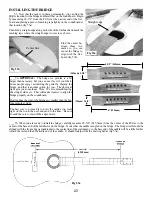

Balance the back panel on a long flat board beneath the centerline to support this pressure. Use long clamps or weights to press

these braces in place with glue (fig 29c). Add scrap wood under the clamps to distribute the pressure evenly over this flexible

flat bracing. Notice the end braces are cut just short of the pencil line marking the heel and tail blocks (fig 29d).

Fig 29c

Fig 29d

Use this curved sanding block to shape and smooth the back

edge of the instrument frame, as shown in fig 30c.

PLEASE NOTE: Keep the sanding block oriented across

the frame as shown, perpendicular to the centerline of the

body. This is the direction of the curve in the back panel,

and it will give you nice firm glue joints around the perim-

eter of the frame when clamping the back in place.

Turn the frame over on top of the back panel and check carefully

to see that the braces do not interfere with the kerfing (fig 30d).

Take your time with this. Trim any braces that are too long to

fit inside the frame. If you end up applying clamping pressure

to an area where the braces are in the way of the kerfing, you

might break something!

_____30. Put double-stick carpet tape on the curved edge of

the large spacer block that was holding the frame (fig 30a).

Fig 30a

Fig 30b

Fig 30c

Fig 30d

14.

Then cut strips of coarse (60 grit) sandpaper to fit along the

edge and press the paper against the adhesive tape (fig 30b).

You may need to butt two strips end-to-end.

Summary of Contents for PARLOR

Page 36: ......