ROLLOMAXIMUM XL

Page 17

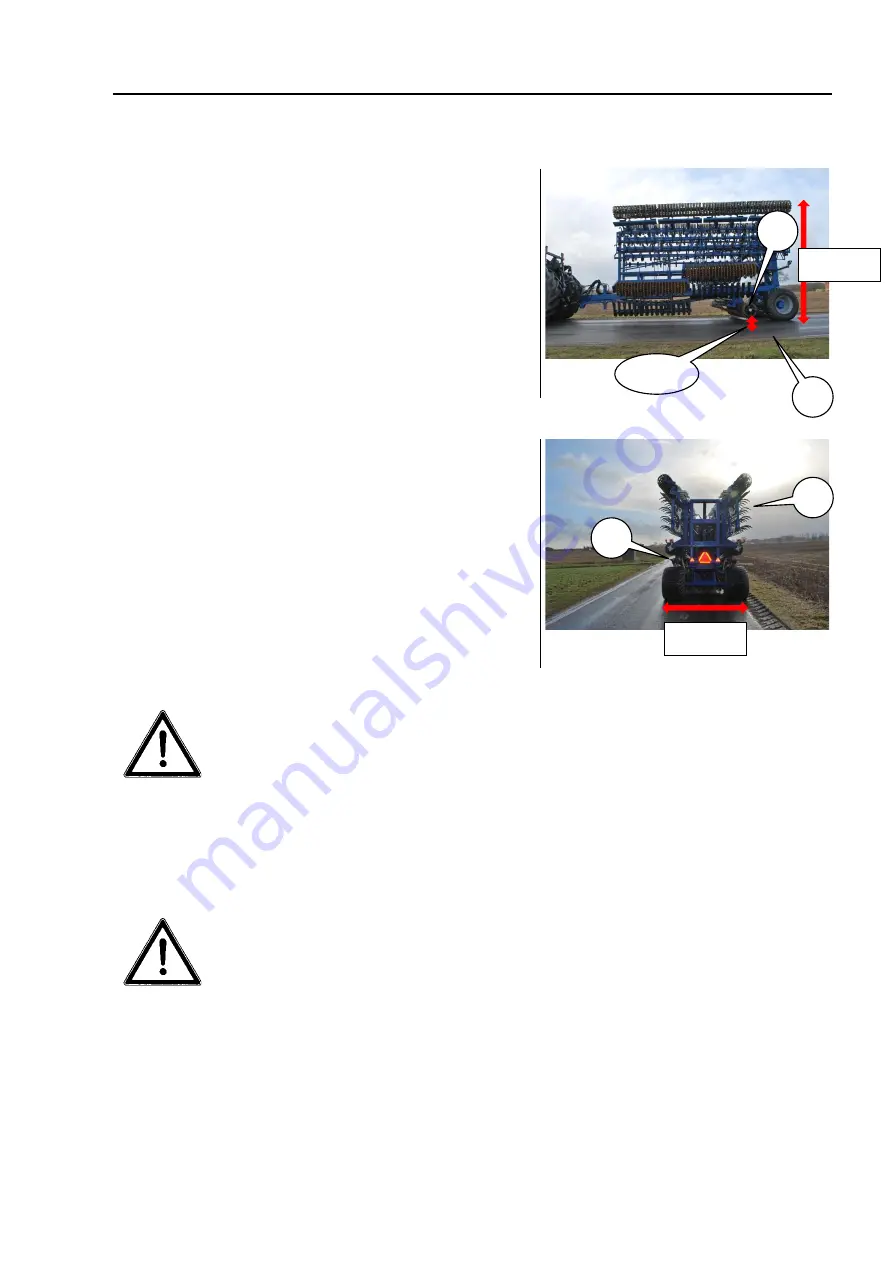

To reduce the height of the ma-

chine's centre of gravity and lower

the transport height to a maximum

of 4 metres, the machine can be

lowered via the wheel frame (A)

(marked: yellow). The machine is

lowered until there is approx. 9 cm

of clearance under the centre

cross-kill axle (B)

To reduce the machine's transport

width to a maximum of 3 metres,

the harrow section is activated (A)

(marked: white valve bock no. 3),

so that they are pulled as far in to

the machine's centre as possible.

The same is done with the ma-

chine's crackerboard (B) (marked:

green)

Always observe the correct sequence when retracting. i.e., the wheel frame

(marked: yellow) is first activated and the machine is lifted off the ground.

The tilt cylinder (marked: white valve block no. 4) is then activated and the

machine is tilted forward until the side frames and the centre frame are in

the upright position. The side frames can then be retracted via the ex-

tend/retract cylinders (marked: red) and are set down on the transport

cradles via the tilt cylinder (marked: white valve block no. 4).

This is very important for the machine's durability and safety that the side

arms remain in the transport cradles, when the machine is transport in the

retracted state.

A

B

9 cm

400 cm

A

B

300 cm