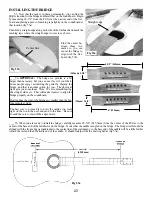

When you determine the correct place for the bridge, use

masking tape to hold it in place while you drill just the outer

two peg holes with a 3/16” bit, as shown in fig 55b. Don’t

risk trying to drill all six holes now - the bridge may slip out

of position.

Assemble the bridge clamp to the bridge as in fig 55c, with the machine screws lightly installed. Test-fit the assembly into the

two holes you just drilled in the soundboard, to make sure everything fits well.

IMPORTANT: the bridge can be installed

backwards!

Be careful to make sure the flat edge closest to the saddle slot is facing the soundhole.

When ready, spread glue on the underside of the bridge and push it down into place with the two screws going through the

soundboard. Reach into the soundhole with one hand to install the washers and wing-nuts on each screw. Then use a Phillips

screwdriver to tighten the two inner screws on the bridge clamp (fig 55d). You should see some glue squeezing out around the

bridge from this pressure.

Make sure to slide a scrap of wood under each of the end screws to

protect the “wings” of the bridge as you screw pressure onto them (fig

55e). We actually use a thin wood scrap with a piece of thick leather

or fabric underneath, to prevent scratching or denting the bridge.

Carefully clean up excess glue with a damp rag, making several pass-

es to scrub away all glue residue.

____56. We like to use a flat mill file to level

the tops of the frets, as shown in fig 56a. You

can use a regular mill file from the hardware

store for this job. We use epoxy glue to adhere

the file to a thick block of wood, creating a nice

handle.

File until all the frets are slightly touched by the

action. That’s when you know they are all the

same height.

Drill two outer-

most peg holes

with 3/16” bit.

Fig 55b

Fig 55d

Fig 55e

Fig 56a

28.

Bridge

Bridge

Clamp

Fig 55c

Summary of Contents for PARLOR

Page 36: ......