Reference

Version

Document

Lang.

Page

244-ENG

09-01-2018

244 DAN DRYER Turbo (with nozzle)

Maintenance and service manual

ENG

3 of 12

DAN DRYER A/S • Tåsingevej 2 • DK-8940 Randers SV • Tel: +45 86 41 57 11 • Email: info@dandryer.dk

Installation and connection:

To protect the user against electric shock, it is important that the hand dryer is connected to the earth wire.

For fixed installation, connect via circuit breaker.

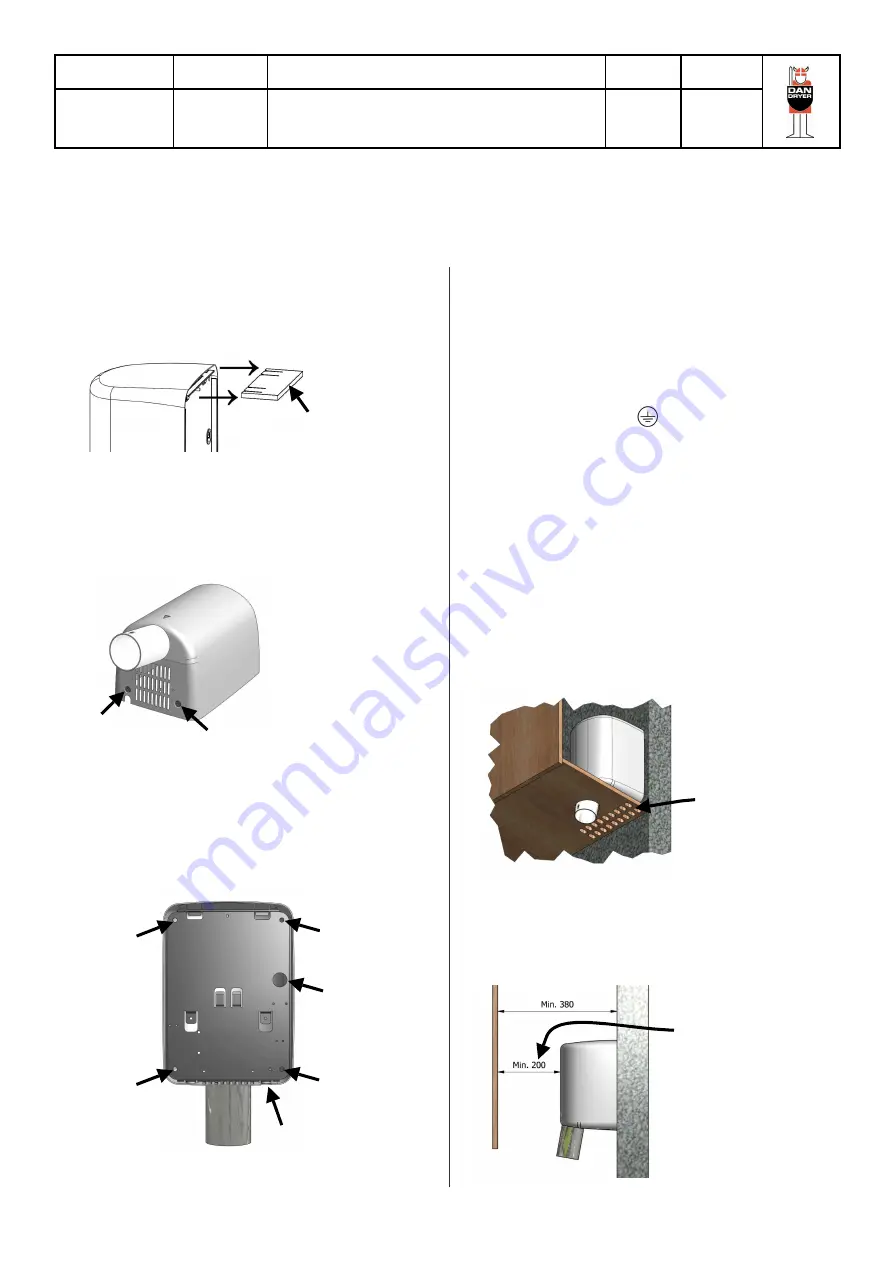

Remove the

cover screws

Remove the

cover screws

Transport

protection block

Cut-out for

wiring through

the bottom

Hole for wall

mounting

screw

Hole for

hidden wiring

Hole for wall

mounting

screw

Hole for wall

mounting

screw

Hole for wall

mounting

screw

1. Remove transport protection block prior to

installation.

2. Remove the two cover screws at the bottom of

the cover using the supplied special Allen key.

Carefully remove the housing from the base

plate.

3. Attach the base plate to the wall using

appropriate screws in the four mounting

holes. Wiring can be hidden behind the

machine or may alternatively be fed through

the bottom of the cover.

4. Connect wires as follows:

A. Connect the live wire (red or brown) to the

terminal block marked ”L”.

B. Connect the neutral wire (blue or black) to

the terminal block marked ”N”.

C. Connect the green and yellow earth wire to

the screw marked ” ”.

5. Remount the cover using the two cover

screws at the bottom of the cover and

test run the hand dryer.

If the machine is mounted in an enclosed

cabinet, it is important to be aware of the

following requirements:

If the hand dryer is installed in an enclosed cabinet

it is important that there is enough space to

remove the hand dryer's cover so the machine is

easily accessible for cleaning or servicing.

Total area of ventilation

holes must be at least

35 cm

2

per hand dryer.

If the cabinet has a fixed

front plate, there must

be at least 200 mm

space to dismantle and

remove the hand dryer's

cover.

Do not lift the

hand dryer by

the electrical

parts during

installation.

The turbo hand dryer sucks a large amount of air

during operation. It is therefore important that the

cabinet/housing has ventilation holes of at least

35 cm2 for each hand dryer.