Dake Corporation

1809 Industrial Park Dr

Grand Haven, MI 49417

933587

6

REV122022

MAINTENANCE

LUBRICATION

•

Keep all working parts of the press well-oiled for easier operation.

•

Keep a light film of oil over the entire surface of the ram to prevent rust.

REPLACING HYDRAULIC OIL

Recommended to replace hydraulic oil every 6 months of machine use.

*Amount needed may vary dependent on machine use*

TROUBLESHOOTING

When performing any maintenance make sure proper lockout procedure is followed.

When disconnecting any parts of this machine be extremely careful that all parts are clean to

prevent entrance of dirt in the hydraulic system.

A.

Oil leaks around the piston.

1. Oil above the Piston Seal or Leather: If rated stroke of the press is exceeded repeatedly by running

the piston past rated stroke, bypass hole in the side of the cylinder run bypass line that connects

above the piston leather. Eventually enough oil may accumulate so that when the piston is raised to

the top of its stroke, oil is forced out between the piston and piston guide.

This can be remedied by disconnecting the bypass tube line from the cylinder, then raising the piston

slowly, about 2-1/2” less than it’s rated stroke (rated stroke: 18”) allowing the oil above the piston cap

to overflow out the bypass hole into a clean bucket. Replace tube line. Oil may be put back into

reservoir by removing the fill plug on the top of the reservoir.

2. Check Valve not Seated: On the first presses made with rapid advance the bypass oil was returned

through a check valve at the bottom of the reservoir. This has been changed since so that the oil is

returned to the top of the reservoir, above the oil level. Previously, if the check valve failed to seat

properly when the press was operated at rapid advance speed oil was forced back through the by-

pass line causing leakage around the piston. These old-style rapid advance presses can be improved

by relocating the check valve in the inspection cover so that the oil from the bypass line discharges

above oil level.

B.

Press does not hold pressure.

1. Loose tube Connection: Check all connections and tighten any loose tube nuts.

2. Dirt under Release Valve Ball: Remove release valve stem, packing nut, packing, and ball. Clean out

valve seat. Reseat valve ball using a brass rod as a drift and hit with significant force 2-3 times to

reset ball. Reassemble valve. If this occurs frequently the oil should be drained from the reservoir and

the reservoir should be flushed out. Fill reservoir with clean oil.

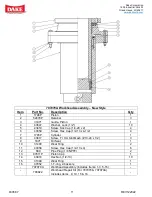

3. Worn Leather Cup or Piston Seal: If neither of the previous conditions seem to be the cause of the

press not holding pressure the trouble may be that the piston leather or T-ring & backers are worn out

or damaged. To inspect remove lower platen and remove cap screws which bolt piston guide to the

cylinder flange. Piston and guide may now be lifted out of the cylinder and inspected or replaced if

necessary. Be careful not to damage the lip of the leather cup or T-ring as it enters the cylinder.