Dake Corporation

1809 Industrial Park Dr

Grand Haven, MI 49417

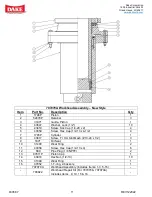

933587

5

REV122022

SET UP

1. Anchor press to floor using 11/16” holes on the base angles of the press.

2. Connect airline from source of supply to Pipe Tee located above operative valve.

3. Fill press with oil. We recommend DTE Mobil 24 or equivalent hydraulic oil.

a. Remove 3/4” pipe plug from reservoir cover and 1/8” pipe plug located on the side of the

reservoir.

b. Fill press with

filtered

oil through the reservoir cover until it starts weeping from the 1/8”

pipe tapped hole on the side of the reservoir. Approximately 5 gallons.

c. Replace both pipe plugs.

OPERATION

HOIST

Press is equipped with hoist and hoist handle to raise and lower the upper platen to desired working

height.

To change the vertical position of the upper platen sufficient tension must be applied to the hoist

cable to permit removal of the table pins, then the upper platen may be moved to desired working

position and all the table pins must be reinserted.

Be sure all table pins are on place before applying any pressure. Also make sure there is

slack in the hoist cable before pressing. It is advisable to lower the upper platen opposed to

running the ram and lower platen to the limit of its stroke.

PRESSING

1. Make sure all the pins (6) are being used and that they are fully inserted in the upper head

channel.

2. Close the pressure release valve handle located on the left-hand side of the press. To do this

pull forward and down on the red handle.

•

Make sure that tires being pressed are centered on the lower platen. Failure to do this

will cause the ram to work at an angle and damage the interior cylinder wall.

3. Once everything is in place and all safety precautions have been made, activate the press by

pushing down on the air valve handle on the left-hand side of the press.

4. The ram will raise the platen at the advance speed until contact is made and pressure is

created then the press will work at the pressing speed until the work is done.

5. Once the cycle is complete and the work has been done, pull out and up on the red pressure

release handle. Once the pressure is removed using the valve handle gravity will return the

lower platen down to its starting position.