46

Dana Incorporated

IMM-0017EN - Installation and Maintenance Manual

11 TROUBLESHOOTING GUIDE

Table 11:

WARNING

All the operations bellow must be done by authorized and skilled mechanician/electrician.

Inform Dana Motion Systems Italia S.r.l. before making any change to the gearbox. Only oil change is allowed to change with-

out information. Do not make any think if you are not sure what you are doing and contact Dana Motion Systems Italia S.r.l..

Any change or operation done without the information of Dana Motion Systems Italia S.r.l. is in your own risk and responsibility

and Dana Motion Systems Italia S.r.l. does not take any responsibility.

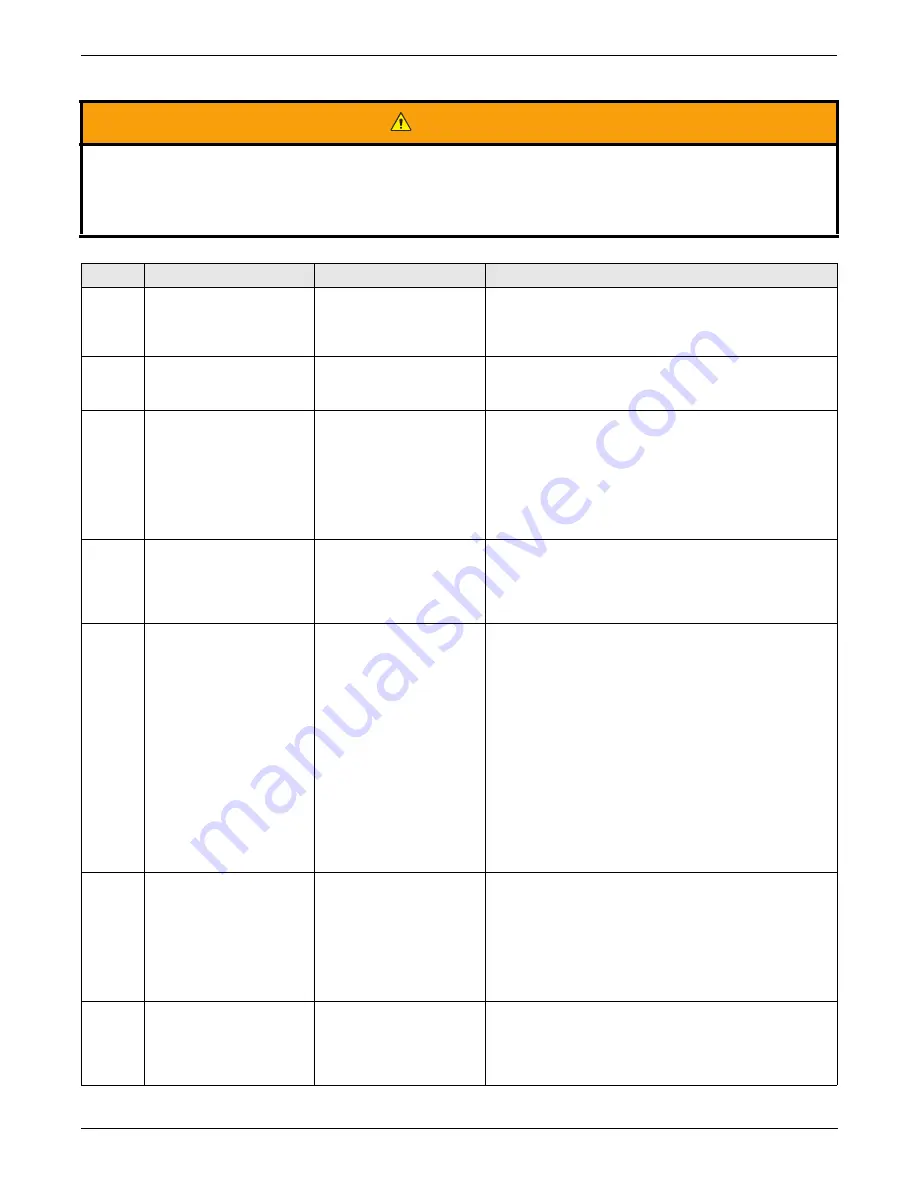

ID

Problem

Observation

Remedy

001

Gearbox Does Not Start Up

You hear no noise and shaft is

not turning. You are not using

any driver or frequency invert-

er.

Please Check the voltage supply and frequency of your electric

connection. They must be in accordance with the nameplate of

the motor. Observe motor manufacturers start up manual. Still

does not work go to ID 100

002

Gearbox Does Not Start Up

You hear no noise and shaft is

not turning. You are using fre-

quency inverter or driver.

Please observe the frequency incerter/driver manual. Chech the

motor by supplying direct voltage to see if the problem is on your

driver/frequency inverter. Still does not work go to ID 001.

003

Gearbox Does Not Start Up

You hear some noise but both

motor shaft and gearbox shaft

is not turning. You are not us-

ing any driver /frequency in-

verter or braked motor.

Please Check the voltage supply and frequency of your electric

connection. They must be in accordance with the nameplate of

the motor. Observe motor manufacturers start up manual. Still

same problem, the load may be too high for the choosen motor.

Loosen the gearbox from the load/torque. If it works than the

starting torque is insufficient and higher motor power is needed.

For monophaze motors, check the starting up condansator and

running condansator as well. If notting helps go to ID 100

004

Gearbox Does Not Start Up

You hear some noise but both

motor shaft and gearbox shaft

is not turning. You are using

driver or frequency inverter.

Please observe the frequency inverters or drivers manual. To see

if the problem is on your driver or frequency inverter take out the

driver/frequency inverter and make direct voltage supply to the

motor according the motors nameplate. Still does not work go to

ID 100

005

Gearbox Does Not Start Up

You hear some noise but both

motor shaft and gearbox shaft

is not turning. You are using

braked motor

Please Check the voltage supply and frequency of your electric

connection. They must be in accordance with the nameplate of

the motor. Observe motor manufacturers start up manual. Be

sure that the brake is working. Observe the brake manufacturers

manuel. If brake is supplied from Dana Motion Systems Italia

S.r.l. observe this manuel for correct brake wiring diagram. If still

not work supply the brake with voltage according its nameplate

directly. For example 198V DC. You will hear a clicking noise ex-

plaining that the brake is opening. If you hear no noise the brake

or rectifier is defect. If you hear the clicking noise the brake is

working. You should this clicking noise by your normal electric

connection as well. By supplying direct supply to the brake you

hear the clicking noise and at same time you supply the motor

with direct voltage according to its name plate and still same

problem, the load may be too high for the choosen motor. Goto

ID 003.

006

Gearbox Does Not Work in

Low Speeds/frequencies.

You are using frequency in-

verter.

For very low speeds the frequency inverters frequency is lower-

ing down. For very low frequencies the inverter parameter and

motor parameter must be optimized. Also for low speeds the ef-

ficiency of the gearbox may varry too much. Specially for worm-

gearboxes. The recomended frequency range is 20-70 Hz for

worm-gearboxes and 10-70 Hz for Helical Gear Boxes. Use

Higher motor power and Frequency inverter or change ratio of

gearbox to work inside the reccomended range.

007

Gearbox Does Not Start

Mornings or After Long Time

Stop.

Ambient Temperature is be-

low +5 Celsius

The oil is not in accordance with your working conditions.

Change to lower viscosity oils. Observe this manuel for using the

correct oil. Working in higher ambient temperatures is an other

solution if possible. If still same problem you need higher motor

power.