23.

We recommend installing two tiny nails partway into the neck: one near each end, as shown in fig 43b. Clip the nails close to the

wood (fig 43c). These studs will help prevent the fretboard from slipping out of position as you glue and clamp it to the neck.

Replace the fretboard on the neck so the tiny

nails “fall” into the pin-prick dents made earlier.

Remember to leave enough flat space at the peg-

head end for the “nut”.

Fig 43b

Fig 43c

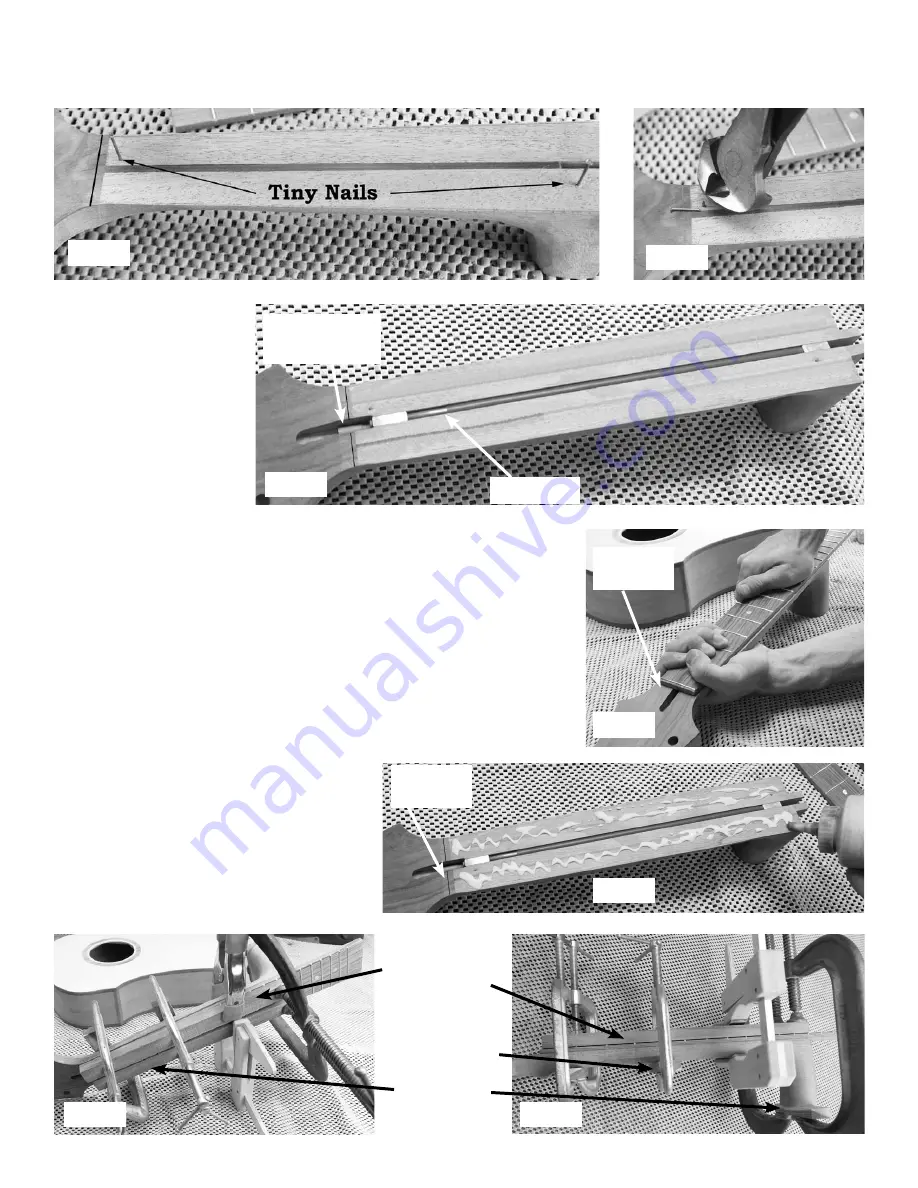

When ready for gluing and clamping, squirt

glue on the neck, as shown in fig. 45b

_____45. Carefully place the fretboard back over the neck, aligning it with your

outline, and leaving enough flat space for the “nut” near the peghead, and press

the fretboard firmly down against the neck, especially where the tiny nails are

located (fig 45a). This will create pin-pricks under the fretboard to keep the

parts from sliding out of position during gluing.

space for

“nut”

Get some clamps and scrapwood ready for clamping the fretboard onto the

neck. Look at the following photos to see how we press these parts together.

Fig 45a

space for

“nut”

Fig 45b

Notice the scrap

wood pads

under the metal

c-clamps. These

are important for

protecting the

instrument wood

from dents

(figs 45c & 45d).

_____44. Push the truss

rod into the slot in the neck,

with the barrel nut fac-

ing the peghead (fig 44).

HINT: We like to orient

the truss rod so the adjust-

ment barrel nut rests at the

bottom of the slot instead of

the top. That is the normal

orientation on production

guitars.

Truss Rod

Fig 44

Barrel nut for

adjustment

Fig 45c

Fig 45d

Summary of Contents for PARLOR

Page 36: ......