4/29/03

Manual V-16, V-24, VH-24, V-40 & VH-40

11 – Section I

An analysis of the work to be performed should be made and the proper

blade selected. The blade should always be inspected before installing

on the machine. Things to look for should be the smoothness on the

sides and back edge of the weld, look for any missing teeth, or

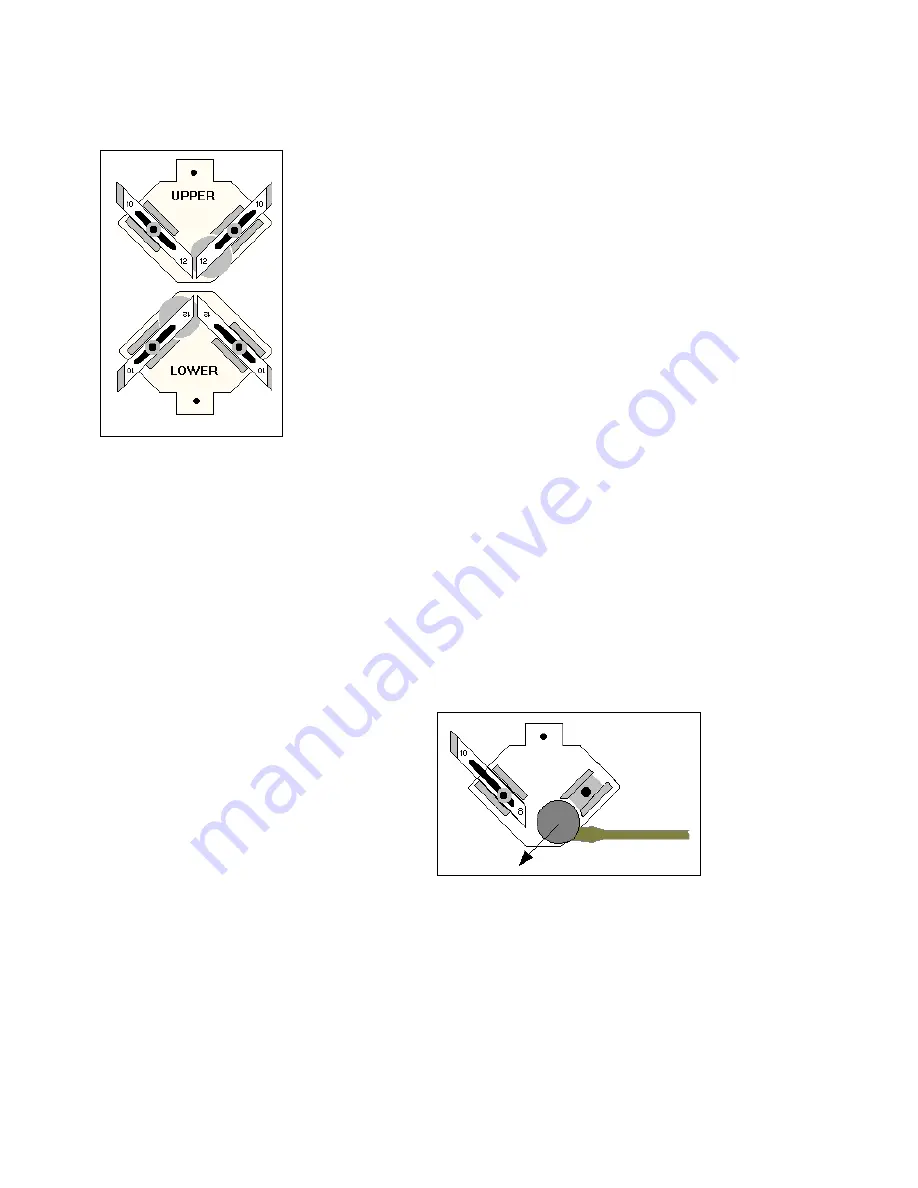

impacted chips. The blade guides may now be selected and inserted

into both the upper and lower guide holders. Proper adjustment of these

guides takes place when they form a complete “V” shape (see graphic

below) and support the blade equally on each side. A couple of

thousands on each side of the blade will provide the running clearance

and support for contour sawing.

Note: Blade guides should be cleaned of chips each blade

change or more frequently if required.

BLADE GUIDES

The back end roller that supports the back of the blade on each guide holder contains a hardened cap

over a set of ball bearings. This should be checked periodically for free movement so it is allowed to

rotate freely as the back of the blade comes in contact with the face of this roller. Noticeable friction in

this assembly indicates it should be replaced. This can be done by removing the right hand guide

insert, moving the left hand guide up away from the bearing face. Loosen the setscrew on the bottom

of the guide holder and sliding the old bearing and shaft out and a new one in. Tighten the setscrew

and re-adjust the guides. See graphic below.

The “V” type solid blade guides and holder assemblies as furnished standard with the machine are

recommended for the majority of cutting applications. This is true for the cutting of materials at blade

speeds in the low range.

If the machine is operated in the high range, it should be operated with the high-speed roller guides,

supplied with this machine, installed.

NOTE: If machine is operated in excess of above, abnormal blade wear and breakage may

occur, due to the increased heat developed with the standard solid guides.