1

2

3

ENGLISH

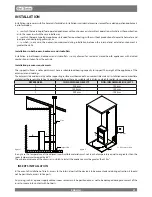

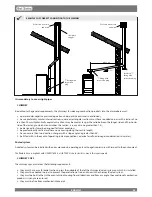

SAFETY DEVICES FOR CLOSED VESSEL SYSTEM

According to the UNI 10412-2 (2009) Standard in force in Italy, the closed systems must have: safety valve, pump control

thermostat, acoustic alarm activation thermostat, temperature indicator, pressure indicator, acoustic alarm, regulation automatic

circuit breaker switch, automatic circuit breaker block switch (block thermostat), circulation system, expansion system, safety

dissipation system incorporated with the generator with thermal safety valve (self-activated), whenever the appliance does not

have a temperature self-adjustment system.

DISTANCES OF SAFETY DEVICES ACCORDING TO THE STANDARD

The temperature safety sensors must be in place on the machine at a distance no greater than 30 cm from the flow connection.

Whenever the generators lack a device, those missing can be installed on the generator flow pipe, within a distance no greater

than 1m from the machine.

COMMISSIONING CHECKS

Before connecting the boiler:

a) wash all system piping in order to remove any residues which might compromise the correct functioning of certain system

components (pumps, valves, etc.).

b) check to verify that the flue has adequate draft, is not narrowed and that other appliances do not discharge into the flue.

This is to prevent unexpected power increases. Only after this control can the flue fitting be mounted between the boiler and

the flue. A check of the connections with pre-existing flues is recommended.

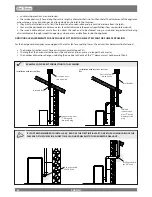

AUTOMATIC THERMOSTATIC MIXER VALVE (MANDATORY)

It is required to create an adequate anti-condensation circuit that ensures a return temperature for the appliance of at least 55°

C. The anti-condensation valve, for example, is applied in solid fuel boilers as it prevents the return of cold water in the heat

exchanger.

Routes 1 and 3 are always open and, together with the pump installed on the return, they guarantee water circulation inside

the biomass boiler exchanger.

A high return temperature allows efficiency improvement, reduces formation of smoke condensation and prolongs the life

span of the generator.

Valves on the market have different calibrations. The manufacturer advises use of model 55°c with 1" hydraulic connections.

Once the valve calibration temperature is reached, route 2 is opened and the boiler water goes to the system via the flow.

Valve sold as an accessory (optional)

45