– 2 –

Connector

Details

MDM-7

™

Drive Module Operator’s Manual

Figure 1

Danaher Motion

•

Precision Systems Group

•

7C Raymond Avenue, Salem, NH 03079

tel:

603.893.0588

•

toll free:

800.227.1066

•

fax:

603.893.8280

•

url:

www.danaherprecision.com

All MDM-7 module functions are brought out on a single 12 pin

screw-clamp style connector. To attach leads to the connector,

simply insert solid or standard wire in the 18 to 26 gauge range

and tighten the screw clamp. Specific pin functions are detailed

below.

Pin #1: Power Supply Ground

This pin, which is internally tied to pin #12, is to be connected to

the user provided D.C. power supply ground. Power supply

ground should be connected to the chassis to which the module

is mounted. To minimize radiated EMI (electrical noise), this

ground should also be connected to the shield enclosing the

motor leads. This shield should be extended to the motor case,

minimizing electrical noise generation by the motor.

Pin #2 Power Supply V+

This pin is to be connected to the user provided D.C. power sup-

ply positive lead. This supply need not be regulated, and can

range from +24 to +60 volts D.C. Care must be exercised that

power line fluctuations and power supply ripple do not exceed

the 60 volt maximum rating. For best operation, power supply rip-

ple should be held to 1 volt peak to peak or less. High speed

torque and power are proportional to the D.C. supply value;

accordingly, higher supply voltages will provide increased perfor-

mance. The penalty paid for this performance is increased motor

and module heating, as well as increased power supply weight

and volume.

Due to the efficiency of the recirculating drive design, total power

supply current requirements are reduced to approximately 1/3 of

the motors phase current rating for full coil operation, and 2/3 of

the current rating for half coil operation (for information on the

meaning of the terms “full coil” and “half coil,” (see next page).

These current requirements are significantly reduced at idle, light

torque loading, and low speeds.

