www.dalemans.com

DAT420_MAN02_EN.docx • V1R1

9

DAT 420

Exemples

:

Calibration gas

(CAL

Gas

)

ppm

Measuring range

300 ppm

500 ppm

1000 ppm

5000 ppm

I

Measure

mA

V

Measure

mV

I

Measure

mA

V

Measure

mV

I

Measure

mA

V

Measure

mV

I

Measure

mA

V

Measure

mV

0

4.00

40.00

4.00

40.00

4.00

40.00

4.00

40.00

50

6.67

66.70

5.60

56.00

4.80

48.00

4.16

41.60

100

9.33

93.33

7.20

72.00

5.60

56.00

4.32

43.20

200

14.67

146.67

10.40

104.00

7.20

72.00

4.64

46.40

250

17.33

173.33

12.00

120.00

8.00

80.00

4.80

48.00

300

20.00

200.00

13.60

136.00

8.80

88.00

4.96

49.60

500

20.00

200.00

12.00

120.00

5.60

56.00

1000

20.00

200.00

7.20

72.00

2000

10.40

104.00

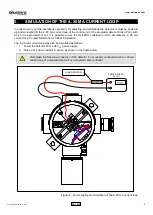

9.

On the control unit/PLC to which the detector is connected, check that the reading corresponds

accurately to the value of the concentration of calibration gas applied.

10. Stop applying calibration gas, remove the calibration mask and check that the reading on the

voltmeter drops to its rest value of 40 mV and that the reading shown on the control unit/PLC drops to

zero.

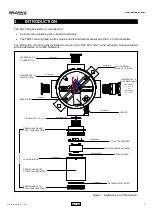

11. Check that the sensor and transmitter are correctly positioned on their supports. Screw on the body of

the sensing head and tighten the locking screw (Figure 5 – Page 6).