Installation Guide

CONFIDENTIAL

TG-0057_19 TM4 SUMO HD CO300-A1_A2_A2.5 Installation Guide

© Dana TM4 inc., 2013-2020

Page 24 of 42

2020-11-20

Table 3

Grounding – Strap size

Specifications

Units

Values

Wire size

AWG (mm

2

)

1/0 (50 mm

2

)

Notes:

As long as the wire size of the grounding strap is equivalent to the size of the wire coming from the high-voltage

battery, it should be adequate to withstand a short circuit between the high-voltage battery and the chassis.

For the location of the grounding point on the MCU, see Figure 7; for screw specifications and mounting

points that can also be used as ground points, see the product interface drawing [11].

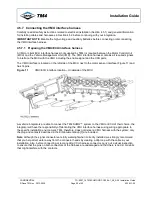

Figure 7

Grounding point

Note:

Prepare the provided zinc-coated bolt with Loctite 242 or 243 before insertion. One screw is provided for

grounding purposes.

Table 4

Grounding strap installation

First end

Second end

Refer to Figure 7

Vehicle chassis (frame) or earth ground (test bench)

Note:

The location of the second end connection point of the grounding strap given here is an example; the actual

location will depend on the type of application being used by the vehicle integrator.

4.5.4.3 Connecting the grounding strap – Chassis

When the grounding strap is to be connected to the vehicle chassis, prepare the chassis by removing the

paint from the contact area, then sand and apply a layer of conductive grease before connecting the strap.

It is important to note that when integrating the system, both the motor and MCU must be grounded in the

same place on the chassis, or at least on the same connected frame before checking that the resistance

between the chassis and another metallic part of the vehicle is less than 0.1 Ohm.