Reference

Version

Document

Lang.

Page

244-ENG

09-01-2018

244 DAN DRYER Turbo (with nozzle)

Maintenance and service manual

ENG

5 of 12

DAN DRYER A/S • Tåsingevej 2 • DK-8940 Randers SV • Tel: +45 86 41 57 11 • Email: info@dandryer.dk

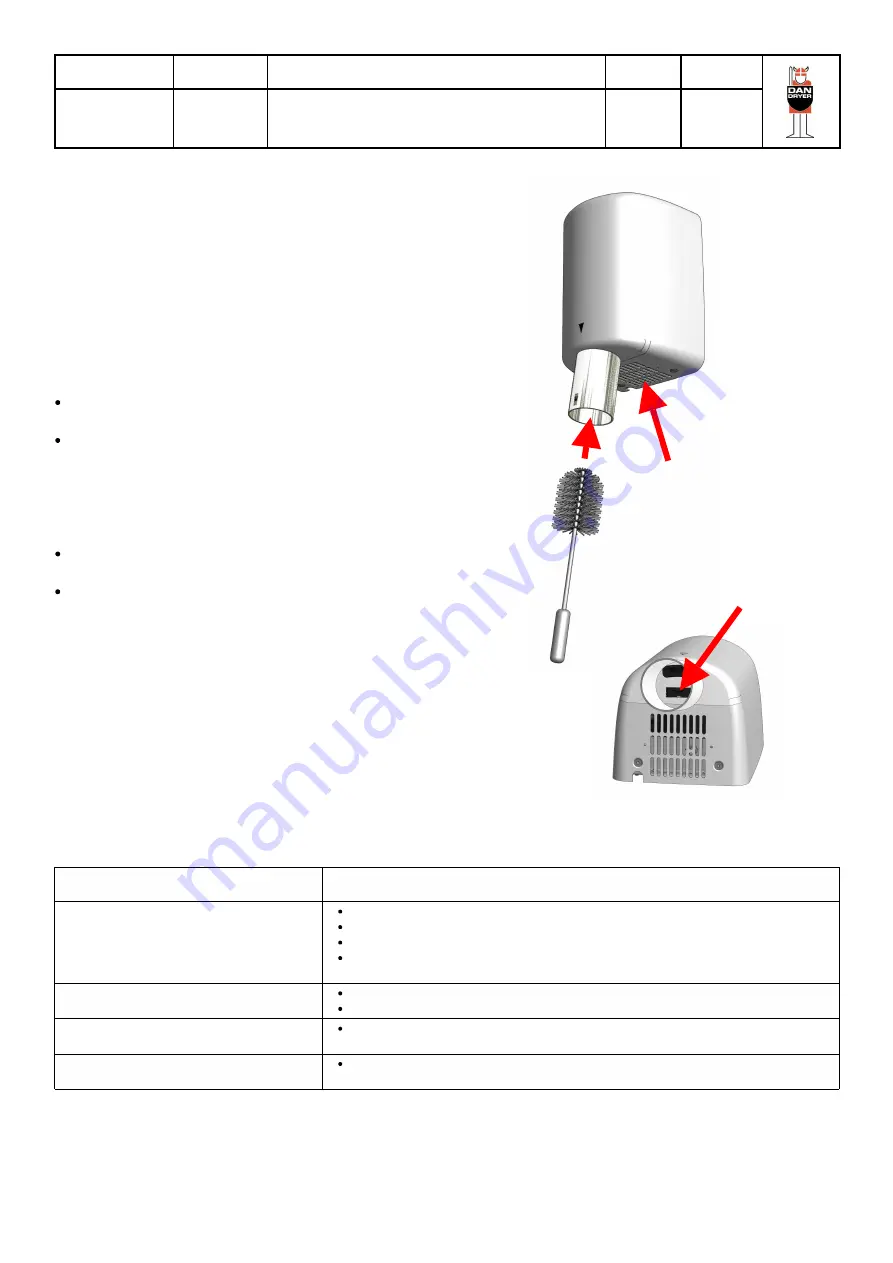

Regular maintenance:

To ensure a continued satisfactory function of the hand

dryer it is recommended regularly to remove dust etc. from

the machine.

The frequency of cleaning depends on the environment in

which the hand dryer is installed and how often it is used.

If the machine is used often cleaning is recommended at

least once a month.

Exhaust pipe and sensor must be cleaned with a damp

brush (available from DAN DRYER)

Cleaning / vacuuming of the air intake holes in the hand

dryer's cover and any air intake holes in the cabinet /

furniture.

If the machine is rarely used, we recommend cleaning

once every 6 months.

Exhaust pipe and sensor must be cleaned with a damp

brush (available from DAN DRYER)

Cleaning / vacuuming of the air intake holes in the hand

dryer's cover and any air intake holes in the cabinet /

furniture.

In the event that the machine is used extensively and the

environment is very dusty, it may be necessary to clean

the inside of the machine regularly. See more in the

section "Cleaning the inside of the machine"

Cleaning / vacuuming

of the air intake holes

Important: To ensure correct

function the IR sensor must

always be completely clean.

Problem:

Solution:

Hand dryer does not start:

Check the 230V power supply.

Check IR sensor for dirt or damages.

Check that all electrical connections, wires etc. are intact.

If none of the above actions corrects the problem, it is either the IR sensor, the

coal brushes or the timer that causes the problem and must be replaced.

Blows cold air only:

Heating element unit has been overheated and must be replaced.

Timer is defective and must be replaced.

Poor air flow:

Dirt and dust in inlet and outlet impair the air flow. Clean the machine and

cabinet in accordance with the section "Regular maintenance"

Other problems not covered by this guide:

If the problem is not resolved by the above actions the entire hand dryer unit

must be sent for repair to DAN DRYER or replaced with a new one.

Trouble shooting:

IMPORTANT:

If the unit is returned to DAN DRYER it must be accompanied by a detailed description of

the problem.