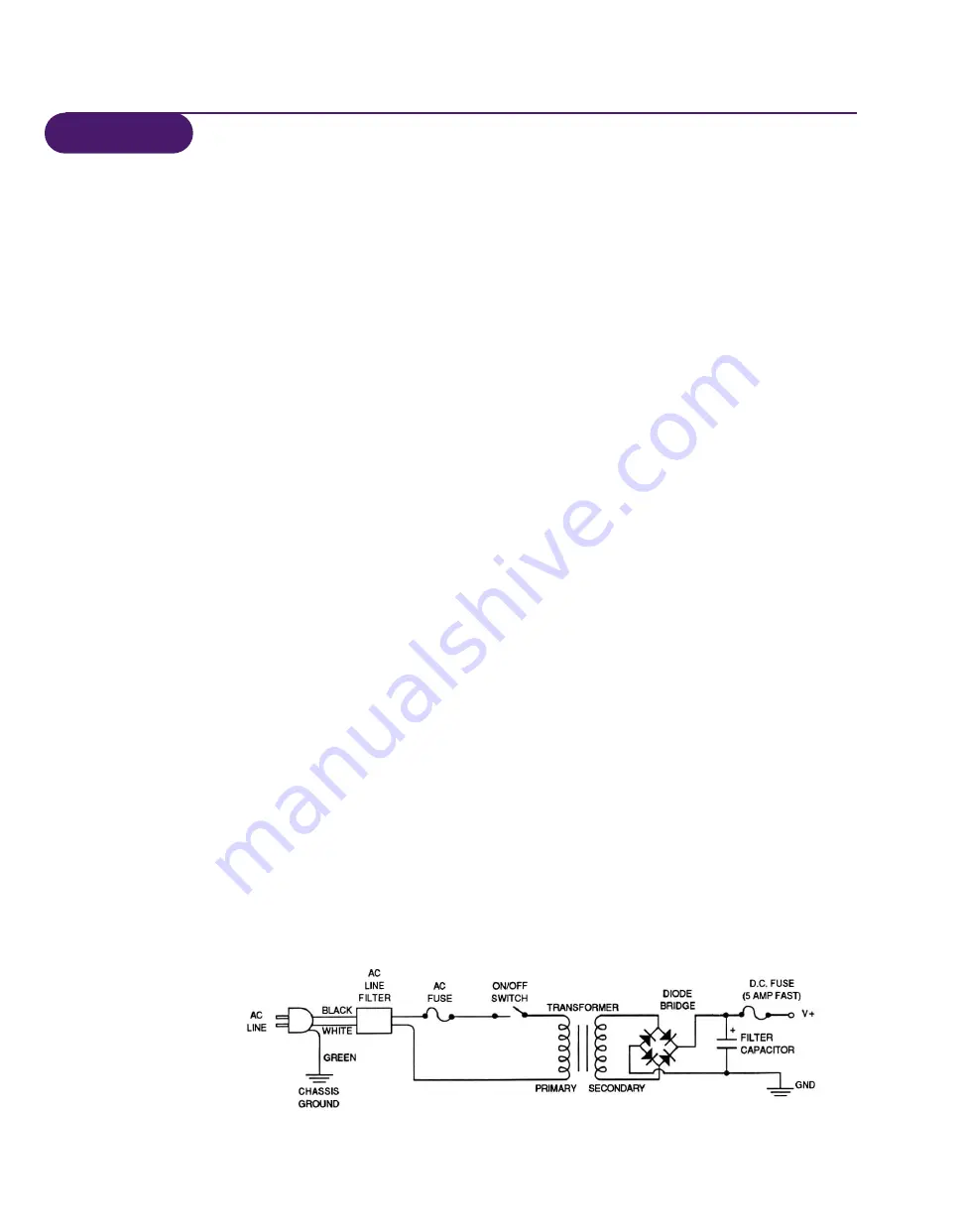

For users building their own unregulated D.C. power supplies, Fig.

1 details a typical design. It consists of an A.C. line filter, A.C.

fuse, on-off switch, transformer, diode bridge, filter capacitor, and

D.C. fuse. The transformer primary voltage should coincide with

the line voltage (115 V.A.C. or 230 V.A.C.), while the transformer

secondary voltage should equal .7 times the desired D.C. supply

voltage (for example, a transformer secondary voltage of 30 volts

A.C. will be required for a D.C. supply voltage of 42 volts). The

secondary current requirement should be 1.4 times the desired

D.C. supply current. For example, a stepping motor rated at 2.6

Amps per phase, and operated in half coil mode, will require a

D.C. supply current of 2/3 * 2.6, or 1.73 Amps. This corresponds to

a transformer secondary current rating of 2.45 Amps A.C. The fil-

ter capacitors value, in microfarads, should equal 8000 times the

D.C. supply current (14000 microfarads in the above example) to

ensure a ripple voltage below 1 volt. Smaller capacitors will also

work, but result in increased supply voltage ripple. This can

impair performance if the motor is required to produce close to

its maximum torque output.

A 5 Amp, fast blow fuse must be inserted in the positive side of

the D.C. power supply, to protect against motor shorts to ground,

etc. As described below, the motor MUST be wired in place

before D.C. power is applied. Never connect or disconnect the

motor while D.C. power is applied. The power supply leads (V+

and GND) should be kept as short as possible. If these leads

exceed 10 inches, install both a .1 mfd. and 100 mfd. capacitor

rated at 100 volts or higher across pins #1 and #2 at the drive

module.

Pins #3 and 4: Motor Coil 1

Pins #5 and 6: Motor Coil 2

WARNING! No connection or disconnection of the motor leads

should be performed while the module D.C. power supply is

active. Always wire the motor leads prior to applying D.C. power.

If connectors are present along the motor cable, always turn off

D.C. power prior to connecting or disconnecting the motor. The

extremely high voltage, fast rise-time transients produced when

the motor is connected or disconnected can destroy the FET out-

put stage of the MDM-7 module. Damage caused by motor con-

nection/disconnection with power applied is not covered under

the DPS warranty.