- 17 -

guides for proper spacing.

NOTE: There should be from 000 (just touching) 001 clearance between the blade and guide

bearings to obtain this clearance adjust as follows:

1. The inner guide bearing is fixed and cannot be adjusted.

2. The outer guide bearing is mounted to an eccentric bushing and can be adjusted.

3. Loosen the nut while holding the bolt with an Alien wrench.

4. Position the eccentric by turning the bolt to the desired position of clearance.

5. Tighten the nut.

6. Adjust the second blade guide bearing in the same manner.

REMARK:

1.

Adjust the tension of blade until the back of the blade (A) against the blade wheel (front)

lightly.

2.

Be sure the nut (E) is tightened.

3.

Turn the eccentric shaft (B) counterclockwise, when the bearing (D) touches the saw blade

properly; tighten the nut (E).

4.

To adjust, loosen set screw(F) and move the blade adjustable up or down until it lightly

Touches the back of the blade (A).

5.

The carbide blade guides(L)Fig.1,should also be adjusted so they lightly touch the blade

by loosening screws (M).

6. Repeat 1. 2, 3, 4and 5 steps to adjust the other side's blade guide bearings (G).

7. Correct the base and blade to be a vertical position with a scale. If necessary, loosen set

screw (F).

8. Set down the blade frame, correct the jaw vise (H) and blade to be a vertical position with a

Scale then tighten the set screws (I).

9. Loosen set screw (K), move front jaw vise (J) to against rear jaw vise (H) tightly. Finish

Correcting by tightening set screw (K)

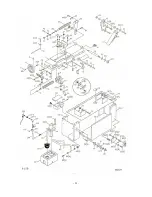

A

C

D

G

L

M

Fig.1

Fig.2

Summary of Contents for SE-912

Page 23: ... 23 ELECTRICAL SPECIFICATION ...

Page 24: ... 24 ...

Page 25: ... 25 ...

Page 26: ... 26 ...