Kollmorgen

SYSTEM WIRING

SERVO

STAR

®

SP3 Power Block

17

STANDARD OPTION

The Standard Option has a single connector. It is located on the front of the unit. Connector C2

interfaces between the SP3 and an external Delta Tau (or compatible) digital interface board,

such as the Accessory 8F. Connector C2 is a standard mini-D-36 connector, with the pin

descriptions below. A compatible point-to-point cable can be supplied by Delta Tau Data

Systems, Inc.

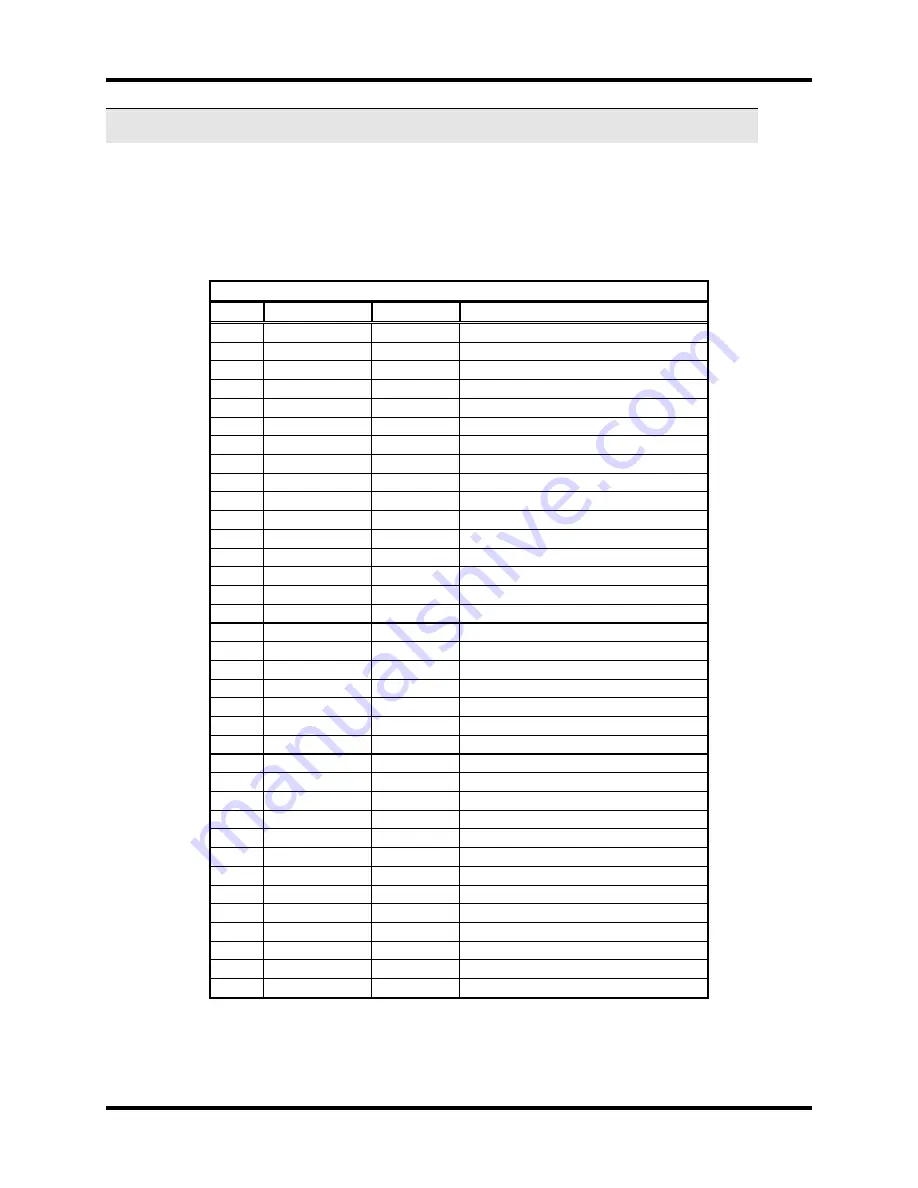

Connector

C2

(Standard Option)

Pin Symbol

Function Description

1

FC0

Feedback

Fault code bit

2

FC2

Feedback

Fault code bit

3

Command

A/D converter clock

4

Command

A/D converter strobe

5

C Feedback

Phase A actual current data

6

C Feedback

Phase B actual current data

7 AENA+

Command Amplifier

enable

8 FAULT+

Feedback Amplifier

fault

9

Command

Phase A top command

10

Command

Phase A bottom command

11

Command

Phase B top command

12

Command

Phase B bottom command

13

Command

Phase C top command

14

Command

Phase C bottom command

15 PMAC_GND Common Reference

voltage

16

PMAC_+5V

Power

+5V power from controller

17 NC

18 NC

19

FC1

Feedback

Fault code bit

20

FC3

Feedback

Fault code bit

21

ADC_CLK-

Command

A/D converter clock, return

22

ADC_STB-

Command

A/D converter strobe, return

23

CURRENTA-

Feedback

Phase A current data, reference

24

CURRENTB-

Feedback

Phase B current data, reference

25

AENA-

Command

Amplifier enable, return

26

FAULT-

Feedback

Amplifier fault, reference

27

PWMATOP-

Command

Phase A top command, return

28

PWMABOT-

Command

Phase A bottom command, return

29

PWMBTOP-

Command

Phase B top command, return

30

PWMBBOT-

Command

Phase B bottom command, return

31

PWMCTOP-

Command

Phase C top command, return

32

PWMCBOT-

Command

Phase C bottom command, return

33 PMAC_GND Common Reference

voltage

34

PMAC_+5V

Power

+5V power from controller

35 NC

36 NC

www.szcxi.com | From

:

KOLLMORGEN