PZX-7

Ultrasonic Multi-Mode Thickness Gauge

37

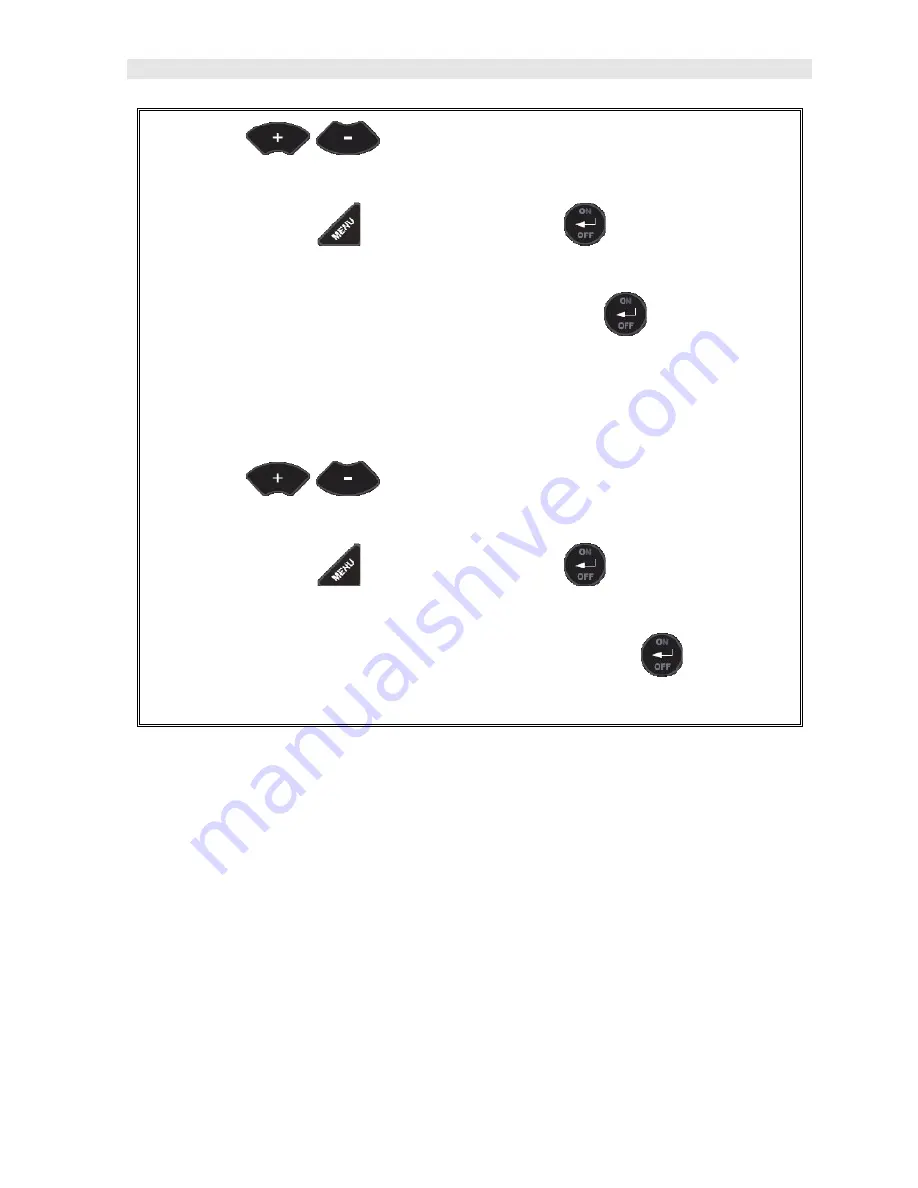

4) Use the

keys to select the contact/delay line/plastics

option.

Note:

Pressing the

key prior to pressing the

key will abort to the

measurement screen without saving changes.

5) When the desired

PROB

type is displayed, press the

key to set the

type and return to the measurement screen.

Note:

If the ‘contact’ option was selected, the diameter of the contact style

transducer must be selected in order to operate correctly.

6) Use the

keys to select the diameter (.125, .250, .375, .500

inches).

Note:

Pressing the

key prior to pressing the

key will abort to the

measurement screen without saving changes.

7) When the desired

PROB

diameter is displayed, press the

key to set

the diameter and return to the measurement screen.

8.9 Velocity (VX)

When the velocity setting (

VX

) is enabled, the

PZX-7

will display will the material

velocity as the primary measurement quantity instead of dimensional thickness. The

feature is generally used for basic “nodularity” testing, as velocity is a key part of

density for determining hardness. An example might be casting manufacturers

where the density/hardness will determine the strength of the material.

When this feature is enabled, the

PZX-7

is operating in reverse to the standard option

of the gauge. Only the ‘one point’ calibration can be used with this feature active,

and a manual or auto zero is still required. The

PZX-7

can be calibrated by entering

the known velocity or entering the know thickness of the material at a given position

on the test material. Refer to the ‘making measurements’ section on page 25 for a

complete explanation of the zero and one point calibration procedure.

Summary of Contents for PZX-7

Page 2: ......