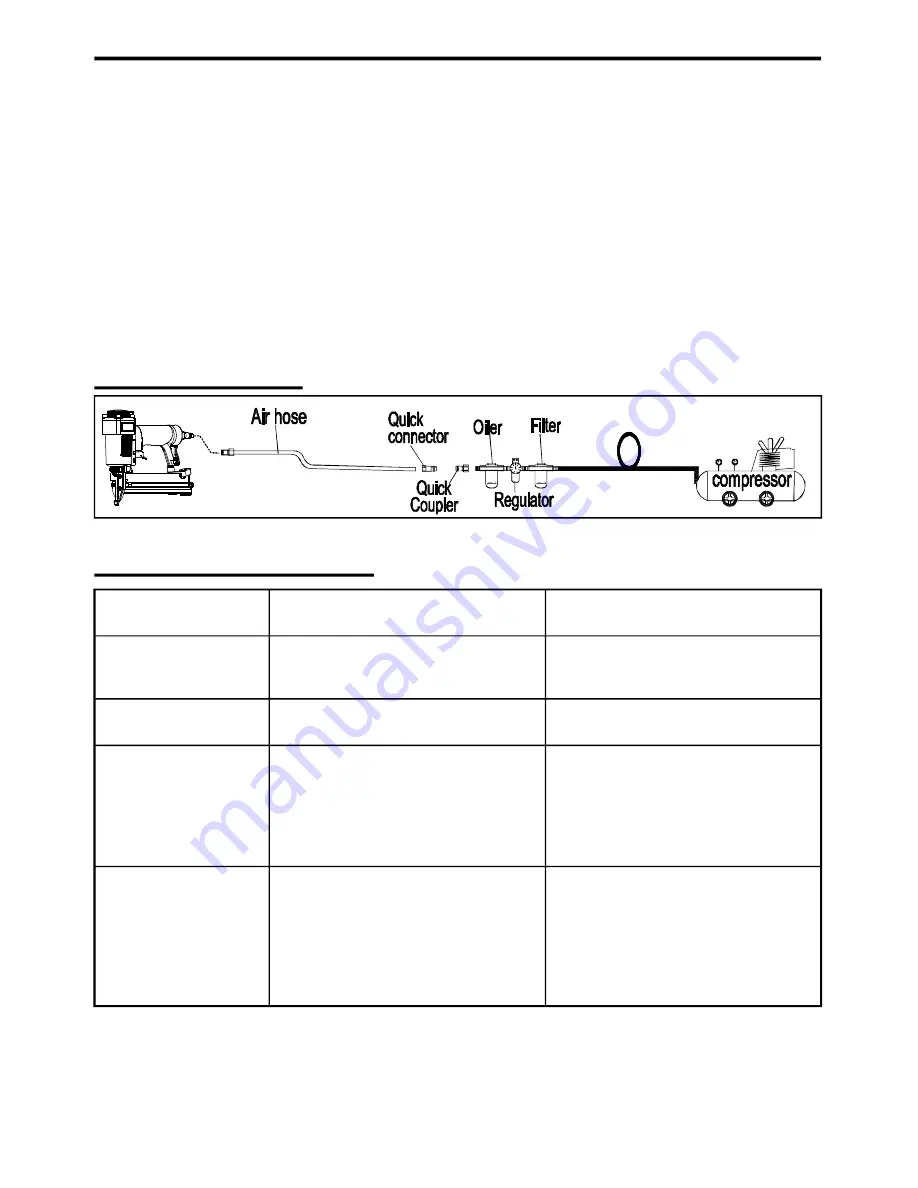

RECOMMENDED

HOOKUP

MINIMUM COMPONENTS

REQUIRED FOR HOOKUP

Air compressor:

Air supply hose:

The air compressor must be able to

maintain a minimum of 60PSI when the nailer is being

used. An inadequate air supply can cause a loss of power

and inconsistent driving.

Pressure regulator: A pressure regulator is required to

control the operating pressure of the nailer between 60PSI

and 100PSI .

Always use air supply hoses with a

minimum working pressure rating equal to or greater than

the pressure from the power source, or 150PSI, whichever

is greater. Use 1/4 inch air hose for runs up to 50 feet. Use

3/8 inch air hose for 50 feet, run or longer.

With ON/OFF switch in OFF position, plug compressor

into electrical outlet.

Close pressure regulator by turning all the way to the

left. Turn compressor ON and let it pump all the way up

to automatic shut-off pressure.

Attach air hose to regulator outlet. Adjust pressure

regulator by turning it to the right so that outlet pressure

is between 60PSI to 100PSI.

Load fasteners into nailer.

Point the nailer in a safe direction while attaching to air

hose.

Nailer is ready for use. You may need to adjust outlet

pressure to achieve proper fastener depth.

1.

2.

3.

4.

5.

6.