Page 14 of 15

DAKA Furnace Model 621

November 2009 Edition

Revision 2: 7-20-12

A = Large Parts Bag #36205

B = Small Parts Bag #36210

All other parts are separate components

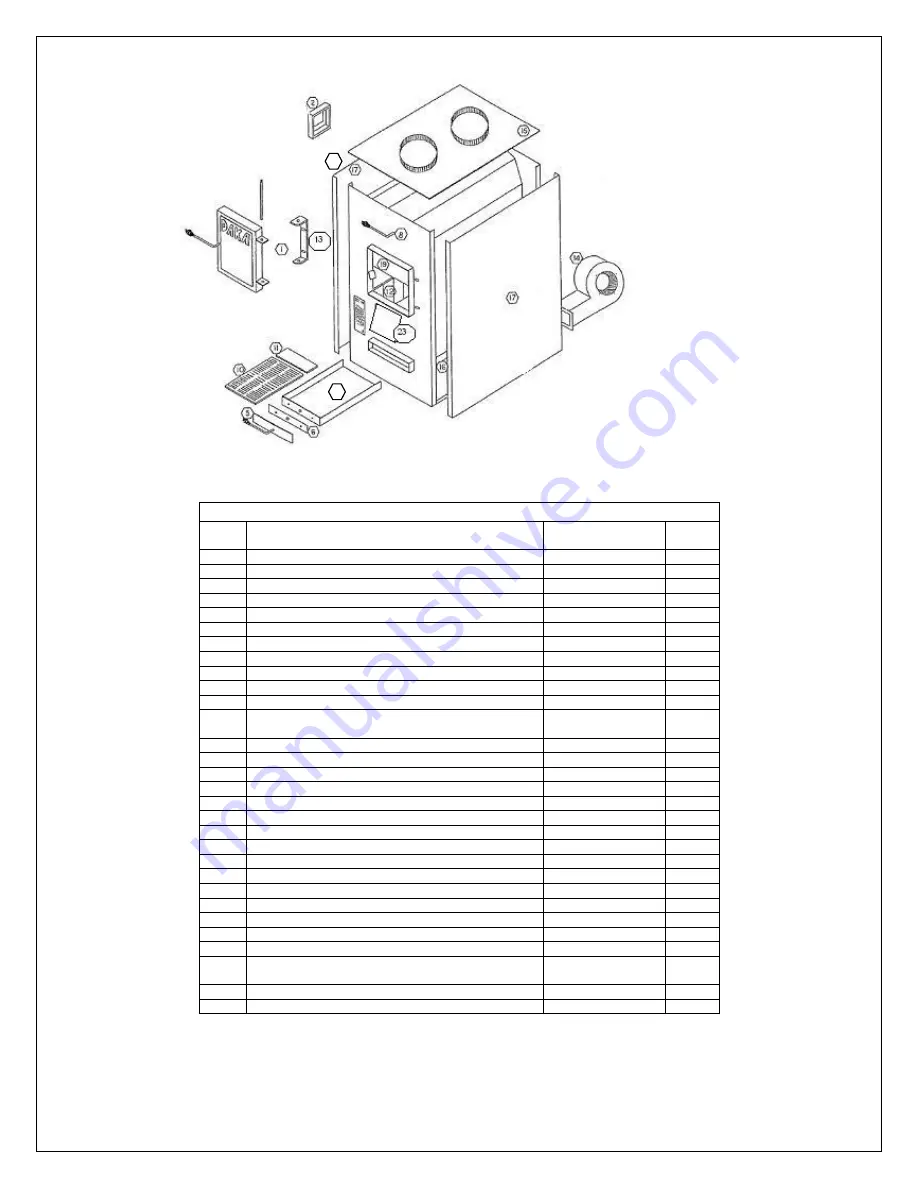

KEY

No. Part Description

Part No.

Qty

1.

Fire Door Assembly

Fire Door Gasket

34200

57610204

1

1

2. Junction Box Assembly - 4x4 (A)

33100

1

3. Number not used

-

-

4. Snap Disc Fan Control (B)

-58640000

-

5. Ash Door Assembly

35100

1

6. Thermal Gasket - Ash Door (A)

57610202

1

7. Ash Pan Assembly

35400

1

8. Bypass Damper Rod & Plate

57590214

1

9. Number not used

-

-

10.

Cast Iron Grate

59650001

1

11.

Grate Spacer (A)

57660001

1

12.

Firebrick

57600001

15

13.

Hinge Assembly (A)

Bolt Bag (B)

30720

36212

1

14.

Blower - 550 cfm

63610004

1

15.

Air Jacket - Top Panel

64590210

1

16.

Air Jacket - Bottom Panel

64590208

1

17.

Air Jacket - Side Panel

64590209

2

18.

Number not used

-

-

19.

Swing Plate (A)

57590211

1

20.

Number not used

-

-

21.

Number not used

-

-

22.

Number not used

-

-

23.

Auto Damper Assembly

32200

1

Flexible Conduit w/wires (A)

62630407

2

Wire Set [inside conduit] (A)

60670006

1

Wire Nut (B)

62630802

4

Sheet Metal Screw

#12 x ½” (B)

61660208

14

Cr

imp. Term. ¼” Female 14 ga. (B)

62670205

2

Conduit Connector

– Straight (B)

Conduit Connector 90° (B)

62670201

62670202

2 (01)

or 1 ea

Hex Bolt, ¼ x ¾ for ash pan door (B)

H1434

2

Hex Nut, ¼ for ash pan door

HN14

2

7

4