ROLLOMAXIMUM XL

Page 28

1. Fit new gaskets in upper part and collar shoe. The scraper ring is mounted

using a piece of pipe, passed around outside of lip,

(or a special drift). Fit collar (9) onto collar shoe using

tubular bar or screwdriver.

2. Lubricate thread on upper part and cylinder tube with grease (rust-preventing

anti-scratch).

3. Fit upper part (3) to ram shaft.

4. Lock collar shoe (4) and lock nut (10) using Loctite.

Ensure that thread is absolutely clean and free of oil or other

impurities before applying Loctite.

Do not fill with oil for 12 hours after use of Loctite.

5. Lubricate collar shoe (9) and cylinder tube end

inside using lubricating oil. Push ram into centre position.

6. Screw on and tighten the upper part (3).

Replacing the tilt cylinder (white valve block no. 4).

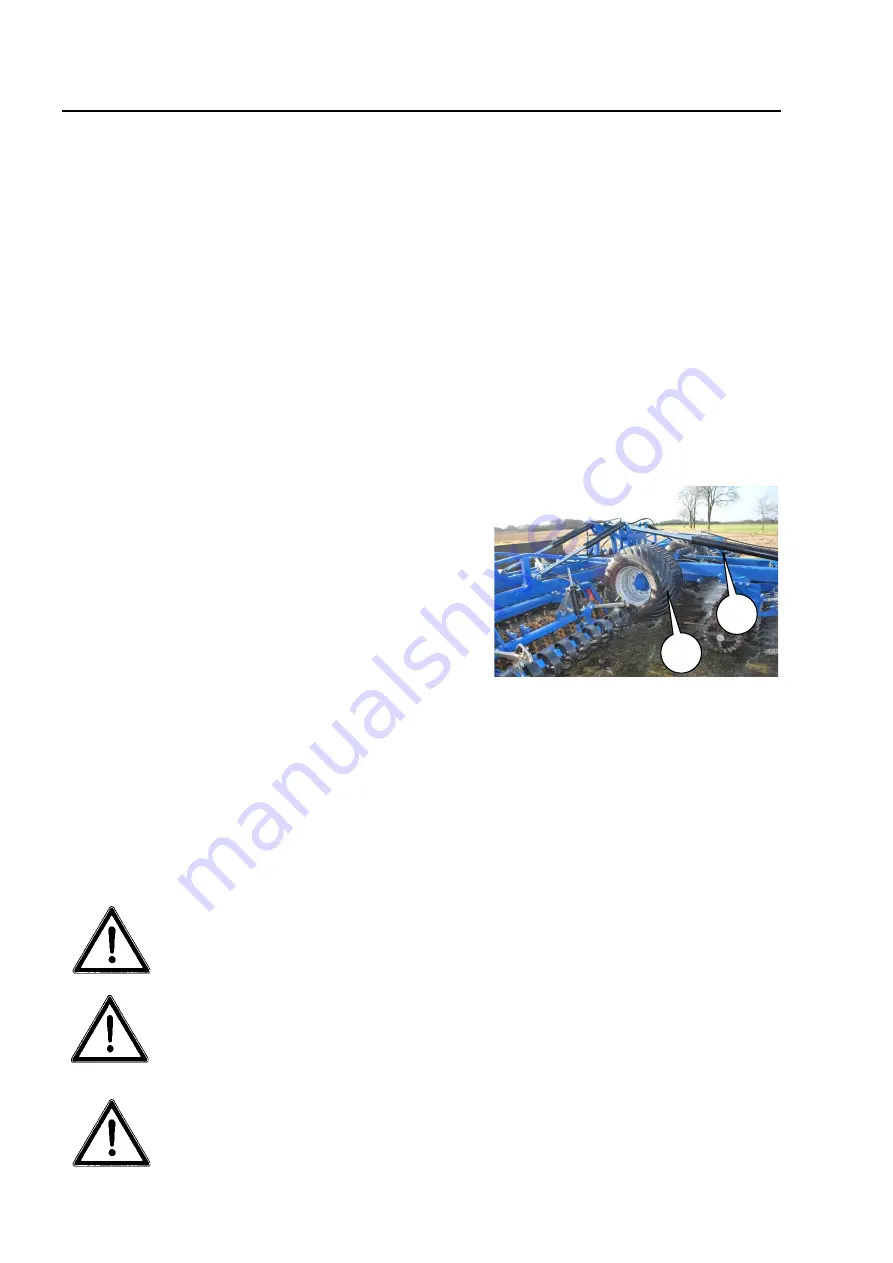

The machine is folded out to the work-

ing position, the wheels (B) are lifted

off the ground and pressure relieved

from the tilt cylinder (A).

1.

Disconnect hoses from cylinder

2.

Support cylinder

3.

Remove split pins from pins, remove pins

4.

Remove cylinder

5.

Fit new or repaired cylinder

After fitting the tilt cylinder, it is actuated until the cylinder shows a slight travel.

Reverse cylinder until it returns to start position. Move cylinder backwards and

forwards several times.

If cylinder is not bled correctly as described above, there is a risk that part of the

machine can suddenly move much quicker than normal, and before the tractor

driver can prevent it. This is because air (unlike oil) is compressible. A section can

therefore swing out very quickly if air bleeding is not performed correctly. This rep-

resents a major risk of injury to personnel and of damage to the machine.

Ensure no personnel are within the extension radius of the side sections.

A

B