Troubleshooting

10

LED

Color

Function Operation

Summary

DS1

Amber

Status

Blinking

DS1 blinks at one second intervals to indicate the

driver is running.

DS2

Green

Power

Steady on

DS2 is on and steady to indicate the driver has

power.

DS3

Red

Signal RX

Steady on

or Blinking

DS3 is on or blinking when the driver is receiving a

signal and off when there is no signal.

Replacing a Driver

If the driver status indicators do not appear to be working correctly, it may be necessary

to replace the driver.

1�

Open the control enclosure by removing the 6 screws and swinging the door open.

2�

Disconnect all plugs from the driver by squeezing together the locking tabs and

pulling the connectors free. It may be helpful to label the cables or take a picture to

know which plug goes to which jack when connecting the replacement driver.

3�

Remove the 4 nuts securing the driver to the control enclosure door.

4�

Carefully lift the driver from the enclosure and place it on a clean, flat surface.

5�

Position a new driver over the screws and tighten the nuts.

6�

Reconnect all plugs to their mating jacks on the driver. The connectors are keyed

and will attach in one way only. Do not force the connections.

7�

Ensure the new driver is set to the correct address and switch settings. This will be the

same as the old driver being replaced. Refer to

Setting the Driver Address (p�10)

and

8�

Close and secure the enclosure door, then power up and test the display to verify the

issue has been resolved.

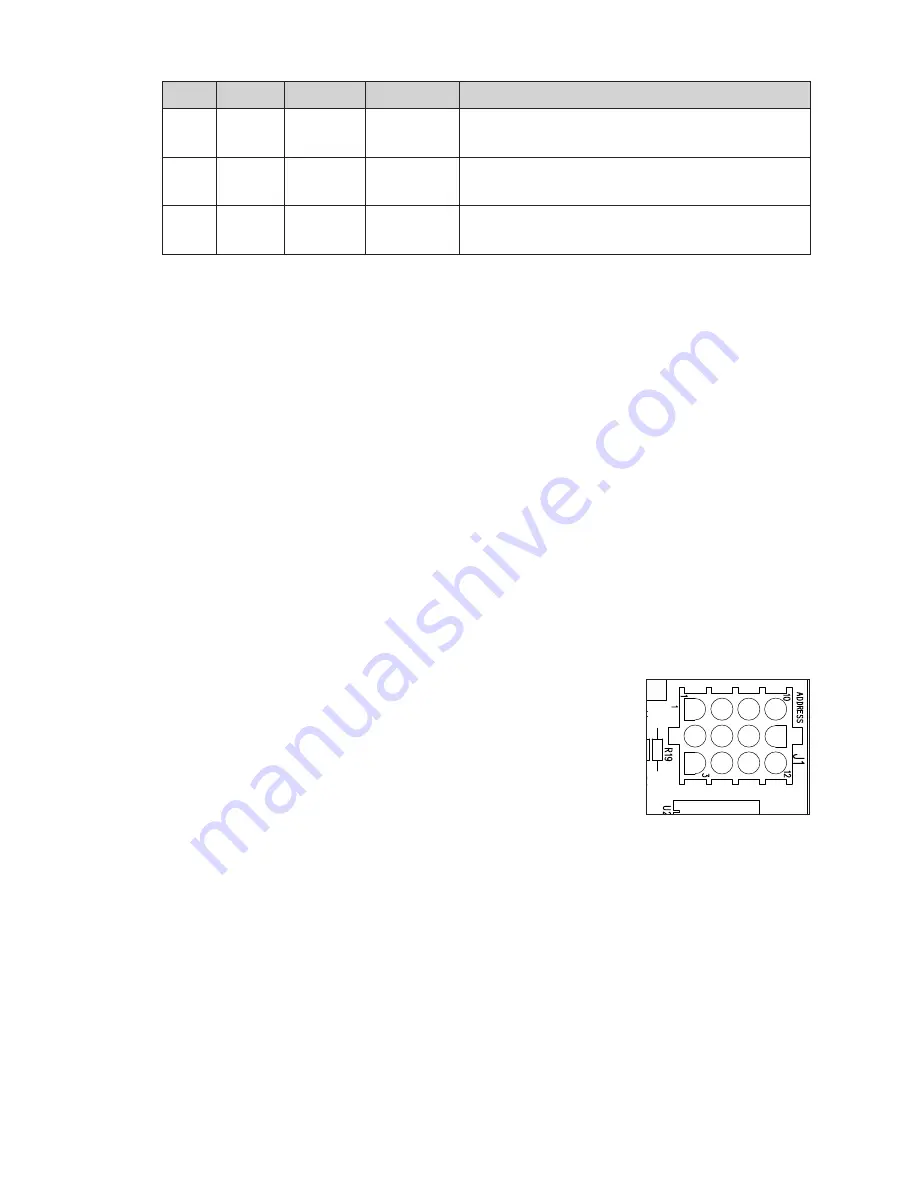

Setting the Driver Address

Since the same LED drivers can be used for many display

models, each driver must be set to receive the correct signal

input, or address, for the model in which it is being used.

This address is set with jumper wires in a 12-pin plug which mates

with jack

J1

driver in the control enclosure, be sure to use an Address 1 plug

in jack

J1

. In most cases, the same plug can be reused from the

driver that was replaced; otherwise, one may be ordered from

Daktronics (part # 0A-1150-0122).

Switch Settings

Reference Drawings:

Schematic: 120V Control Enclosure ...............................................................

DWG-4910448

Schematic: 240V Control Enclosure ...............................................................

DWG-4910665

Digit Switch Settings ..........................................................................................

DWG-4911300

Refer to the schematic drawings for DIP switch settings on the driver that control when

the horn sounds and when backboard light strips illuminate.

Refer to

DWG-4911300

for rotary switch settings on the shot clocks that control when the

shot clock light strips illuminate and if tenths of a second displays on the large or small

shot time digit.

HAZARDOUS VOLTAGE

BEFORE SERVICING

DISCONNECT POWER

Driver Status

Indicators

Shot Clock Driver

Horn Interface Card

Transformers

Figure 5:

Address Jack J1

Summary of Contents for BB-2160

Page 4: ...This page intentionally left blank...

Page 18: ...This page intentionally left blank...

Page 20: ...This page intentionally left blank...

Page 21: ......

Page 22: ......