4

MOUNTING

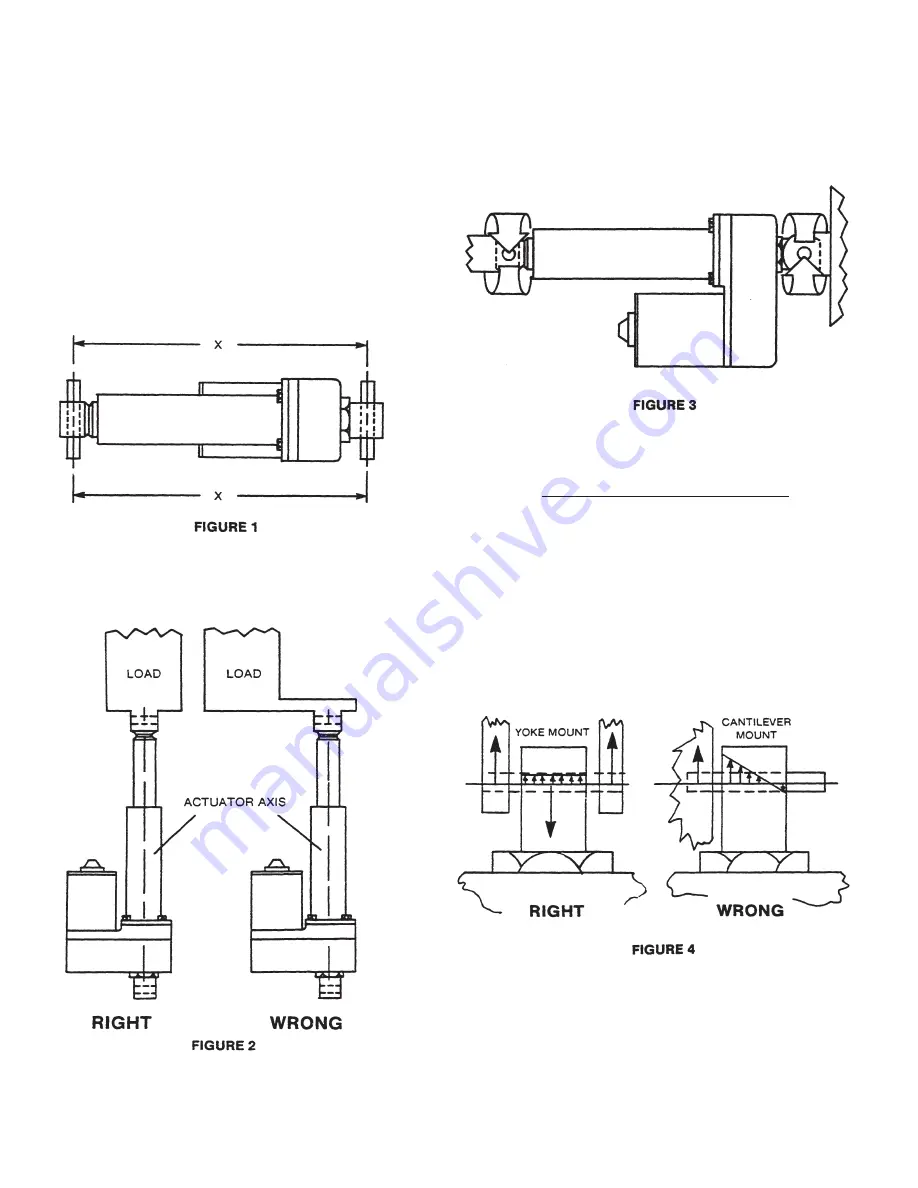

Danaher linear actuators are quickly and easily mounted

by slipping pins through the holes on each end of the unit

and into brackets on the machine frame and the load.

Half inch diameter solid pins provide maximum holding

strength and a retaining or cotter pin on each end will

prevent the solid pin from falling out of its mounting

bracket. Roll or spring type mounting pins should be

avoided. The mounting pins must be parallel to each

other as shown in Figure 1. Pins which are not parallel to

each other may cause the actuator to bind.

The load should act along the stroke axis of the actuator

since off center loads may cause binding and lead to

premature failure. See Figure 2.

The actuator mounting brackets must be able to

withstand the torque which is developed when the unit

extends or retracts. Restraining torque required varies

with the model being used. See Figure 3 and the chart

below.

Make sure mounting pins are supported on both ends.

Cantilever mounts are unacceptable. Failure to do so

could shorten the life of the actuator.

NOTE: Do not attempt to mount the Electrak 10 on its cover tube. The tube is not designed to support the

forces required for this type of mounting.

Torque Required

Actuator

In.-Lbs.

D12-05B5

60

D24-05B5

60

D12-20B5

90

D24-20B5

90

Summary of Contents for THOMSON D12-05B5

Page 11: ......